Constant-capacity combustion pressure testing device for micro-nano energetic material

A technology of constant volume combustion and pressure testing, which is applied in the direction of chemical analysis using combustion, can solve problems such as inapplicability, and achieve the effects of convenient operation, small size and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

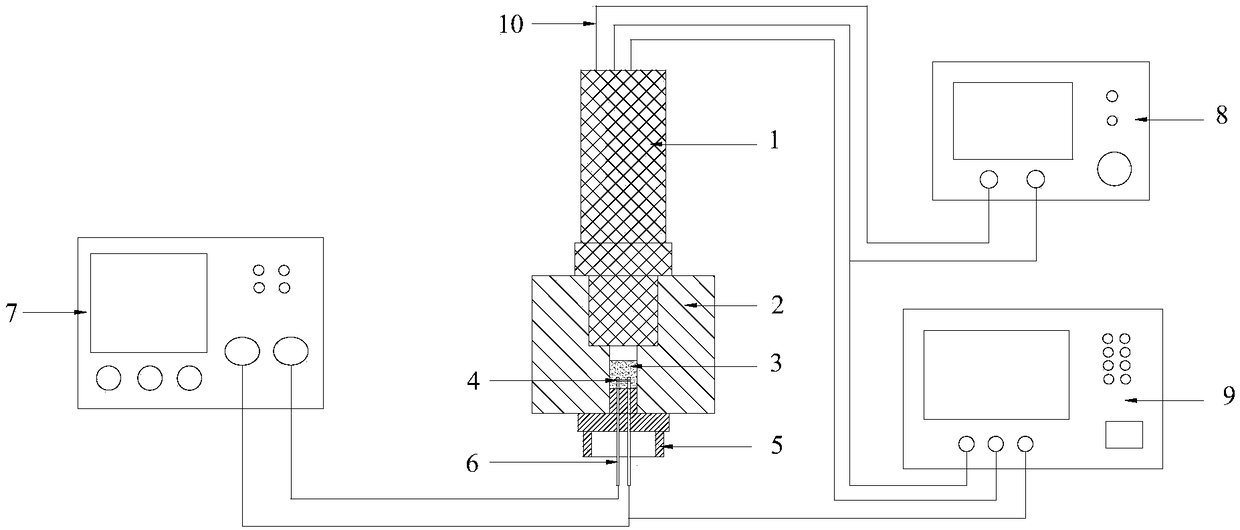

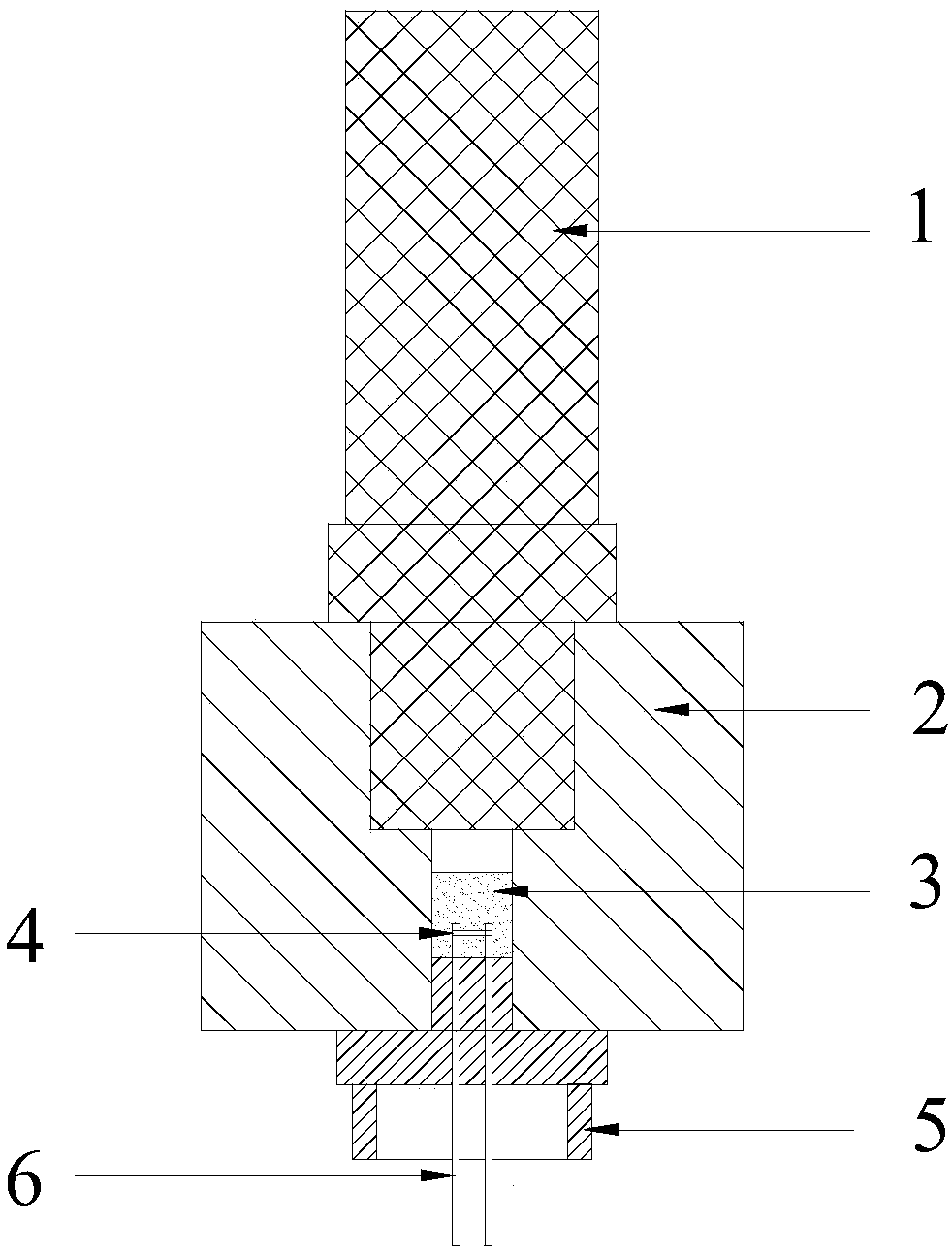

[0025] to combine Figure 1-5 , a constant-volume combustion pressure test device for micro-nano energetic materials is:

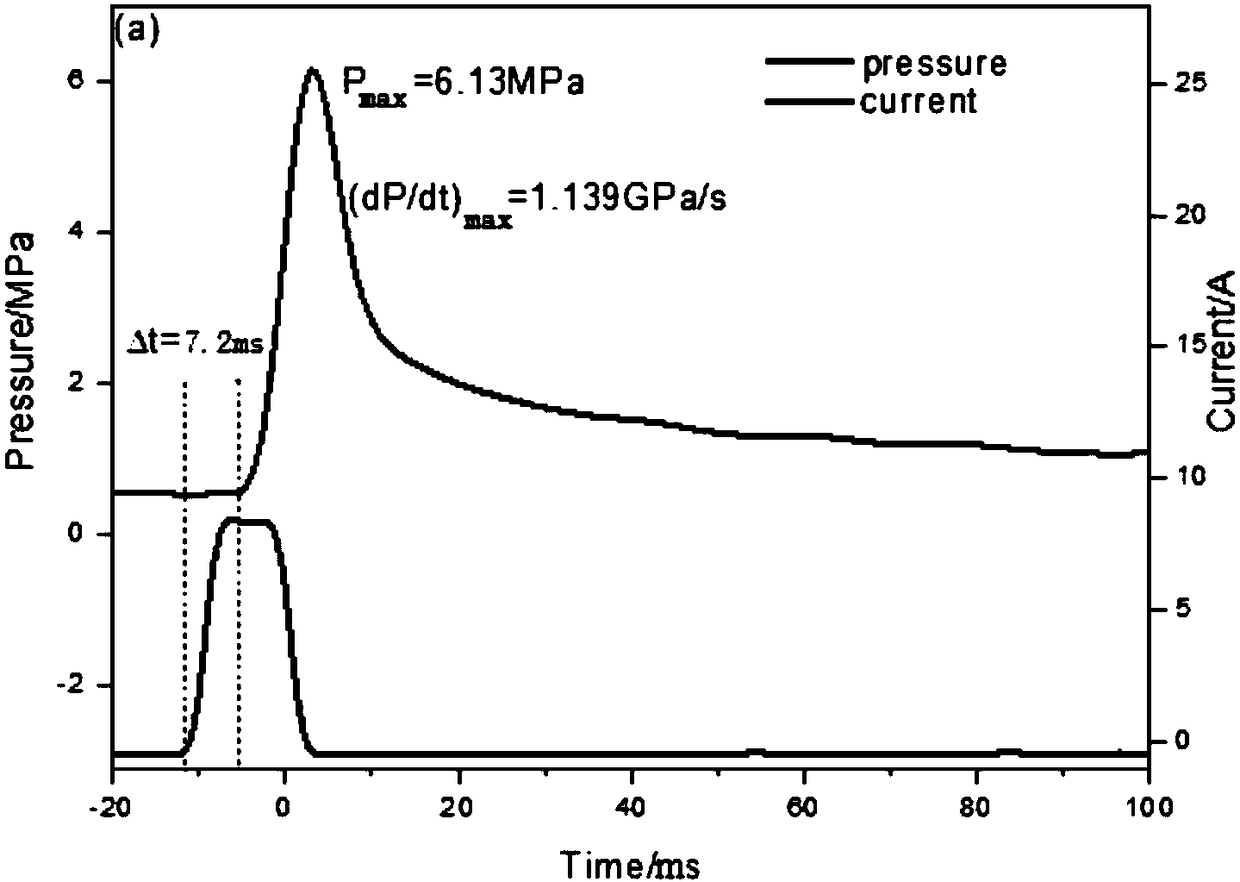

[0026] Miniature airtight explosive device 2, nut type igniter 5, Co 3 o 4 / Al nanometer thermite 3 and piezoelectric sensor 1, nut type igniter 5 are fixedly connected with the combustion chamber of miniature airtight explosive device 2; Two chambers with different sizes, the chamber with the larger aperture is connected to the piezoelectric sensor 1, and the piezoelectric sensor 1 closes the opening of the chamber; the chamber with the smaller aperture is used as the combustion chamber; the volume of the combustion chamber is close to 0.2ml; co 3 o 4 / Al nanometer thermite 3 promptly fills in the combustion chamber of miniature airtight explos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com