A pump casing casting equipment

A technology for casting equipment and pump casings, applied in the field of casting equipment for pump casings, can solve the problems of uneven liquid, bubbles, difficult control of liquid flow, etc., and achieve good practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

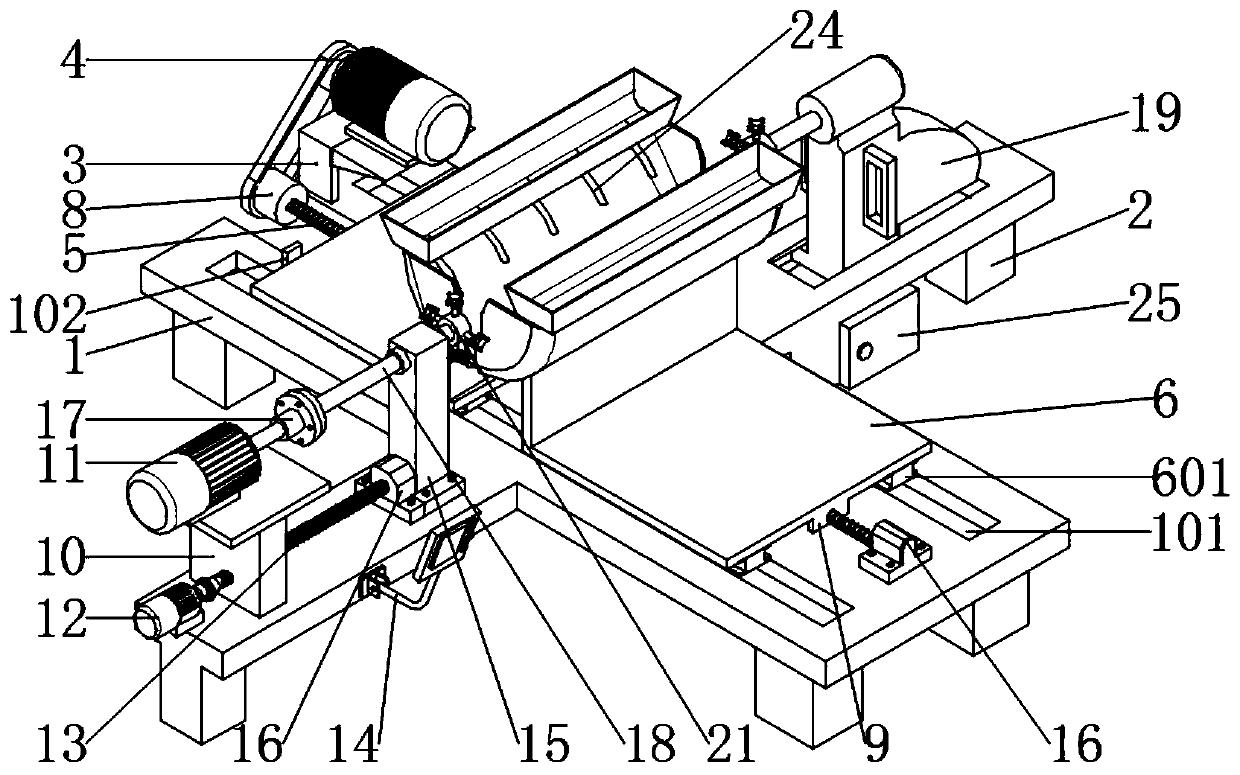

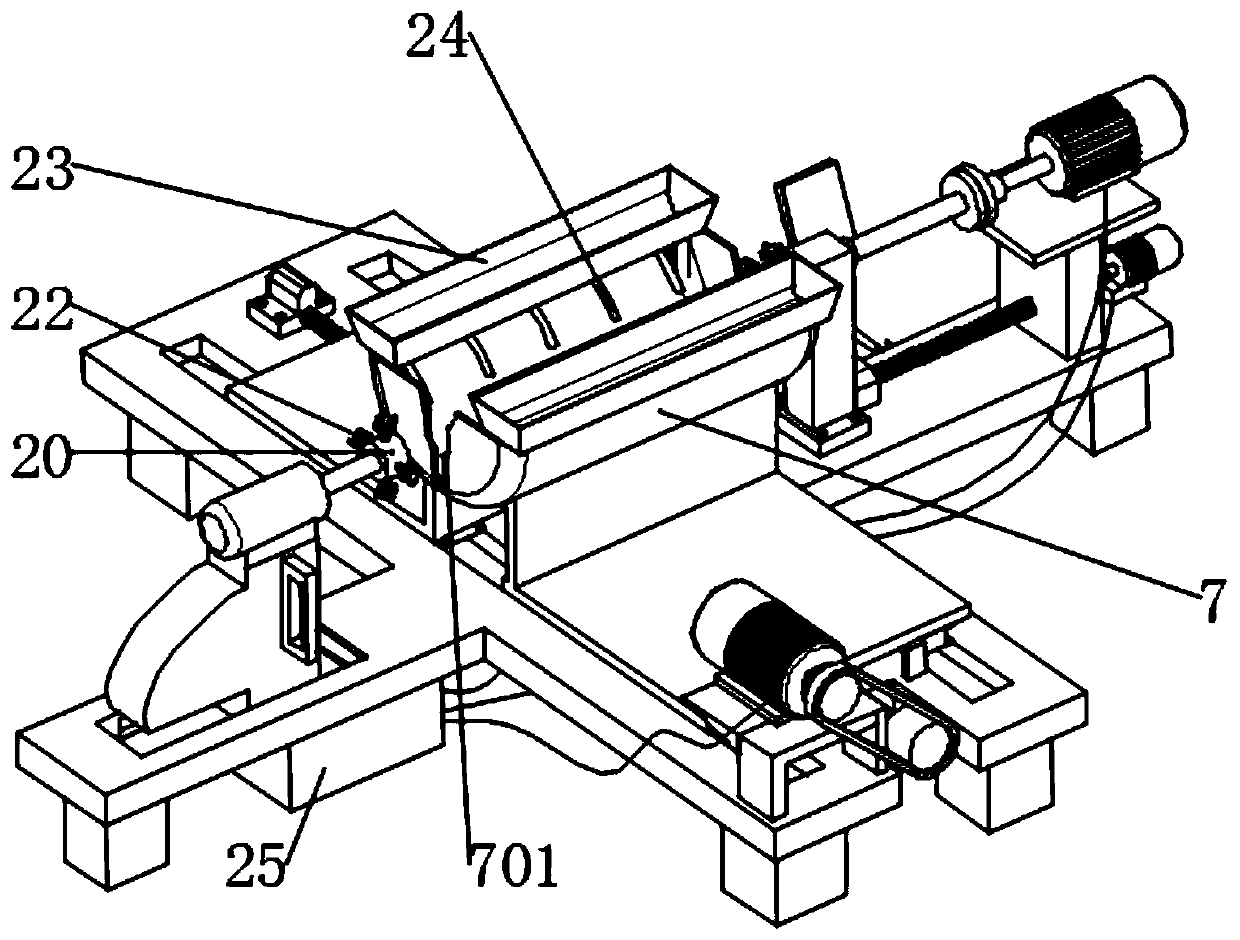

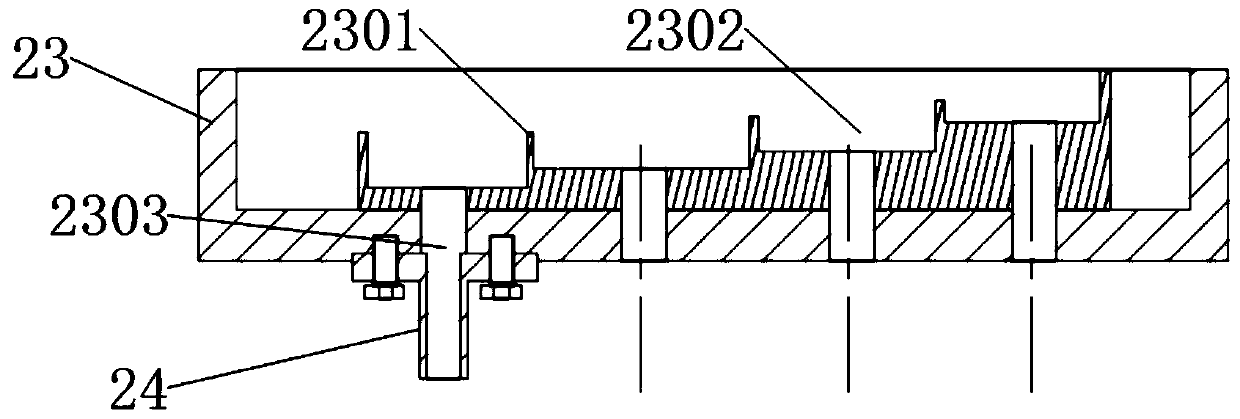

[0031] as attached figure 1 to attach Figure 8 Shown:

[0032]The present invention provides a pump casing casting equipment, including a bottom plate 1, a chute 101, a limit switch 102, a base 2, a first bracket 3, a first motor 4, a first screw rod 5, a sliding seat 6, and a slider 601, buckle seat 7, buckle groove 701, bottom surface section 702, pulley 8, screw rod connecting seat 9, second bracket 10, second motor 11, third motor 12, second screw rod 13, operation panel 14, Guide frame 15, bearing housing 16, coupling 17, rotating shaft 18, tailstock 19, first jacket 20, second jacket 21, locking bolt 22, hopper 23, partition plate 2301, small chamber 2302 , leakage hole 2303, material guide pipe 24 and electrical cabinet 25; the base plate 1 is a cross structure, and a base 2 for supporting the ground is installed at the four ends of the bottom surface, and a base plate 2 is set on the top surface of the base plate 1 in the left and right direction. There are two sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com