A range hood impeller using ultrasonic cleaning

An ultrasonic and range hood technology, which is applied in the removal of oil fume, components and applications of pumping devices for elastic fluids, etc., can solve the problems of difficult collection of waste water, damaged impellers, complicated devices, etc., to achieve convenient operation, increase life, The effect of maintaining dynamic balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

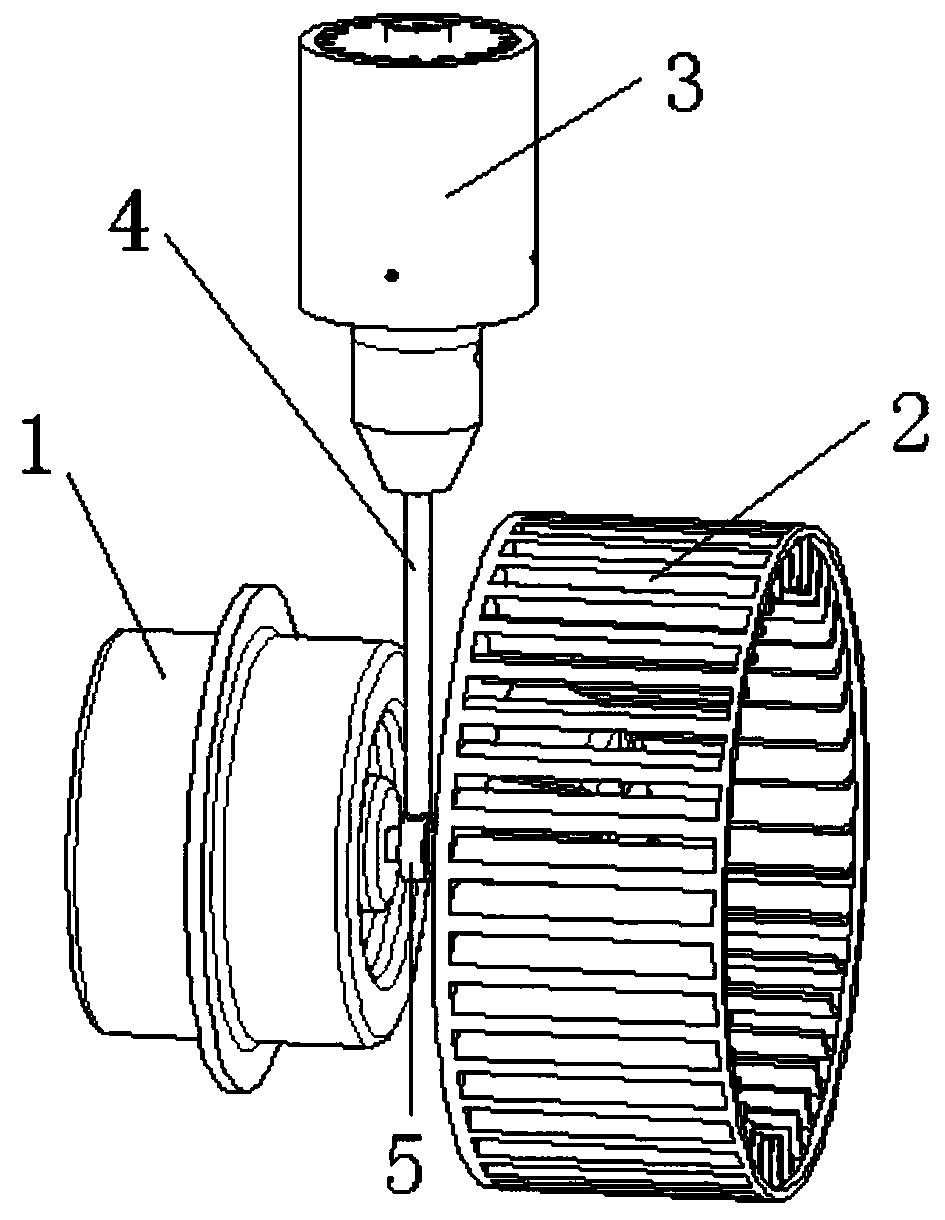

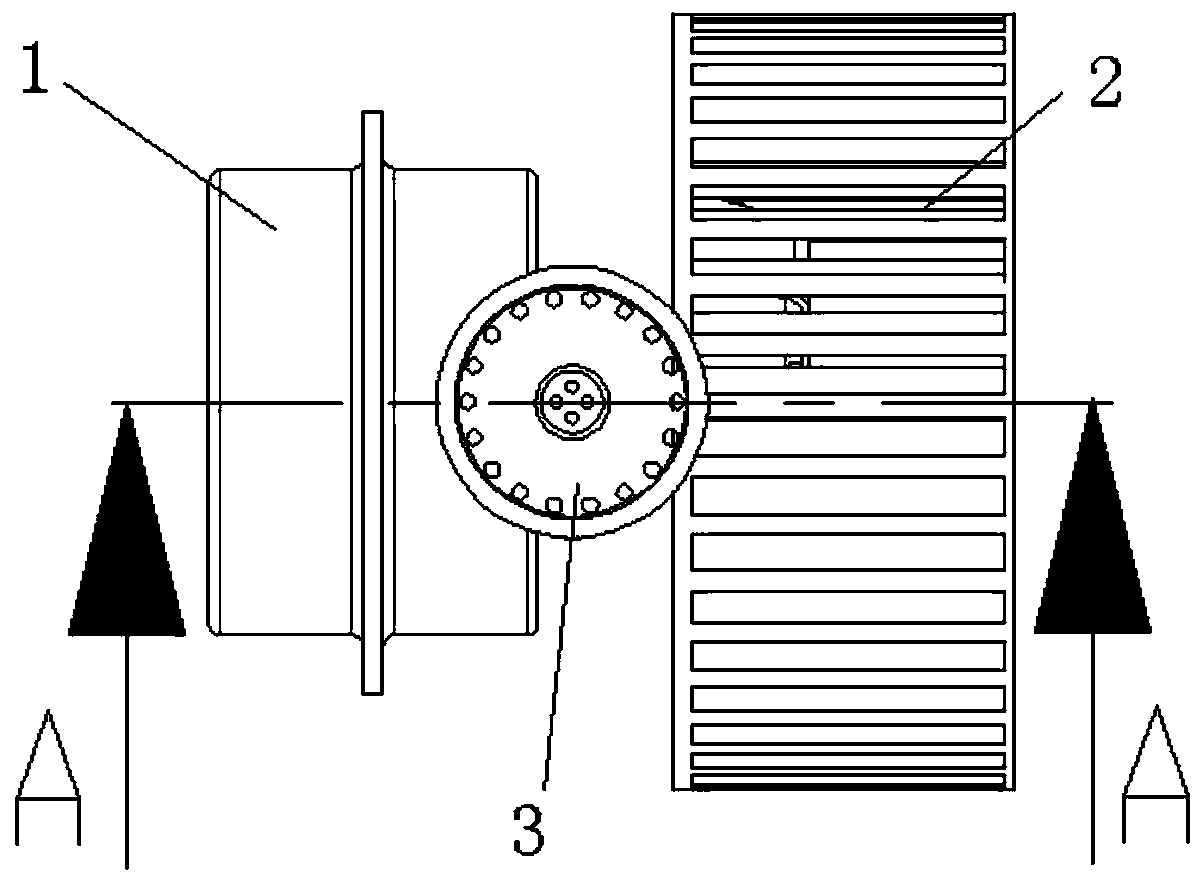

[0026] Such as Figure 1-4 As shown, this embodiment provides a range hood impeller using ultrasonic cleaning, including a motor 1 , an impeller 2 and an ultrasonic device 3 , the motor 1 is connected to the impeller 2 through an output shaft 11 , and the ultrasonic device 3 is used to vibrate the impeller 2 .

[0027] The impeller 2 includes a bottom plate 21 on which a hub 22 is arranged. The center of the hub 22 is provided with a threaded bushing 23 . The output shaft 11 passes through the bottom plate 21 and is threadedly connected to the threaded bushing 23 .

[0028] A bearing 5 is arranged on the output shaft 11 , and the ultrasonic device 3 is fixedly connected to the bearing 5 through a connecting rod 4 . By setting the bearing 5, when the motor 1 is started, the rotation of the output shaft 11 does not affect the state of the ultrasonic device 3 .

[0029] When the impeller 2 needs to be cleaned, the ultrasonic device 3 vibrates and transmits the vibration to the i...

