AGM membrane for lead-carbon battery and preparation method of AGM membrane

A lead-carbon battery and diaphragm technology, applied to lead-acid batteries, battery components, circuits, etc., to achieve the effects of easy control, high tensile strength, and good wet-state pressure-holding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

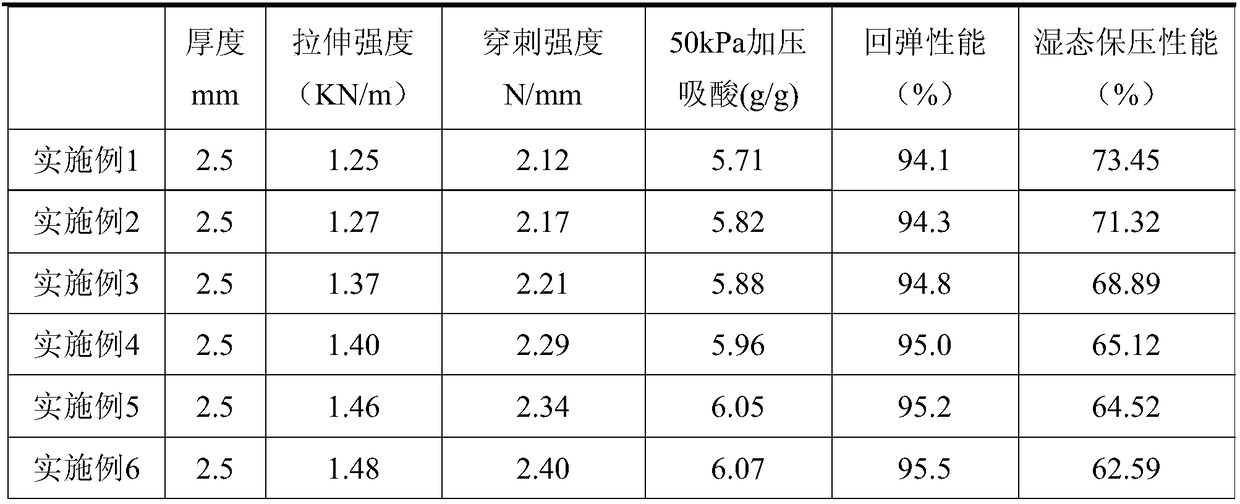

Examples

Embodiment 1

[0033] Take 10 parts of high-alkali glass fibers with a monofilament diameter of 0.5-0.8 μm and 90 parts of high-alkali glass fibers with a monofilament diameter of 1.2-2.0 μm, and prepare an AGM diaphragm according to the above method. Among them: the decomposing time is 12 minutes; the drying temperature is 200° C.; the drying time is 8 minutes; the mass concentration of concentrated sulfuric acid is 78%.

Embodiment 2

[0035] Take 10 parts of high-alkali glass fibers with a monofilament diameter of 0.5-0.8 μm and 90 parts of high-alkali glass fibers with a monofilament diameter of 1.2-2.0 μm, and prepare an AGM diaphragm according to the above method. Among them: the decomposing time is 15 minutes; the drying temperature is 220° C.; the drying time is 7 minutes; the mass concentration of concentrated sulfuric acid is 85%.

Embodiment 3

[0037] Take 20 parts of high-alkali glass fibers with a single-filament diameter of 0.5-0.8 μm and 80 parts of high-alkali glass fibers with a single-filament diameter of 1.2-2.0 μm, and prepare an AGM diaphragm according to the above method. Among them: the decomposing time is 12 minutes; the drying temperature is 220° C.; the drying time is 7 minutes; the mass concentration of concentrated sulfuric acid is 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com