Rockfill dam using seamless faceplate and construction method thereof

A technology of rockfill dams and panels, applied in the direction of dams, barrages, barrages, etc., can solve the problems of easy cracks and panel damage of the panels, and achieve the effects of ample construction time, increased life expectancy, and low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

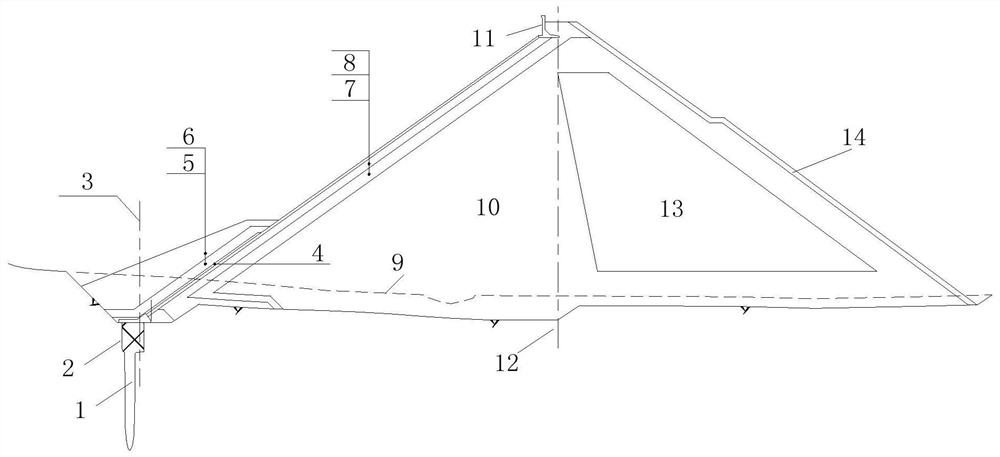

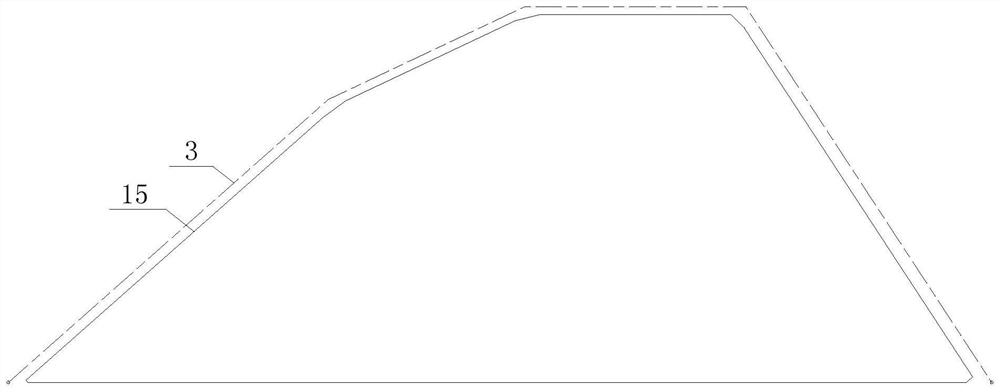

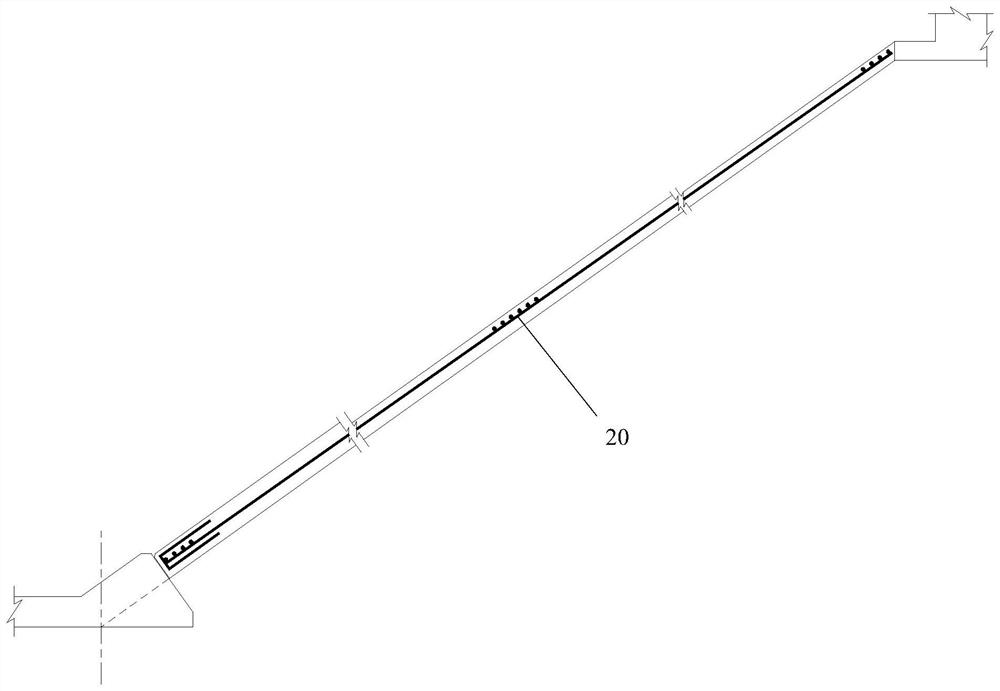

[0020] The present invention will be further described below in conjunction with accompanying drawing.

[0021] Such as Figure 1-4 As shown, the rockfill dam with seamless panels includes the main rockfill area 10, the downstream rockfill area 13, the transition area 7, the cushion area 8, and the seamless panel 18. The seamless panel 18 is made of cement, fine sand, secondary fly ash, polyvinyl alcohol fiber, waterproof emulsion and water reducer, wherein each cubic meter of seamless panel contains 550-560kg of cement, 460-550kg of fine sand, 650~690kg secondary fly ash, 24~28kg polyvinyl alcohol fiber, 10~12kg waterproof emulsion and 20~24kg water reducer. The manufacturing process is: first add cement, fly ash, and sand to the mixer for 2-4 minutes, then add water and water reducer and stir for 4-6 minutes, add polyvinyl alcohol fiber again, stir for 4-6 minutes, and finally add waterproof emulsion , stir for 2-4 minutes. Because the smaller the maximum particle size of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compactness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com