Embodiment 2

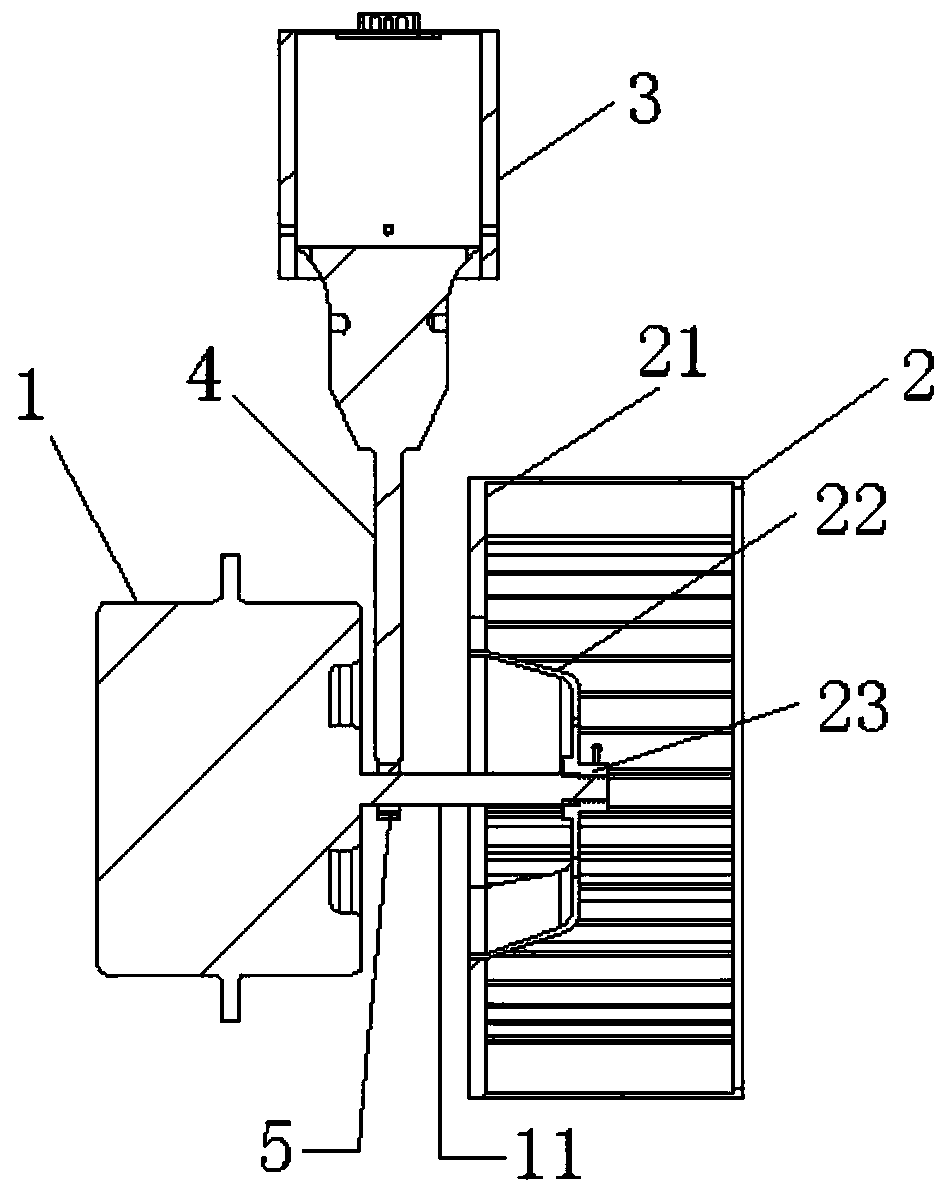

[0031] Such as Figure 5-7 As shown, this embodiment provides a range hood impeller using ultrasonic cleaning, including a motor 1 , an impeller 2 and an ultrasonic device 3 , the motor 1 is connected to the impeller 2 through an output shaft 11 , and the ultrasonic device 3 is used to vibrate the impeller 2 .

[0032] The impeller 2 includes a bottom plate 21 on which a hub 22 is arranged. The center of the hub 22 is provided with a threaded bushing 23 . The output shaft 11 passes through the bottom plate 21 and is threadedly connected to the threaded bushing 23 .

[0033] One end of the ultrasonic device 3 is provided with a connecting portion 6, and the connecting portion 6 is threadedly connected with the threaded sleeve 23, thereby fixing the ultrasonic device 3 and the impeller 2 together. When the impeller 2 rotates, the ultrasonic device 3 rotates with the impeller. In order to support and fix the ultrasonic device 3 , the other end of the ultrasonic device 3 is sheath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com