Wet-dry dual-use photovoltaic module cleaning brush

A photovoltaic module, wet and dry dual-use technology, applied in cleaning methods using tools, cleaning methods using liquids, photovoltaic power generation, etc., can solve the problems of unreachable height, heavy weight, and low cleaning efficiency, and the length can be reached Effect of efficiency improvement of adjustment, light weight, cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

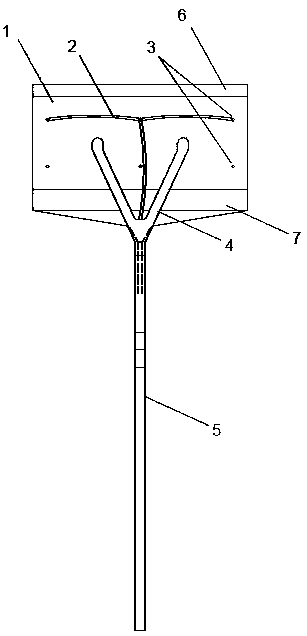

[0034] Such as figure 2 As shown, a wet and dry photovoltaic module cleaning brush provided by the present invention includes a brush head and a gripping part connected to the brush head, the brush head includes a housing, the lower surface of the housing is a cleaning surface, and the lower surface Several sets of brushes are arranged on the top; the brushes are soft brushes and / or hard brushes.

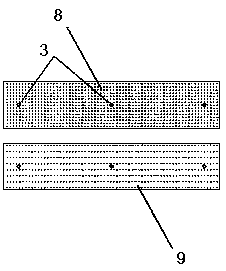

[0035] In this example, if image 3 As shown, at least one bristle brush head 9 and one soft bristle brush head 8 are arranged on the brush head, and two replaceable brush heads can be selected. Pull the port to connect or connect to the body of the brush head through Velcro; the bristle or soft bristle brush head is limited by the thickness of the bristle fiber. Generally speaking, the same kind of fiber is called hard bristle if it is larger than 3mm, and it is called bristle if it is less than 3mm. Soft bristles; however, there is no strict distinction between the softness and...

Embodiment 2

[0040] The washing and cleaning part also includes a wiper 6, which is a scraper, and the scraper is approximately perpendicular to the surface of the cleaning object, detachably connected to the lower surface of the brush head, and rotates around the joint.

[0041] Here, in this embodiment, the connection mode between the wiper 6 and the brush head is selected from one of the following methods, the wiper 6 is provided with a first arc-shaped protrusion, and the lower surface of the brush head is provided with a first U-shaped card slot, the wiper 6 is connected in the first card slot of the brush head through a protrusion; or the wiper 6 is connected in the screw hole of the brush head by a screw; or the wiper 6 is connected by magic Sticker is connected with brush head. The detachable connection between the wiper 6 and the brush head is not limited to the above-mentioned several implementation methods, and plug-in ports, magnetic adsorption, etc. can also be used, and any c...

Embodiment 3

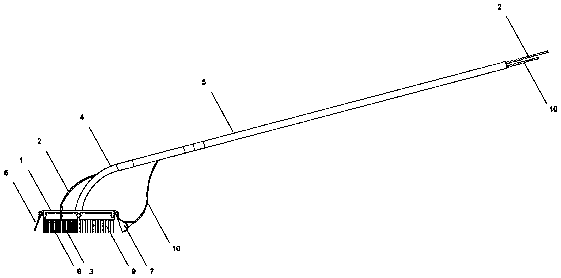

[0045] Such as figure 1 As shown, on the basis of washing the cleaning brush with water in Example 2, this embodiment also provides an implementation that can recycle the sewage cleaned by the cleaning brush. Specifically, the cleaning brush also includes a sewage recovery component. The sewage recovery component is a sewage recovery device 7 arranged on the lower surface of the casing for recycling sewage, and the sewage recovery device 7 is connected to a return pipe 10 . The sewage recovery device 7 is connected to the return pipe 10 . The water inlet pipe 2 and the water return pipe 10 pass through the holding part. There is a detachable connection between the sewage recovery device 7 and the housing.

[0046] The sewage recovery device 7 is arranged on the edge of the lower surface of the shell, which is funnel-shaped, and its opening direction faces the inside of the cleaning area; the sewage recovery device 7 is provided with a second arc-shaped protrusion, and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com