Current vortex sensor prepared from iron cobalt vanadium alloy

An eddy current sensor, iron-cobalt-vanadium alloy technology, applied in instruments, scientific instruments, material analysis through electromagnetic means, etc., can solve the problems of weak output signal, inability to apply metal sheet and double sheet detection, poor precision, etc., to achieve Strong induction signal, good strength and toughness, low residual magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

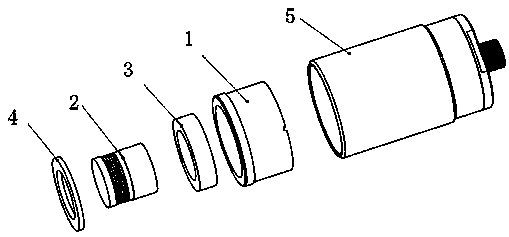

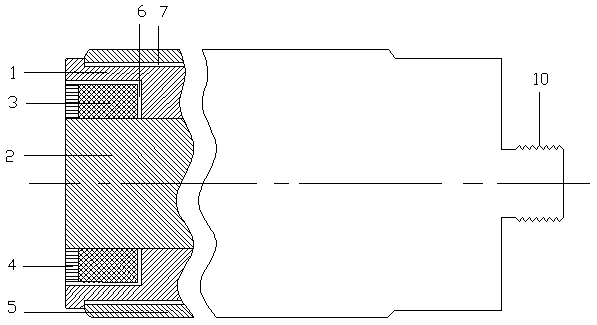

[0015] The eddy current sensor using iron-cobalt-vanadium alloy of the present invention comprises a housing 5, a sensor assembly arranged at one end of the housing 5, the sensor assembly includes an outer magnetic ring 1, an inner magnetic core 2 arranged inside the outer magnetic ring 1, a set The coil between the outer magnetic ring 1 and the inner magnetic core 2, the inner magnetic core 2 is made of iron cobalt vanadium alloy, the outer magnetic ring 1 is made of iron cobalt vanadium alloy, the inner magnetic core 2 is arranged inside the outer magnetic ring 1 and It is assembled with the outer magnetic ring 1. The induction magnetic core of the sensor is processed by iron-cobalt-vanadium alloy into an outer magnetic ring 1 and an inner magnetic core 2 and combined and assembled, a coil 3 is installed in the middle and the outside of the coil is fixed with a retaining ring 4 . The induction magnetic core of iron-cobalt-vanadium alloy is directly used as the external induc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com