Soft and strong-elasticity sponge and preparation method thereof

An elastic sponge and soft technology, applied in the field of polymers, can solve the problems of easy deformation and poor hand feeling of the sponge, and achieve the effects of strong resilience, simple and easy preparation method, and slow burning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

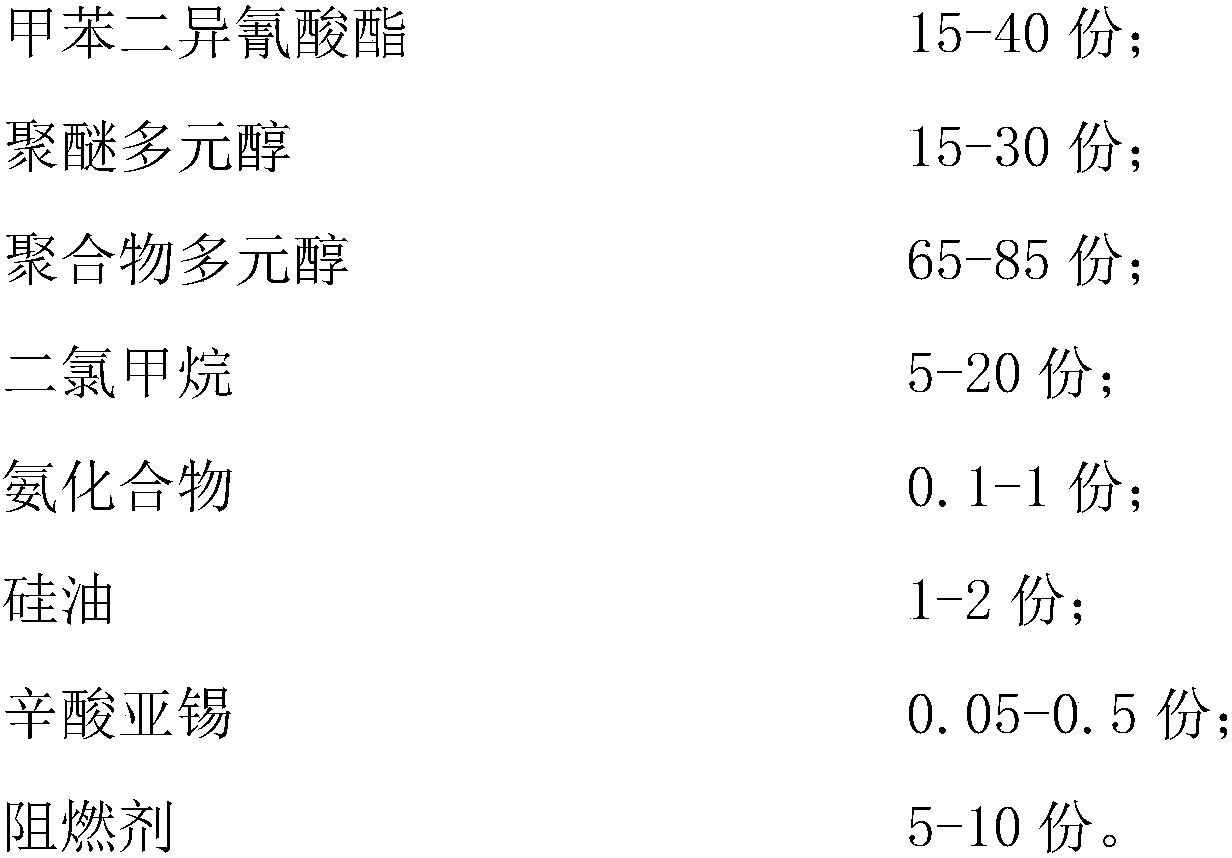

[0024] A soft and strong elastic sponge, comprising the following raw materials in parts by weight:

[0025]

[0026] Further, the flame retardant is one or more of dibromomethane, trichlorobromomethane or dichlorobromomethane.

[0027] A preparation method of a soft and strong elastic sponge, comprising the steps of:

[0028] (1) Primary polymerization: mix the polyether polyol, polymer polyol, dichloromethane, ammonia compound, silicone oil, stannous octoate, flame retardant of said weight portion, stir to obtain mixture A, and stir rapidly for 3 seconds;

[0029] (2) secondary polymerization, in the reaction solution A described in step (1), add the toluene diisocyanate of described weight part, obtain reaction solution B;

[0030] (3) Curing and molding: quickly pour the reaction solution B described in step (2) into the mold and react for 8 minutes, and then solidify and mold to obtain a high-hardness sponge.

