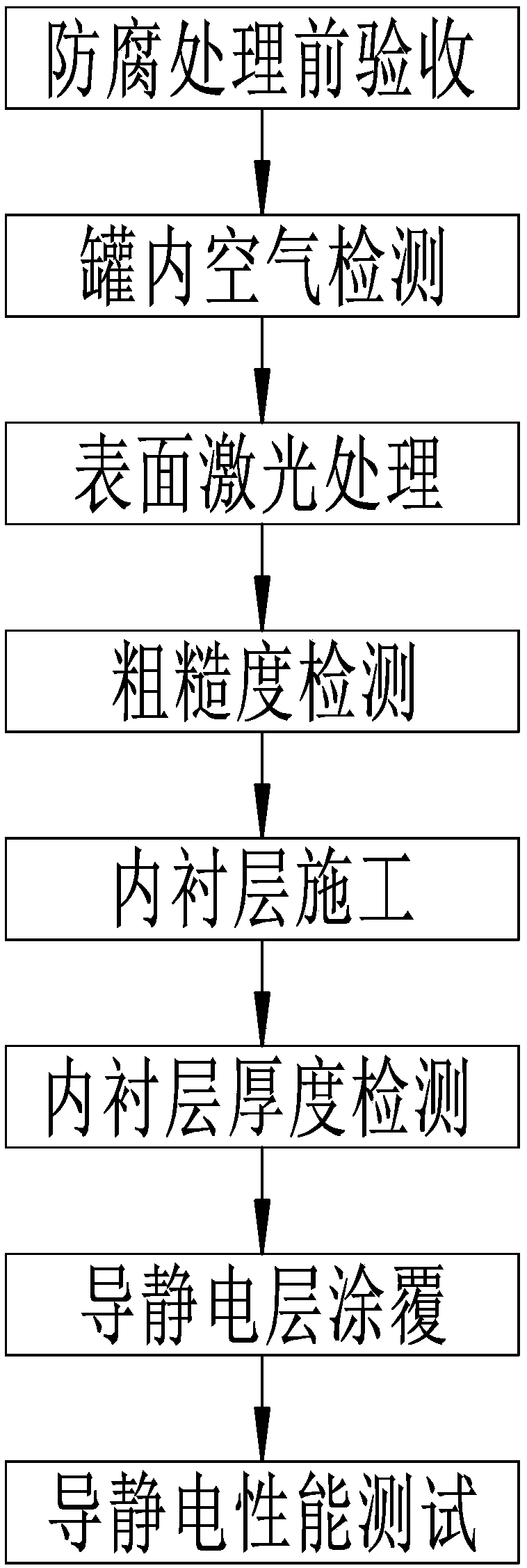

Anti-corrosive construction process for inner surface of oil tank in service based on laser technology

A technology of laser technology and construction technology, which is applied in the field of anti-corrosion construction technology on the inner surface of oil tanks in service, can solve the problems of not meeting the roughness of the inner lining layer, easy to pollute the environment, and narrow space in the tank, and achieve the best market promotion and The effect of low requirements on application and site conditions and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

