Bridge falling prevention device applied to buffering type steel strand stayed cable bridges and mounting method thereof

A cable-type, anti-drop beam technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of cable stress concentration, energy-absorbing tube damage, and support plate scratching, etc., to achieve good buffering effect and convenient construction. , to avoid the effect of scratching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

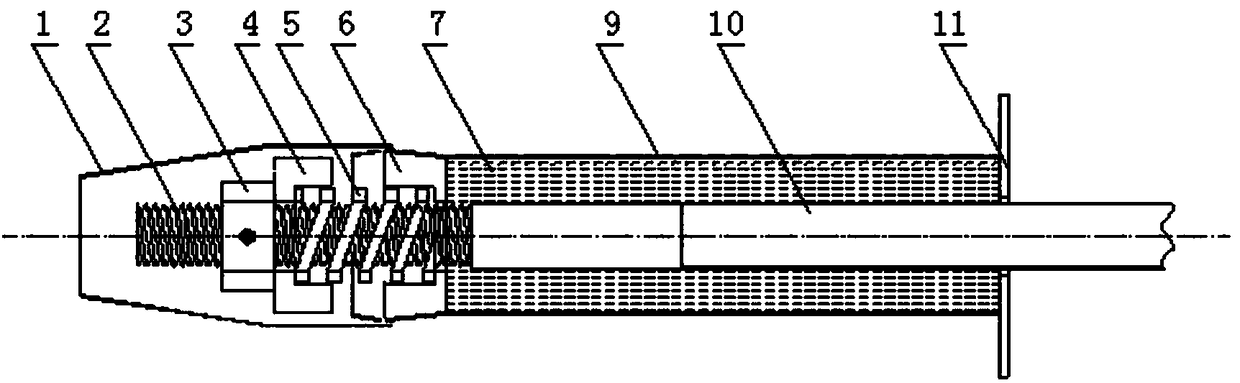

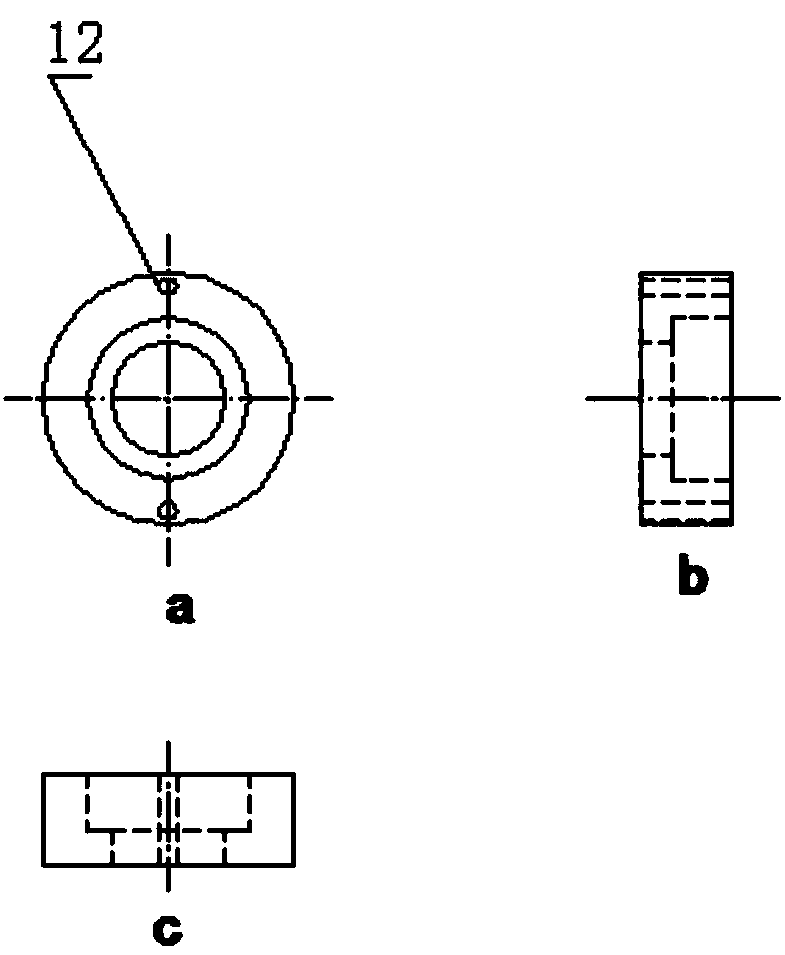

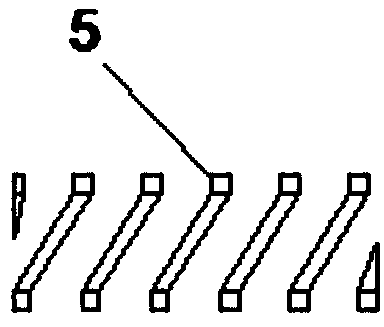

[0054] A buffer type steel strand cable type anti-drop beam device, such as figure 2 As shown, it includes a connection part, the connection part includes a pressure bearing plate 11 and a cable 10, one end of the cable 10 is connected with an anchor 2, the pressure bearing plate 11 is provided with a reserved hole, and the pressure bearing plate One side of 11 is provided with a shock-absorbing tube 9, and the other end of the shock-absorbing tube 9 is connected with a wedge-shaped backing ring 6 by pressing, and the inside of the shock-absorbing tube 9 is filled with a foaming agent composition 7, and the drag cable 10 passes through The reserved hole on the pressure bearing plate 11 and the foaming agent composition 7 are set, and one end connected to the anchorage 2 extends out of the foaming agent composition 7; the wedge-shaped washer ring 6 is sleeved on the anchorage 2, and the A support plate 4, a spring 5 and a nut 3 are also sleeved, and the two ends of the spring ...

Embodiment 2

[0070] Wherein, the foaming agent composition 7 is a rubber foaming material, comprising the following components in parts by weight: 100 parts of sulfur-modified neoprene rubber, 50 parts of filler, 30 parts of reinforcing agent, 5 parts of softening agent, 2 parts of oxidizing agent, 3 parts of stearic acid, 2 parts of polyethylene, 3 parts of hydrazine diphenylsulfate, 5 parts of zinc oxide, 0.2 parts of ethylene thiourea, and 1.5 parts of sulfur.

[0071] The filler is calcium carbonate, the reinforcing agent is carbon black, the softener is paraffin oil, and the antioxidant is KY445.

[0072] All the other structures and installation steps are the same as in Embodiment 1.

Embodiment 3

[0074] Wherein, the foaming agent composition 7 is a rubber foaming material, comprising the following components in parts by weight: 100 parts of sulfur-modified neoprene rubber, 60 parts of filler, 20 parts of reinforcing agent, 10 parts of softening agent, 1 part of oxidizing agent, 5 parts of stearic acid, 1 part of polyethylene, 15 parts of hydrazine diphenylsulfate, 3 parts of zinc oxide, 0.5 part of ethylene thiourea, and 0.5 part of sulfur.

[0075] The filler is calcium carbonate, the reinforcing agent is carbon black, the softener is paraffin oil, and the antioxidant is KY445.

[0076] All the other structures and installation steps are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com