[0031] Further, the temperature of polyether polyol, po...

Embodiment 2

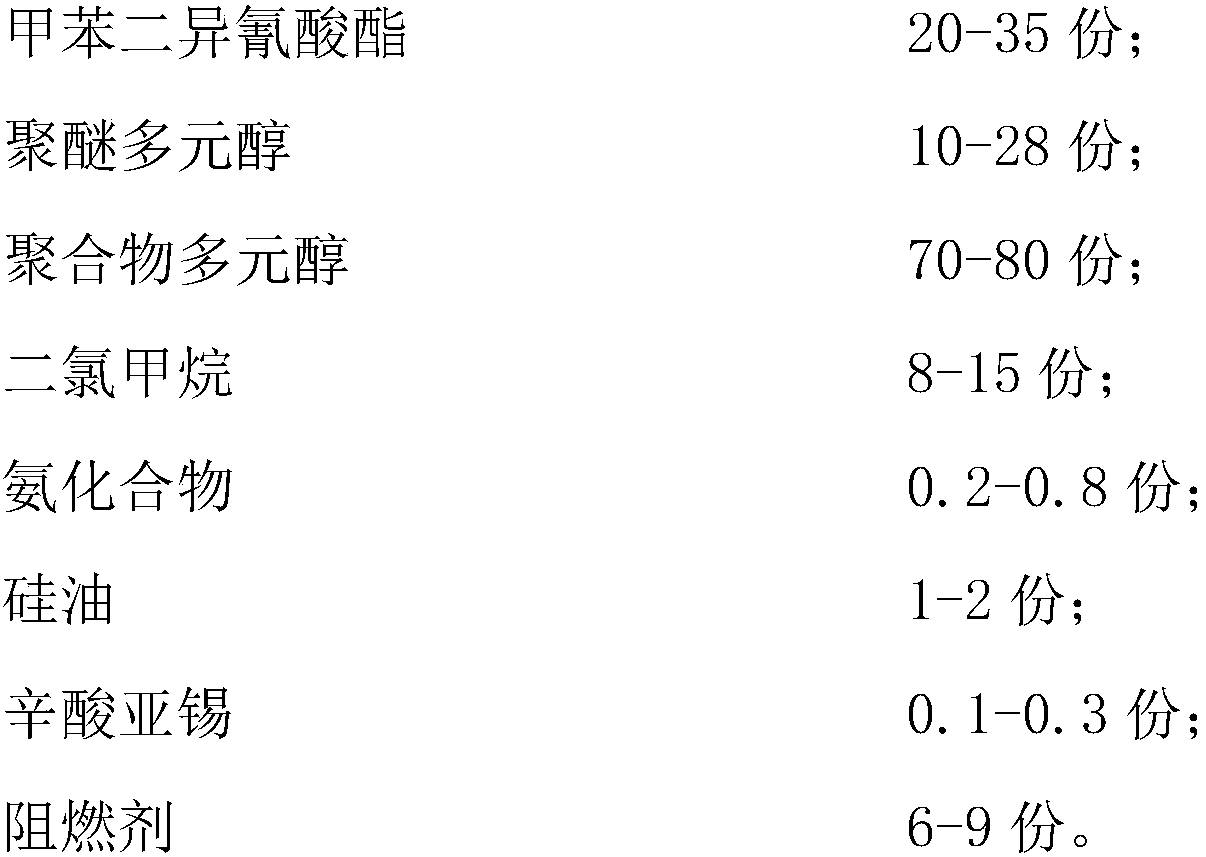

[0035] A soft and strong elastic sponge, comprising the following raw materials in parts by weight:

[0036]

[0037]

[0038] Further, the flame retardant is one or more of dibromomethane, trichlorobromomethane or dichlorobromomethane.

