Press filtering device provided with core filtering unit inside

A filtering unit, pressing and filtering technology, which is applied in the direction of extracting juice from sugar cane, producing fat, dewatering/drying/concentrating sludge treatment, etc., can solve the problems of low pressing pressure and low liquid yield, etc., to reduce loss and save money Covering area and avoiding the effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] Detailed technical scheme of the present invention:

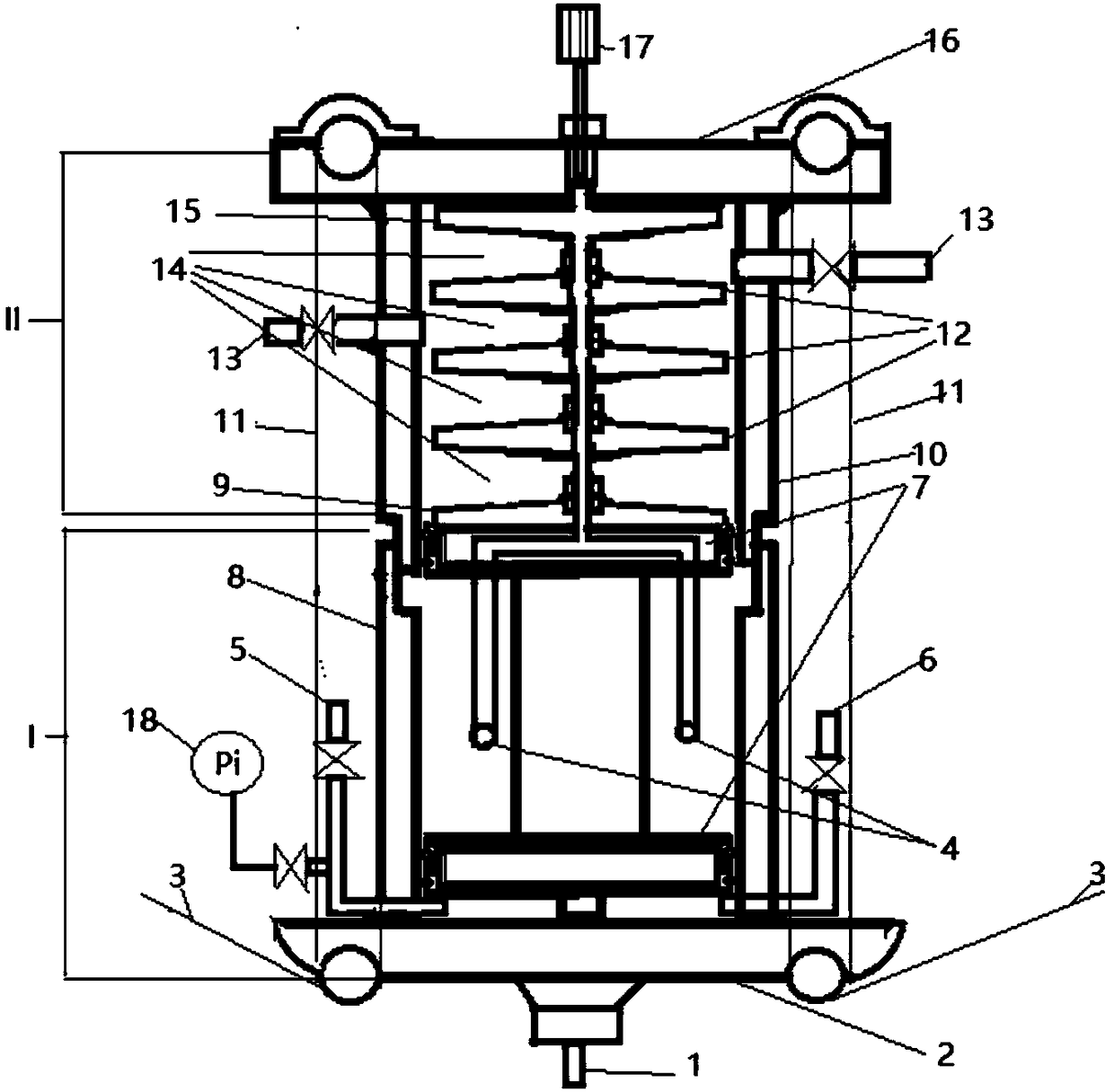

[0016] The device of the present invention comprises a pressing filter part II and a pressing part I.

[0017] 1. The press filter component includes a built-in filter unit (the filter unit shown in the figure is a press filter disc 9, 12, 15 with a filter hole design and a press filter function) and a pressure-bearing cylinder 10. The filter unit and the pressure-bearing cylinder together constitute the cavity 14 for the squeezed material.

[0018] 2. The pressure-applying part consists of a built-in pressure-applying part (the pressure-applying part in the figure is a pressurizing piston 7) and a pressure-bearing cylinder 8. The pressure-applying part is combined with the pressure-bearing cylinder to form a pressure-applying liquid storage chamber.

[0019] 3. Open the feed valve 13 shown in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com