Automatic industrial gel cutting device

An industrial automation and glue cutting technology, which is applied in metal processing and other directions, can solve the problems of glue sticking to the cutter, low degree of automation, inconvenient use, etc., and achieve the effects of simple structure, labor saving, and improved cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

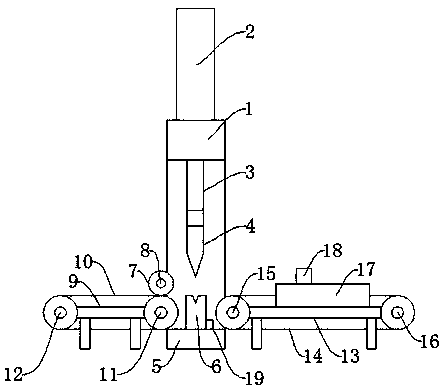

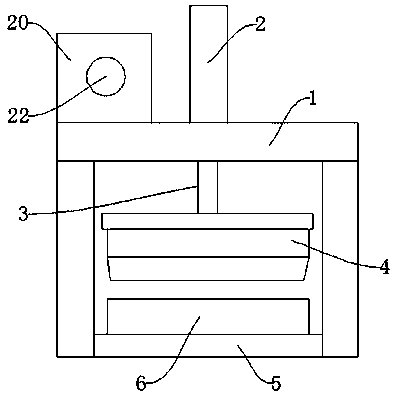

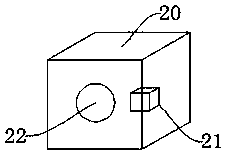

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] Such as Figure 1-Figure 3 As shown, an industrial automatic glue cutting device includes a gantry 1, a lifting motor 2, a lifting rod 3, a cutter 4, and a workbench 5. A lifting motor 2 is arranged on the gantry 1, and a lifting rod is arranged below the lifting motor 2. 3. Lifting rod 3 plays a lifting role. There is a cutter 4 under the lifting rod 3. The cutter 4 is used to cut glue. One side of block 6 is provided with inductor 19, and inductor 19 is used for induction, and gantry frame 1 is provided with first bracket 9 on one side, and first bracket 9 plays a supporting role, and first bracket 9 is provided with first driving wheel 11 on one side, and The other side of a bracket 9 is provided with a first driven wheel 12, the first driven wheel 12 is provided with a first conveyor belt 10, the first driving wheel 11 is provided with a driving wheel 7, the dri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap