Artificial leather capable of being directly embossed and preparation method thereof

An artificial leather and embossing technology, applied in the field of artificial leather, can solve problems such as unsatisfactory decorative effects, difficulty in carrying patterns, and softening of decorative lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

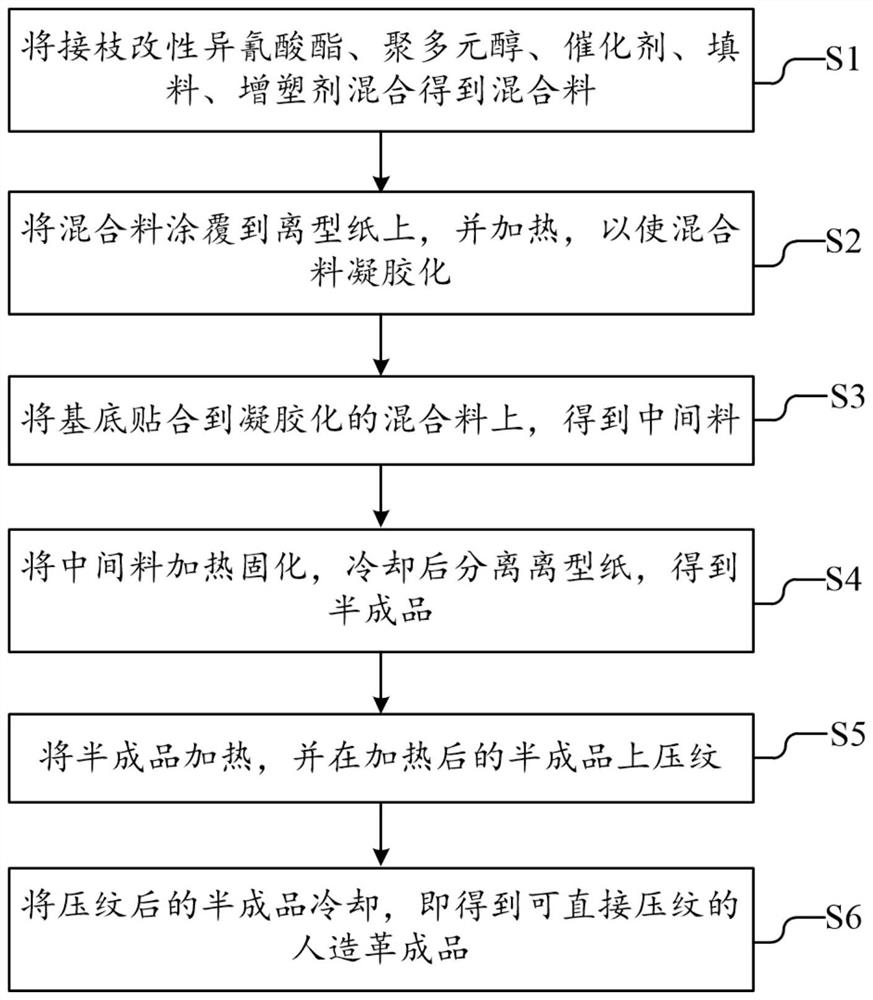

[0046] refer to figure 1 , the invention provides a kind of preparation method of directly embossed artificial leather, it comprises the following steps:

[0047] S1: Mix grafted modified isocyanate, polypolyol, catalyst, filler, and thermoplastic powder to obtain a compound;

[0048] Specifically, S1 includes:

[0049] S11: react isocyanate, polypolyol and catalyst at 70-120°C to obtain grafted modified isocyanate;

[0050] Wherein, the formula of the grafted modified isocyanate includes the following raw materials in parts by weight: 80-100 parts of isocyanate, 80-120 parts of polypolyol, and 0.05-0.5 part of catalyst.

[0051] Among them, the isocyanate can be selected from 4,4-diphenylmethane diisocyanate, toluene diisocyanate, isophorone diisocyanate, hexamethylene diisocyanate, p-isopropylphenyl isocyanate and by introducing uretdione, amino methyl 4,4-diphenylmethane diisocyanate, toluene diisocyanate, isophorone diisocyanate, hexamethylene diisocyanate, p-isopropyl ...

Embodiment 1

[0083] This embodiment provides a method for preparing artificial leather that can be directly embossed, specifically including:

[0084] (1) Mix 18 parts of grafted modified isocyanate, 82 parts of polypolyol, 0.08 part of catalyst, 25 parts of filler, 45 parts of thermoplastic powder, and 0.2 part of foam stabilizer (LM2003, Xi'an Leiming Chemical Technology Co., Ltd.) to obtain Mixture;

[0085] Wherein, the polypolyol is polyester polyol (C1120, Xi'an Leiming Chemical Technology Co., Ltd.), and the filler is Shuangfei powder.

[0086] Among them, the graft modified isocyanate is prepared by reacting 100 parts of TDI with 80 parts of polyester polyol and 0.2 parts of catalyst at 110°C.

[0087] (2) Coating the mixture on release paper and heating at 100°C to gel the mixture;

[0088] (3) Bond the substrate (sandwich, Shenzhen Guanghuida Leather Co., Ltd.) to the gelled mixture to obtain an intermediate material;

[0089] (4) heating and solidifying the intermediate mater...

Embodiment 2

[0095] This example provides a method for preparing artificial leather that can be directly embossed. The difference from Example 1 is that polyether polyol (EP330, Xi'an Leiming Chemical Technology Co., Ltd.) is used as the polypolyol in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear force | aaaaa | aaaaa |

| Softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com