Winding and coating device for anti-corrosion composite belt of elbow pipe winding machine

A technology of coating device and composite tape, which is applied in the direction of pipeline anti-corrosion/rust protection, damage protection, pipeline protection, etc., can solve the problem that the heating temperature of polyethylene composite tape cannot be reached, the tension control of polyethylene composite tape is uneven, and the reduction of polymerization Solve problems such as the winding quality of vinyl composite tapes, and achieve the effects of improving the quality of winding wrapping, improving the uniformity of tension control, and enhancing the bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

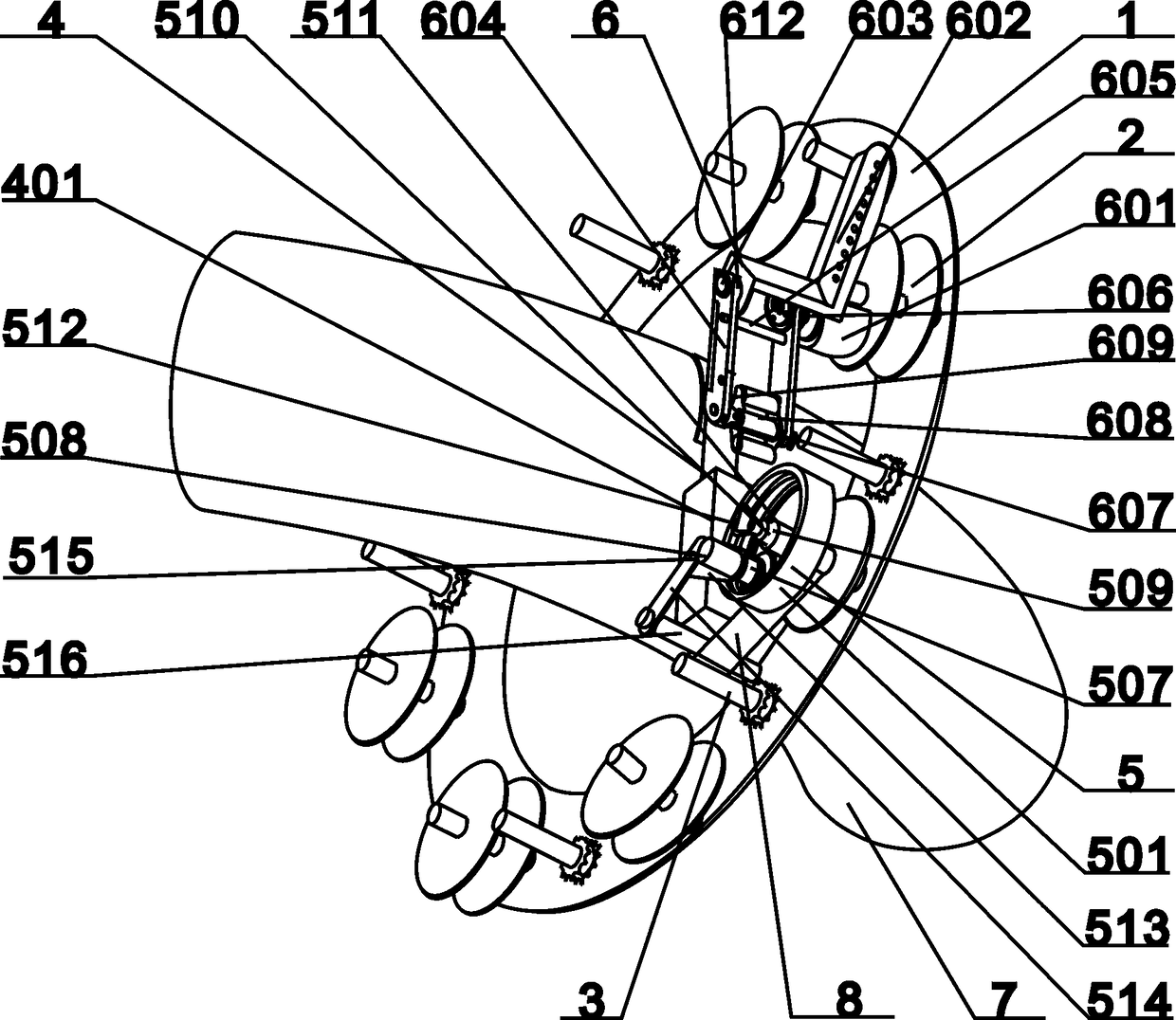

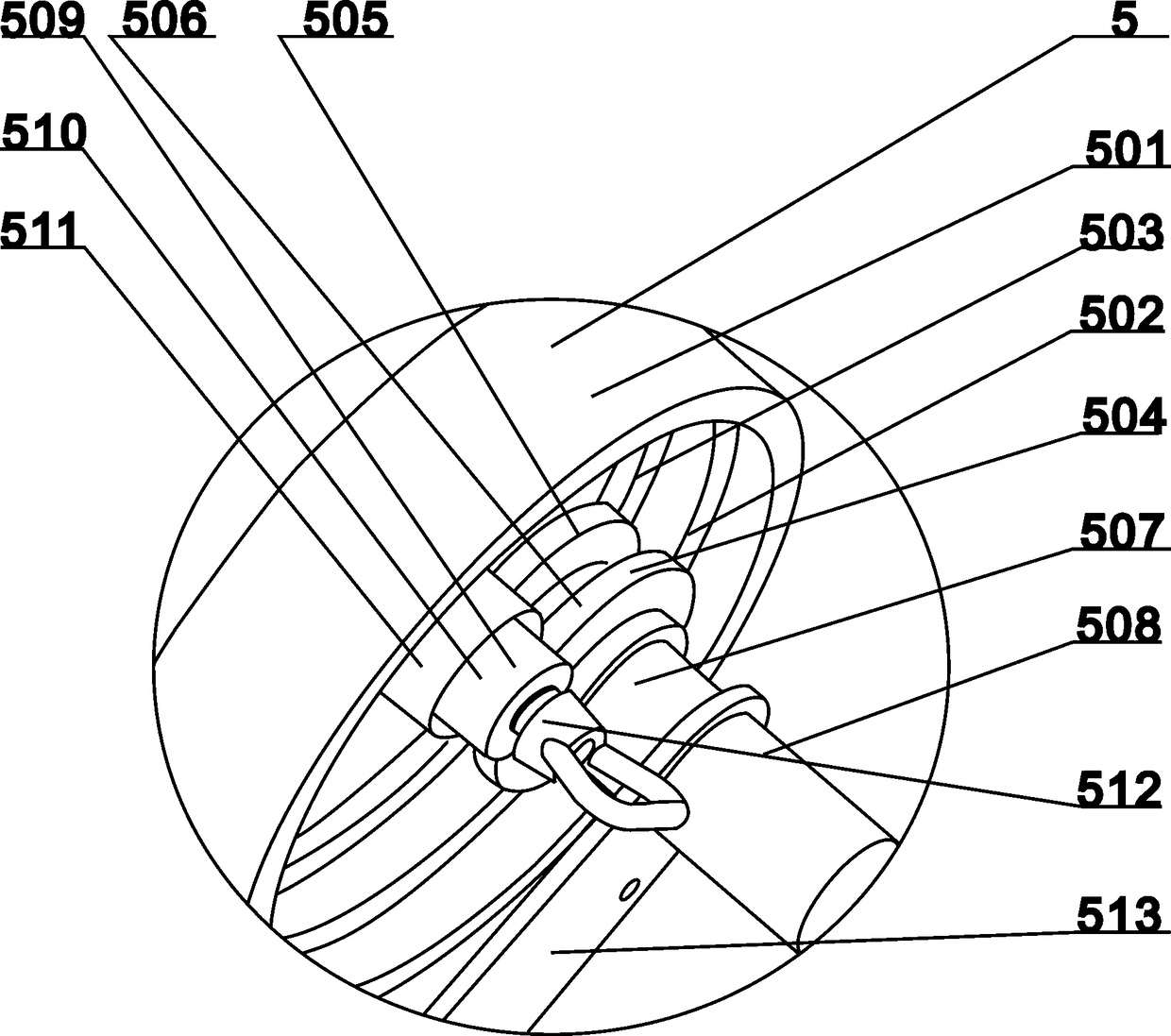

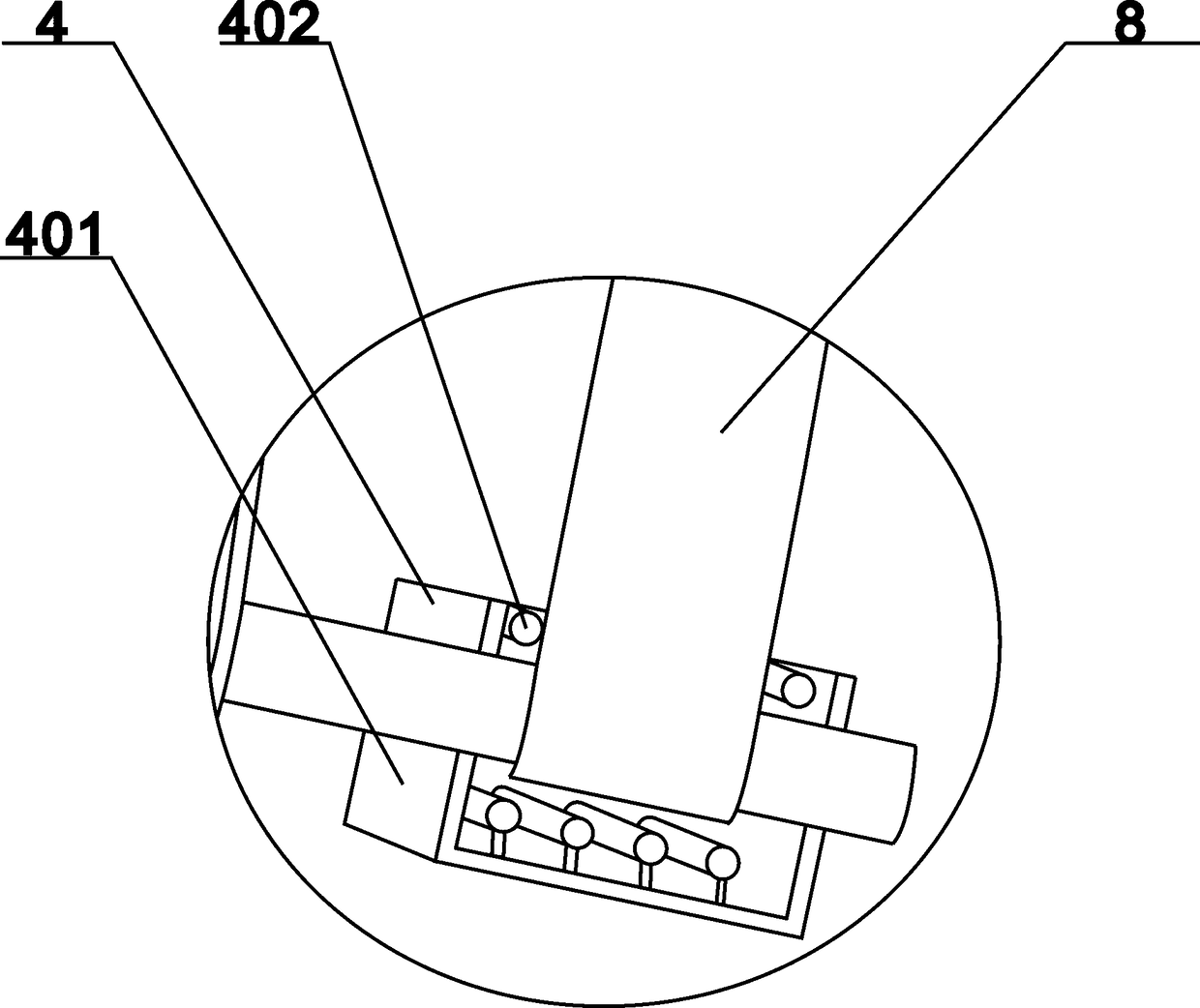

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] As shown in the figure, a winding and coating device for an anti-corrosion composite tape of an elbow winding machine includes a rotary disk 1, a belt feed wheel 2, a driven wheel 3, and a heating device 4; The round hole of the belt feeding wheel 2 is fixedly arranged in the circumferential direction of the rotary disk 1, and is arranged evenly at equal intervals, and the driven wheel 3 is fixedly arranged in the middle of the belt sending wheel 2 in a cross direction; the heating device 4 is fixedly arranged on the rotary disk 1, The heating device 4 is located at the bottom of the belt feeding wheel 2 on the rear of the rotary disk 1, the tension control device 5 is fixedly arranged on the top of the heating device 4, and the tension control device 5 is fixedly connected with the left end of the belt feeding whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com