Permanent magnet electromagnetic needle

An electromagnetic needle and permanent magnet technology, applied in the field of permanent magnet electromagnetic needle, can solve the problems of high comprehensive noise and inability to achieve full magnetic strength, and achieve the effects of reducing comprehensive noise, improving integrity, and solving the problem of wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

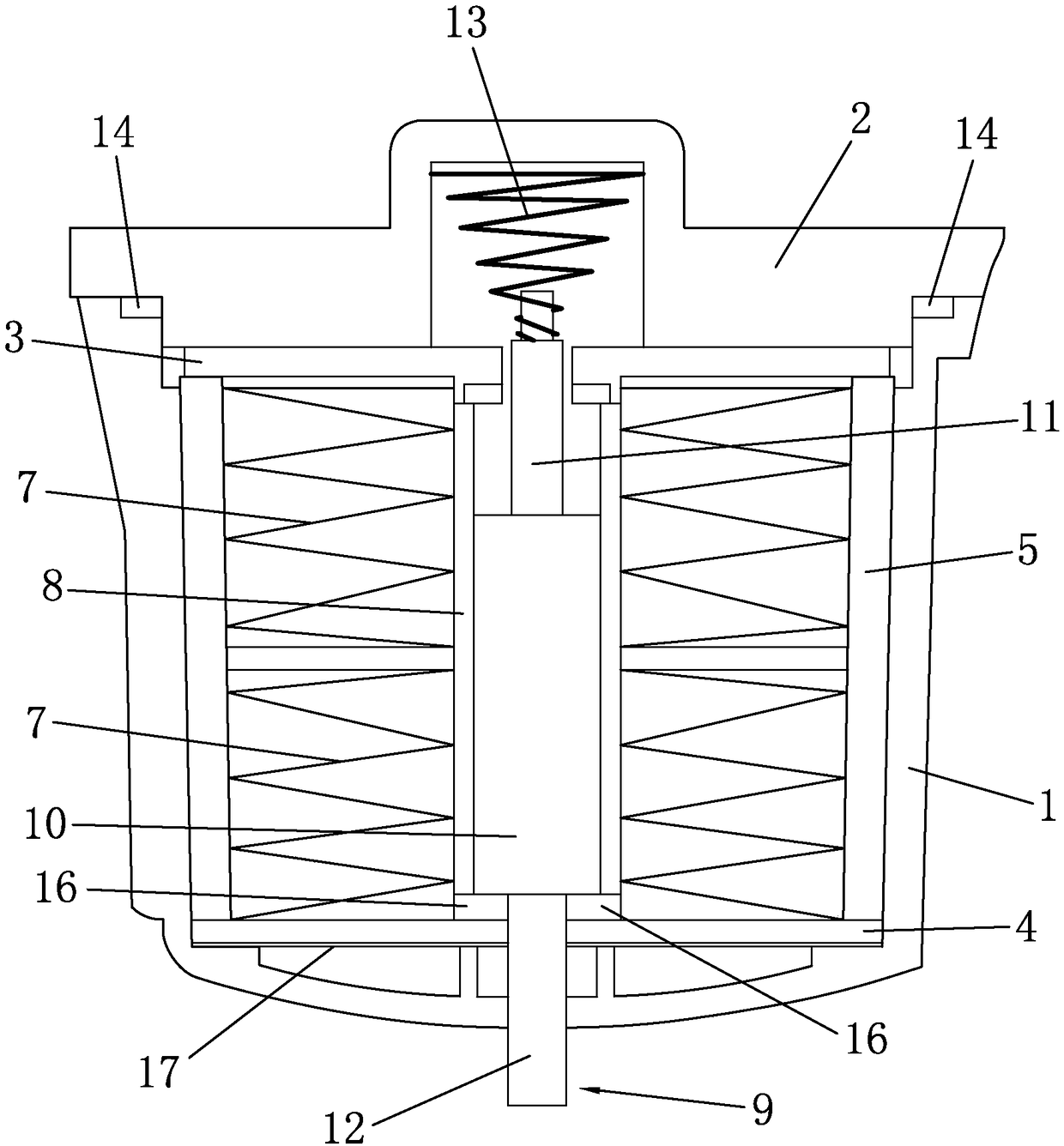

[0029] like Figure 1 to Figure 5 As shown, it is a permanent magnet electromagnetic needle of the present invention, which includes a casing 1 and an end cap 2, and the casing 1 and the end cap 2 are fixedly connected. Fixing bolts 14 are provided between the shell 1 and the end cover 2 to realize the fixed connection between the shell 1 and the end cover 2 , and facilitate the quick disassembly and assembly of the end cover 2 at the shell 1 .

