Particle damper with optimized materials

A particle damper and damper technology, which is applied in the direction of building types, buildings, building components, etc., can solve problems such as high contact force, high acceleration, and large noise of particle dampers, so as to improve efficiency, increase life, and reduce noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

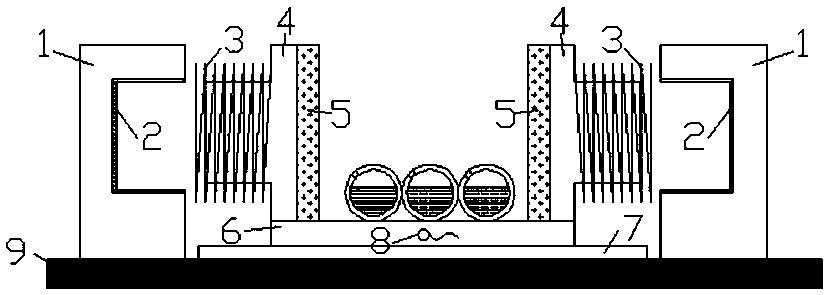

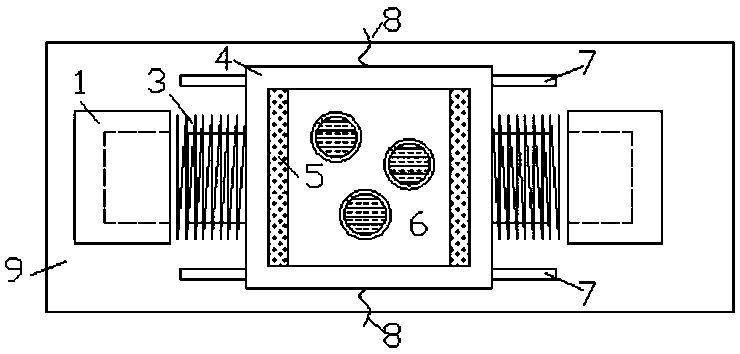

[0020] Embodiment 1: as figure 1 As shown, an embodiment of a particle damper using optimized materials in the present invention mainly includes a baffle plate 1 with a circular groove, a viscous liquid 2, a spring 3, a damper cavity wall 4, a soft Polyurethane foam plastic 5, copper plate 6, guide rail 7, wire 8, magnet 9, hollow ball 10 with holes, rubber 11 and water 12.

[0021] The damper cavity wall 4 is made of non-conductive material such as plastic, and is connected with the lower copper plate 6 by glue or nails. Lubricating oil is coated between the copper plate 6 and the guide rail 7, so that the coefficient of sliding friction between the two is small.

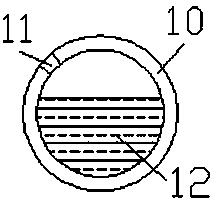

[0022] Such as figure 2 As shown, the granules are composed of hollow spherical balls 10 with holes, rubber 11 and water 12, the rubber 11 is plugged in the holes of the hollow spherical balls 10, and the interior of the hollow spherical balls 10 is filled with water 12. The hollow ball 10 is made of steel with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com