Forming equipment and technology of interface-reinforced lightweight concrete

A lightweight concrete and interface enhancement technology, applied in the field of lightweight concrete, can solve the problems of restricting the performance of EPS concrete, weak cohesion, uneven mixing of expanded polystyrene particles and cement slurry, etc., and achieve excellent interface. Performance and usability, ease of operation, and the effect of improving interface performance and usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A molding process for interface-reinforced lightweight concrete, using such as Figure 4 Described forming equipment; Specifically comprise the steps:

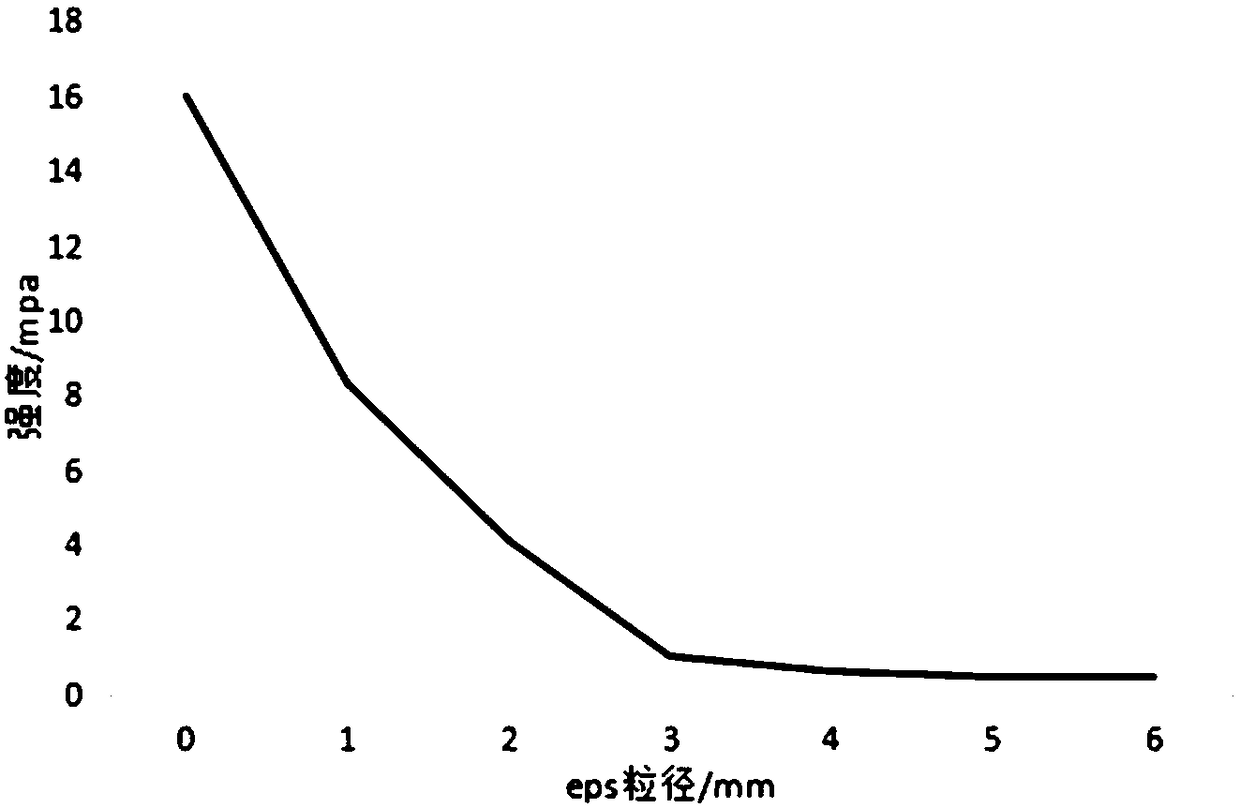

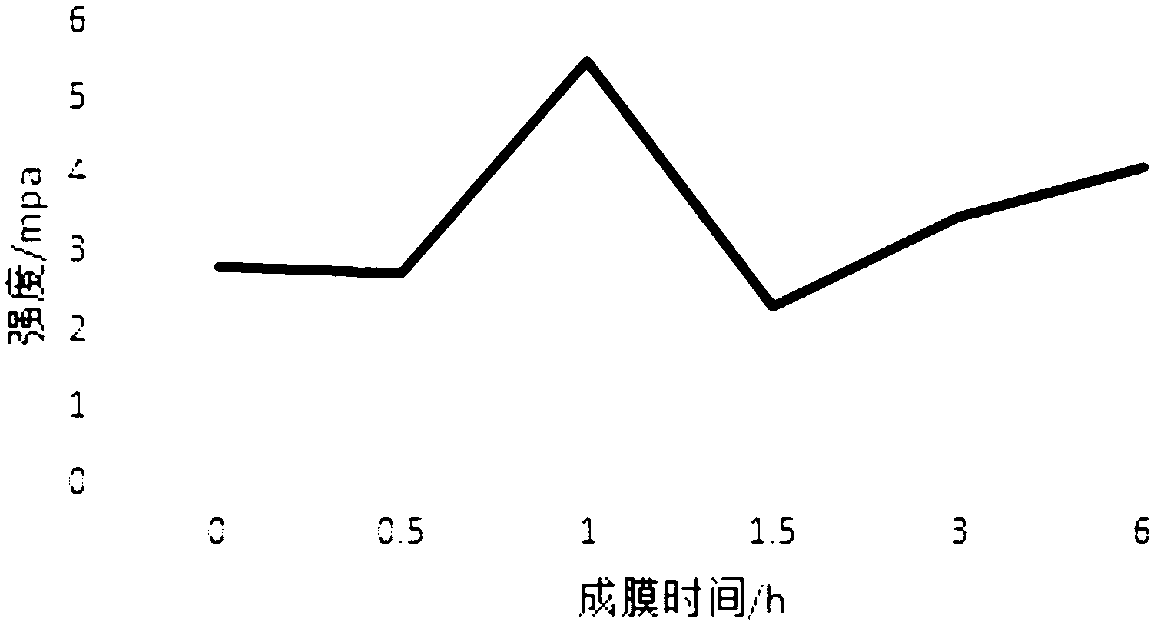

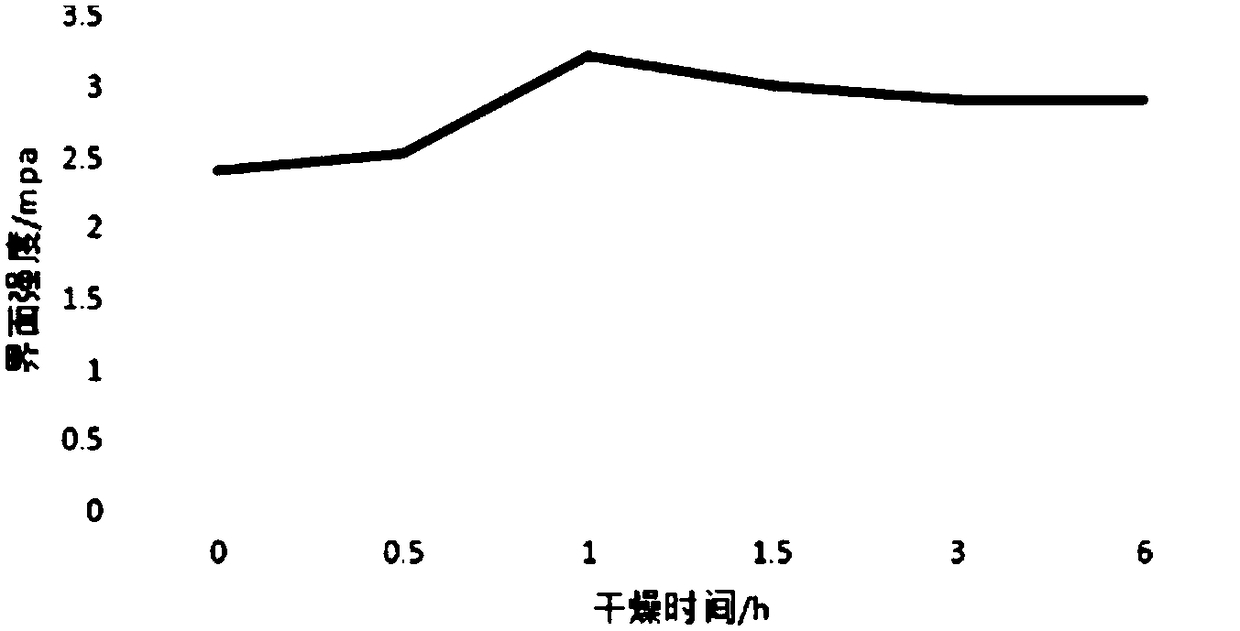

[0044] 1) Weigh the expanded polystyrene particles with a particle size of 3mm through the EPS raw material inlet 1 and transport them to the modified particle coating and drying device 2-3, spray ethylene vinyl acetate (VAE) emulsion on it, and control the ethylene acetate The mass ratio of the amount of vinyl ester (VAE) emulsion sprayed to expanded polystyrene particles is 1:8, and the spraying time is controlled at about 5 minutes; then it is dried at room temperature for 60 minutes (25°C) to obtain ethylene vinyl acetate (VAE) emulsion modification 20 parts of permanent expanded polystyrene particles (parts by weight, the same below), and are delivered to the mixing device 6;

[0045] 2) The raw materials of the cement slurry are weighed through the cement slurry raw material inlet 9 and transported to the cement ...

Embodiment 2~4

[0051] A molding process for interface-reinforced lightweight concrete, the process conditions of which are roughly the same as in Example 1, except that the additions of expanded polystyrene particles are 10g, 30g and 40g respectively; the interface-reinforced lightweight concrete obtained under the formula conditions The performance test results of concrete are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com