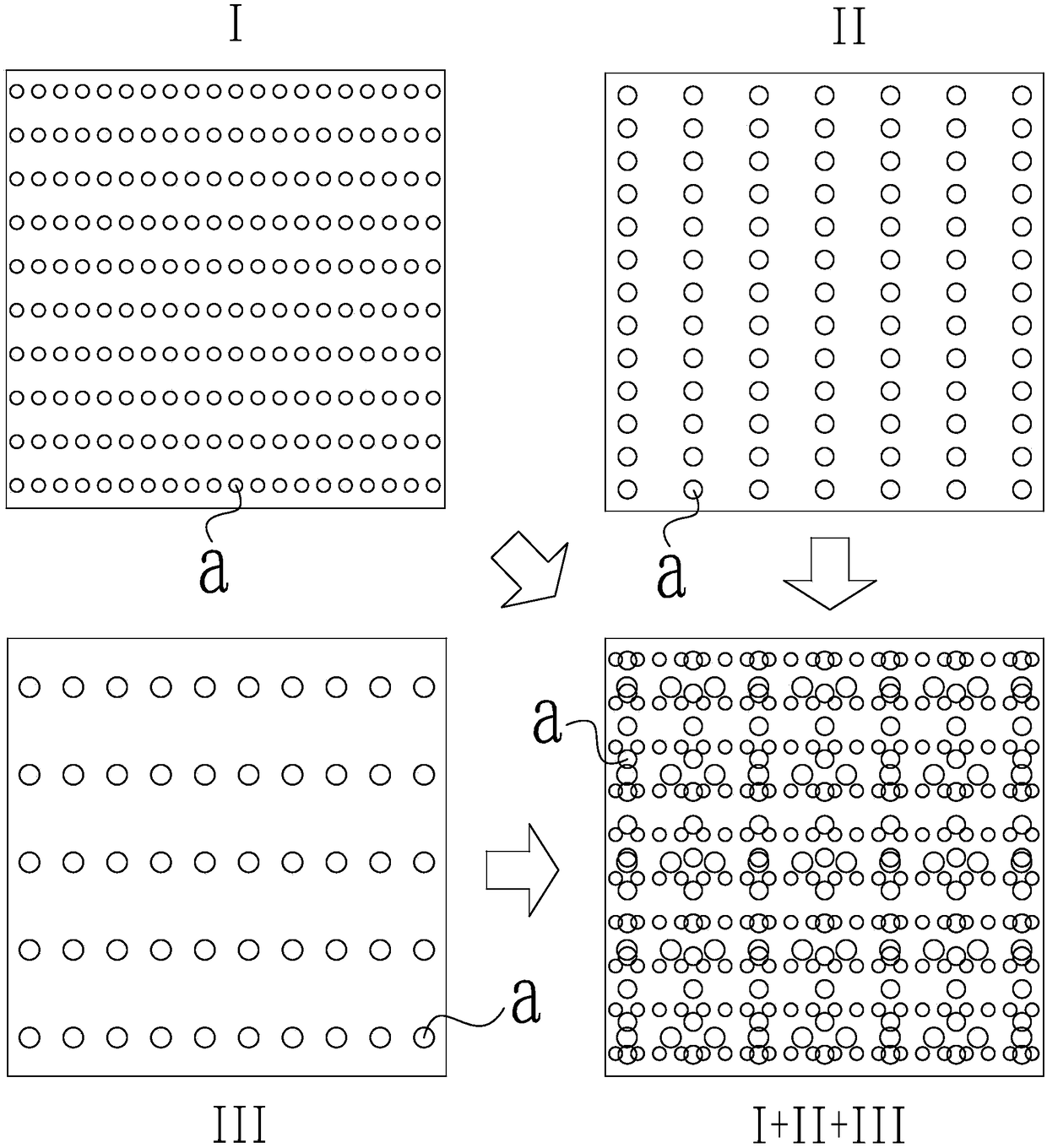

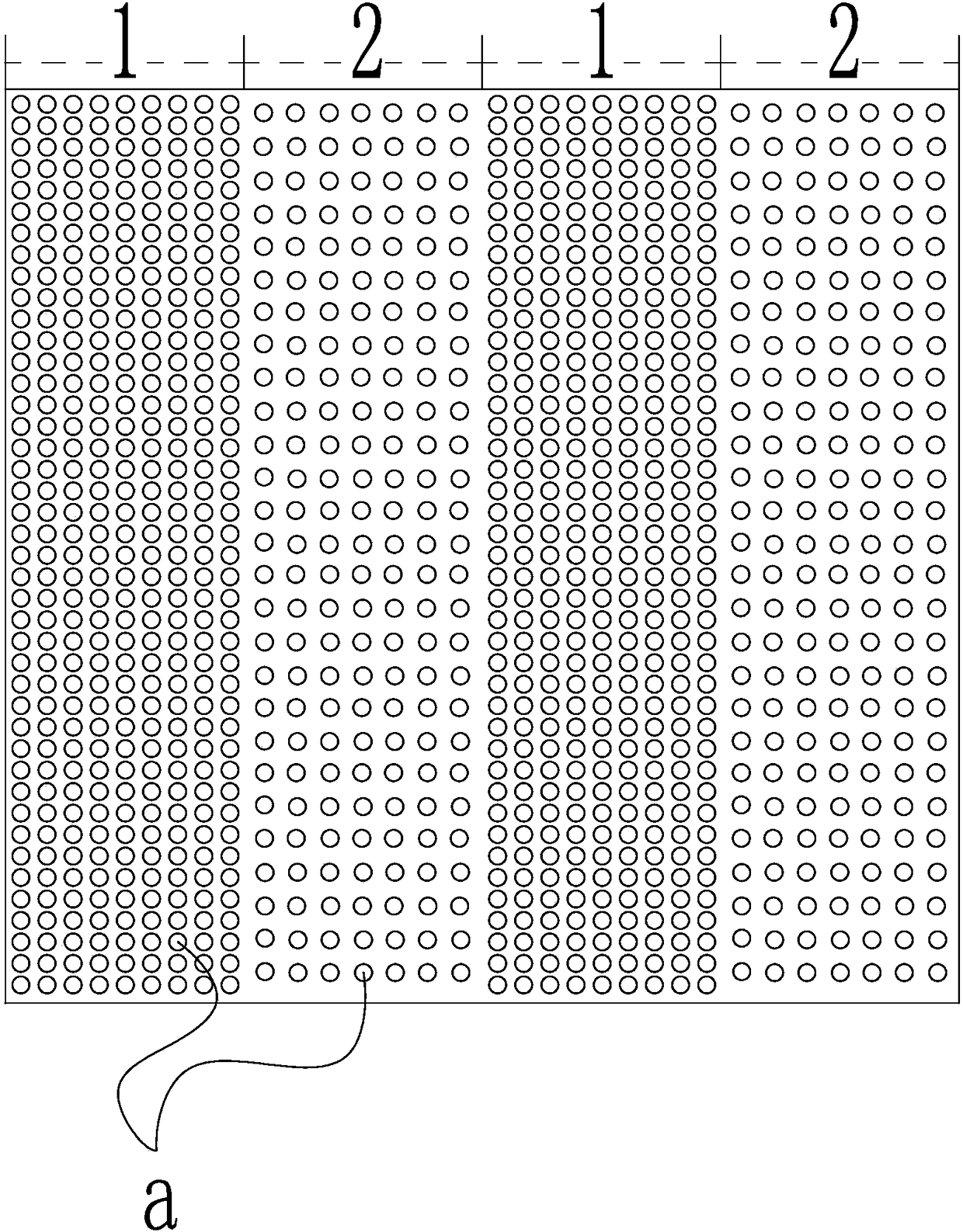

[0070] See figure 2 , the micro-surface structure is composed of pits a arranged in disorder, forming a disordered rough surface on the inner surface of the tank, so as to greatly improve the adhesion of the inner lining. Specifically, the micro-surface structure is obtained by scanning the inner surface of the tank at least twice by the laser generating equipment, and the path of any laser scanning is perpendicular to the path of the previous laser scanning, that is, horizontal and vertical alternate construction. Further, and the density of the pits a formed by any laser scanning is less than the density of the pits a formed by the previous laser scanning, the size of the pits a formed by any laser scanning is greater than the pits formed by the previous laser scanning the size of a. The inner surface of the tank is rapidly formed with pits a of different sizes and arranged in disorder, so that the roughness of the inner surface of the tank reaches the anti-corrosion stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com