Cement-based high-strength geomechanic model test similar material and preparation method thereof

A technology of geomechanics and model testing, applied in the preparation of test samples, etc., can solve the problem of difficulty in achieving high bulk density, and achieve the effects of low cost, large bulk density and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

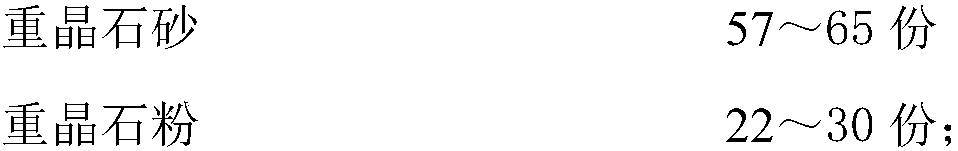

[0025] Component A described in similar materials is based on 100 parts, 2 parts of 32.5 ordinary Portland cement, 62 parts of barite sand, 23 parts of barite powder, 5 parts of silica fume; The amount of water used is 8 parts. Add cement, barite sand, barite powder, and silica fume to the cement mortar mixer. After stirring at low speed for 30 seconds, add water in the second 30 seconds, and then stir at high speed for 60 seconds. Finish.

[0026] The product of the present invention has a bulk density of 2970kg / m 3 , 14 days, 28 days compressive strength were 0.83MPa, 0.97MPa.

Embodiment 2

[0028] Component A described in similar materials is based on 100 parts, 3 parts of 32.5 ordinary Portland cement, 61 parts of barite sand, 22 parts of barite powder sand, and 5 parts of silica fume; The amount of water used is 9 parts. Add cement, barite sand, barite powder, and silica fume to the cement mortar mixer. After stirring at low speed for 30 seconds, add water in the second 30 seconds, and then stir at high speed for 60 seconds. Finish.

[0029] The product of the present invention has a bulk density of 2980kg / m 3 , 14 days, 28 days compressive strength were 1.1MPa, 1.4MPa.

Embodiment 3

[0031] Component A described in similar materials is based on 100 parts, 4 parts of 32.5 ordinary Portland cement, 60 parts of barite sand, 21 parts of barite powder sand, and 5 parts of silica fume; The amount of water used is 10 parts. Add cement, barite sand, barite powder, and silica fume to the cement mortar mixer. After stirring at low speed for 30 seconds, add water in the second 30 seconds, and then stir at high speed for 60 seconds. Finish.

[0032] The product of the present invention has a bulk density of 2990kg / m 3 , 14 days, 28 days compressive strength were 1.4MPa, 1.9MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com