Buffer type undercarriage for unmanned helicopter

A technology for unmanned helicopters and landing gear, which is applied to landing gear, aircraft parts, sleds/sleds, etc. It can solve the problems of reducing aerodynamic resistance, reducing life, and large force on the frame, so as to avoid occlusion and reduce aerodynamic resistance , to solve the effect of greater force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

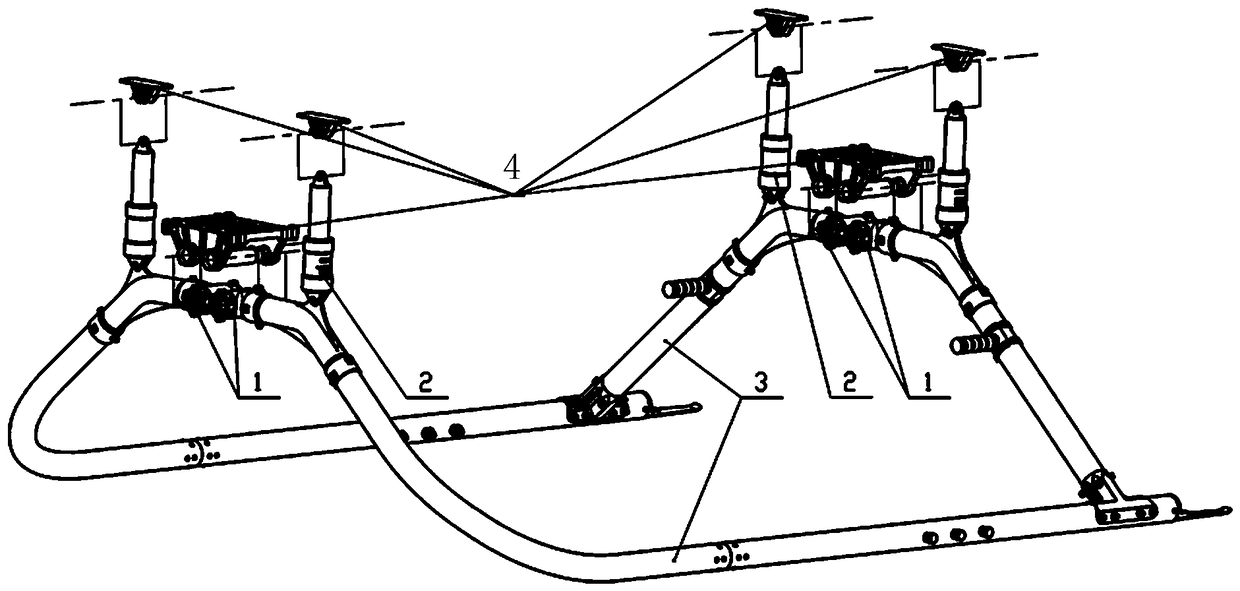

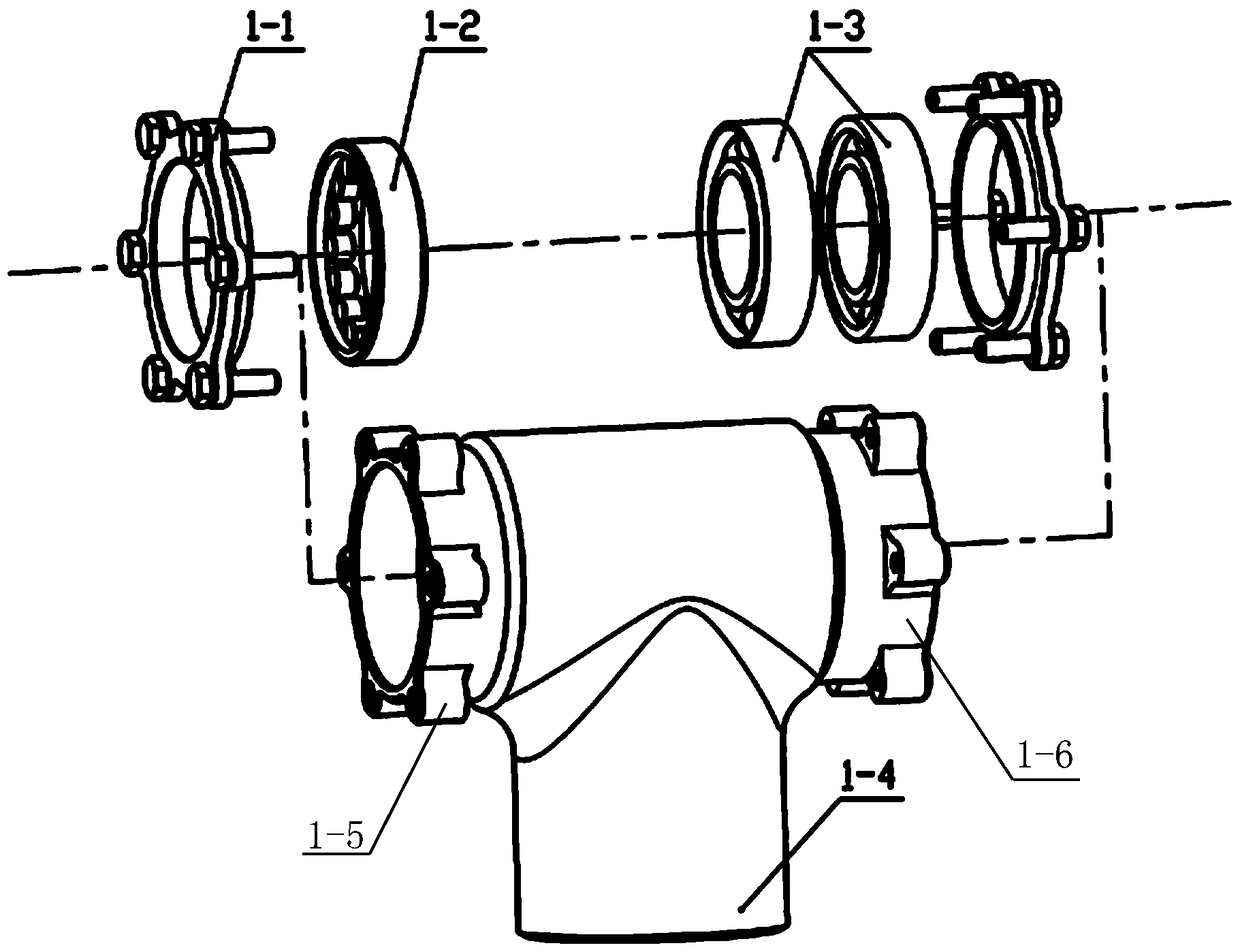

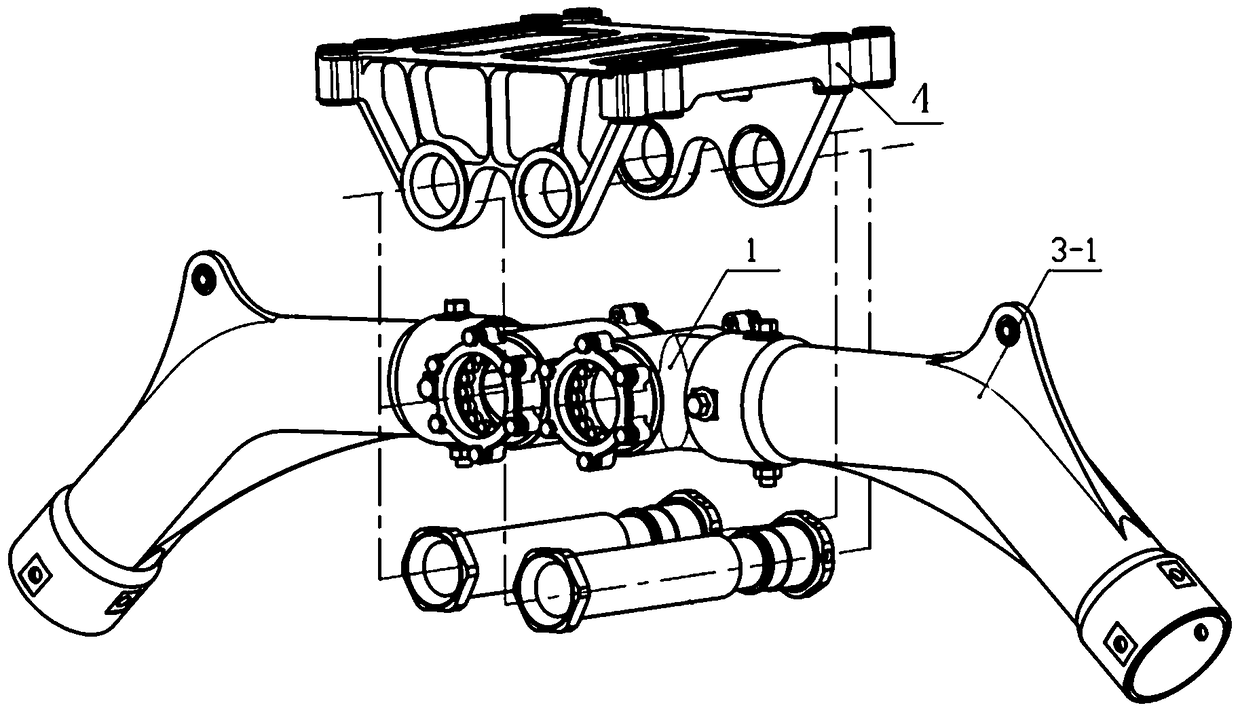

[0038] The cushioning landing gear of the present invention is as Figure 1-Figure 4 As shown, when the helicopter lands, the one-sided landing gear will rotate around the axis A1-B1, so the angle formed by the triangle sideline A1-A2 (B1-B2) and A1-A3 (B1-B3) will change, so the sideline The length of A2-A3 (B2-B3) changes, that is, the shock absorber is compressed so that the shock absorber compresses and consumes part of the energy; at the same time, because the landing gear rotates around the axis A1-B1, C1-C2 (connected to the ground) produces a direction The relative motion of the outside produces friction and consumes part of the energy. When the speed of the whole machine drops to zero, the landing gear system will form a movement opposite to the above process again, so that all the landing energy of the unmanned helicopter will be completely dissipated by the friction force generated by the buffer and the skid. The landing impact load is reduced, and the damage to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com