[0039] A preparation method of a soft and strong elastic sponge, comprising the steps of:

[0040] (1) Primary polymerization: mix the polyether polyol, polymer polyol, dichloromethane, ammonia compound, silicone oil, stannous octoate, flame retardant of said weight portion, stir to obtain mixture A, and stir rapidly for 5 seconds;

[0041] (2) secondary polymerization, in the reaction solution A described in step (1), add the toluene diisocyanate of described weight part, obtain reaction solution B;

[0042] (3) Curing and forming: quickly pour the reaction liquid B described in step (2) into the mold and react for 15 minutes, and then solidify and form to obtain a high-hardness sponge.

[0043] Further, the temperature of the polye...

Embodiment 3

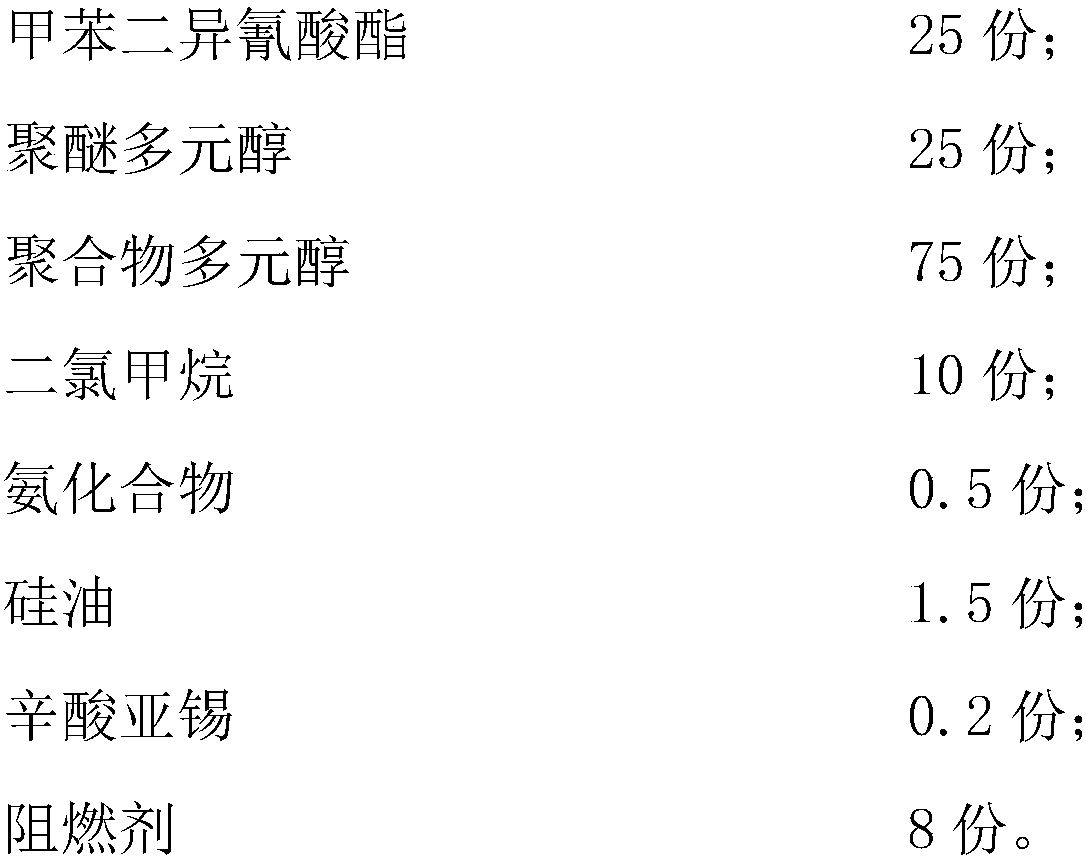

[0047] A soft and strong elastic sponge, comprising the following raw materials in parts by weight:

[0048]

[0049]

[0050] Further, the flame retardant is one or more of dibromomethane, trichlorobromomethane or dichlorobromomethane.

[0051] A preparation method of a soft and strong elastic sponge, comprising the steps of:

[0052] (1) Primary polymerization: mix the polyether polyol, polymer polyol, dichloromethane, ammonia compound, silicone oil, stannous octoate, flame retardant of said weight portion, stir to obtain mixture A, and stir rapidly for 5 seconds;

[0053] (2) secondary polymerization, in the reaction solution A described in step (1), add the toluene diisocyanate of described weight part, obtain reaction solution B;

[0054] (3) Curing and forming: quickly pour the reaction liquid B described in step (2) into the mold and react for 15 minutes, and then solidify and form to obtain a high-hardness sponge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com