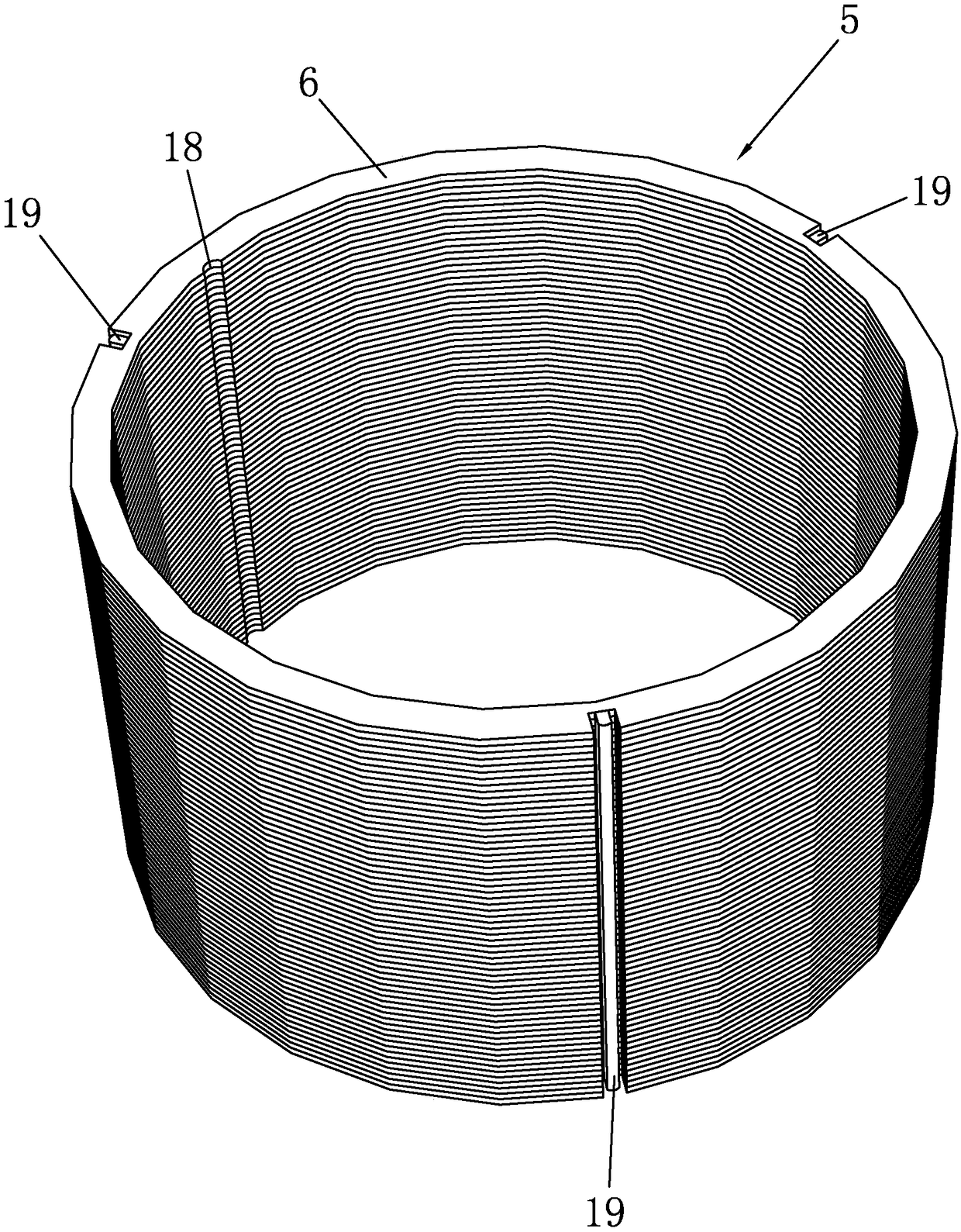

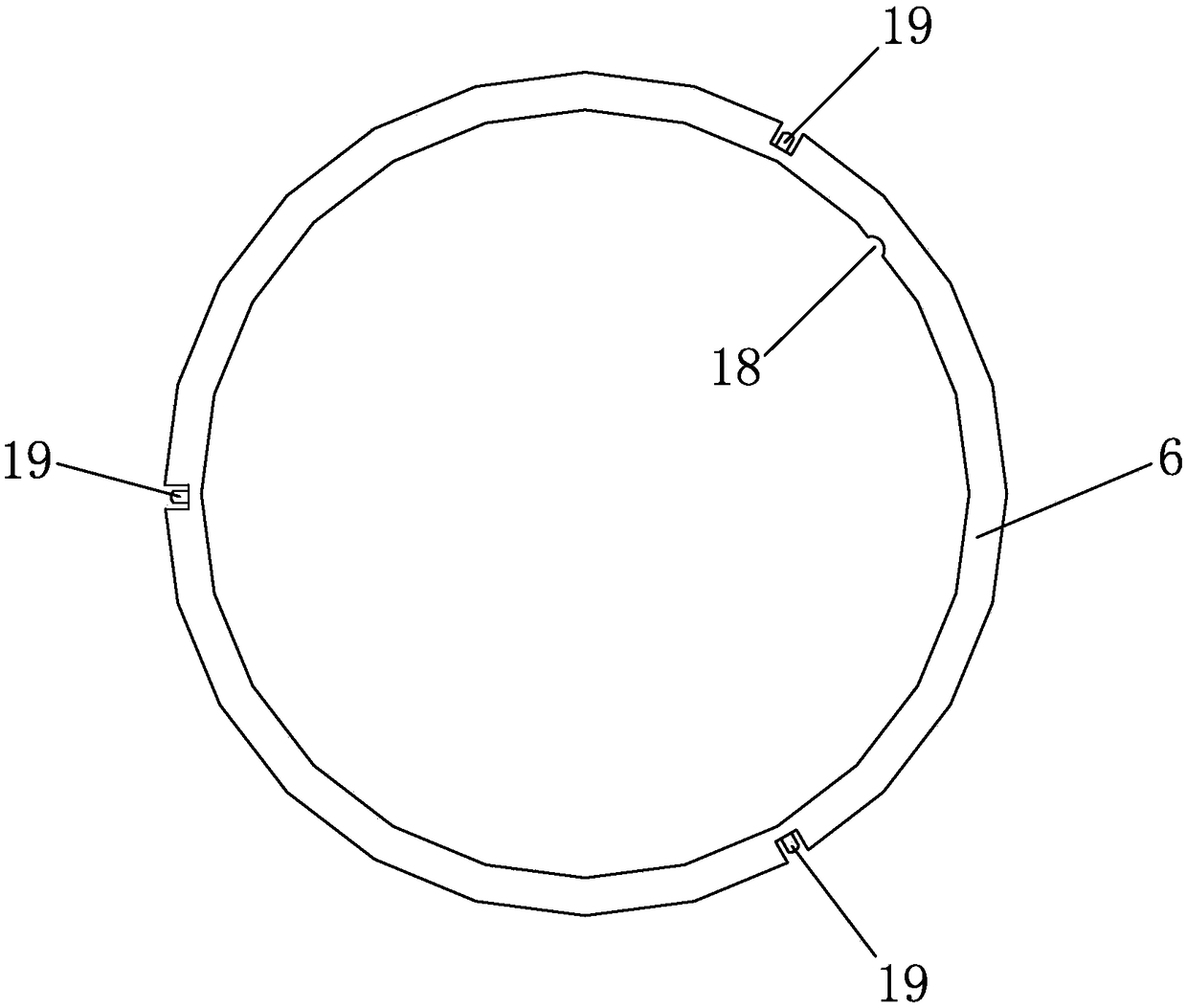

[0030] The top inside the shell 1 is provided with an upper positioning board seat 3 , the bottom inside the housing 1 is provided with a lower positioning board seat 4 , and a silicon steel sheet sleeve 5 is provided between the upper positioning board seat 3 and the lower positioning board seat 4 . The silicon steel sheet cover 5 includes a silicon steel sheet 6, which is longitudinally laminated and welded, which facilitates the manufacture of the silicon steel sheet cover 5 and controls the total height of the silicon steel sheet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com