Method for improving oil recovery ratio by water injection with small pressure difference at multiple distribution points

A technology of recovery factor and pressure difference, applied in the field of improving the recovery rate of thick fault block reservoirs by using secondary bottom water, can solve the problems of improvement, unbalanced injection-production streamline, unbalanced water flooding and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

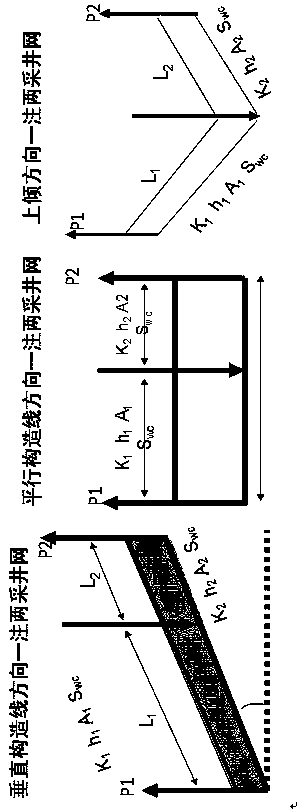

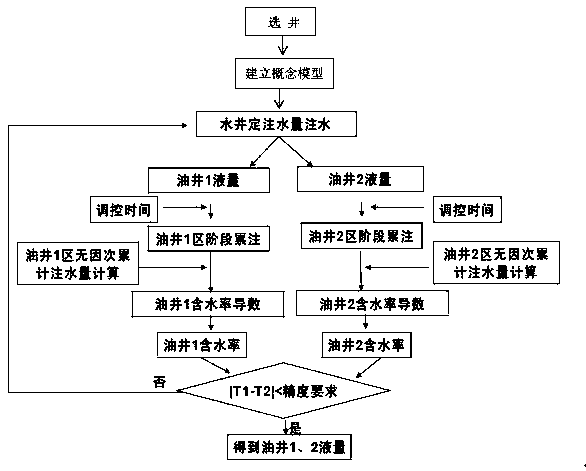

Method used

Image

Examples

Embodiment 1

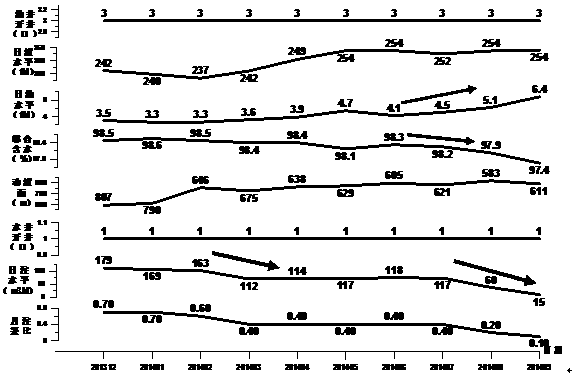

[0211] There are 1 water well and 3 oil wells in the He 50-Xie 16 well group. The water wells are generally injected with water, and the vertical water absorption is uneven. The layer with a relatively high water absorption corresponds to a higher oil well fluid volume of 168 tons / day, a water cut of up to 99.1%, and a relatively low water absorption. The layer corresponds to a low well fluid volume (37.1 tons / day), and a dynamic fluid level of 977 meters. Aiming at the above problems, a water injection test with small pressure difference at multiple distribution points was carried out. Increase the frequency of unstable adjustments, and gradually refine the betting into a pattern of 150-100-50-20 squares. After the implementation, corresponding to 3 oil wells, the comprehensive water cut decreased by 1.1 percentage points, the daily oil increase was 2.9 tons / day, and the formation energy remained stable. Such as image 3 shown.

Embodiment 2

[0213] There are 4 oil wells and 4 water wells in the He 3-Sideline 19 well group. This well group belongs to the north block of He 3. Due to the influence of formation dip angle and physical properties, water flooding and water channeling have occurred many times in history. To solve this problem, we For the joint allocation of water wells in the well group, the allocation is gradually reduced according to the energy recovery of the oil wells. For oil wells with better energy recovery, adjust ginseng to extract fluid; for water wells with poor energy recovery, reduce ginseng to control fluid. According to the production situation of the oil well, the injection and production parameters of the oil and water wells are periodically adjusted. After the implementation, the daily oil increase of the well group is 3.3 tons / day, the water cut is reduced by 2 percentage points, and the validity period is 4 months. Such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com