Porous solid granular slow release fertilizer

A porous solid and granular technology, applied in solid/semi-solid fertilizers, animal carcass fertilizers, nitrogen fertilizers, etc., can solve the problems of harmful, combustible and irritating to the body, achieve high utilization rate, high water absorption rate, and reduce irrigation times Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment relates to a porous solid granular slow-release fertilizer and a preparation method thereof;

[0053] Weigh the following raw materials in parts by weight in advance:

[0054] 48 parts of compound organic matter;

[0055] 11 parts of waxy cornstarch;

[0056] 8 parts of phosphated starch;

[0057] 4 parts of degradable cross-linking agent;

[0058] 2 parts carrageenan;

[0059] 5 parts of 40 mesh shell powder;

[0060] 1 part of palm fiber with a length of 600 μm;

[0061] 3.5 parts of 40 mesh palygorskite powder;

[0062] 1.5 parts of compound blowing agent;

[0063] 1 part of compound coupling agent;

[0064] 0.3 parts of trace elements;

[0065] 0.2 parts of mixed strains;

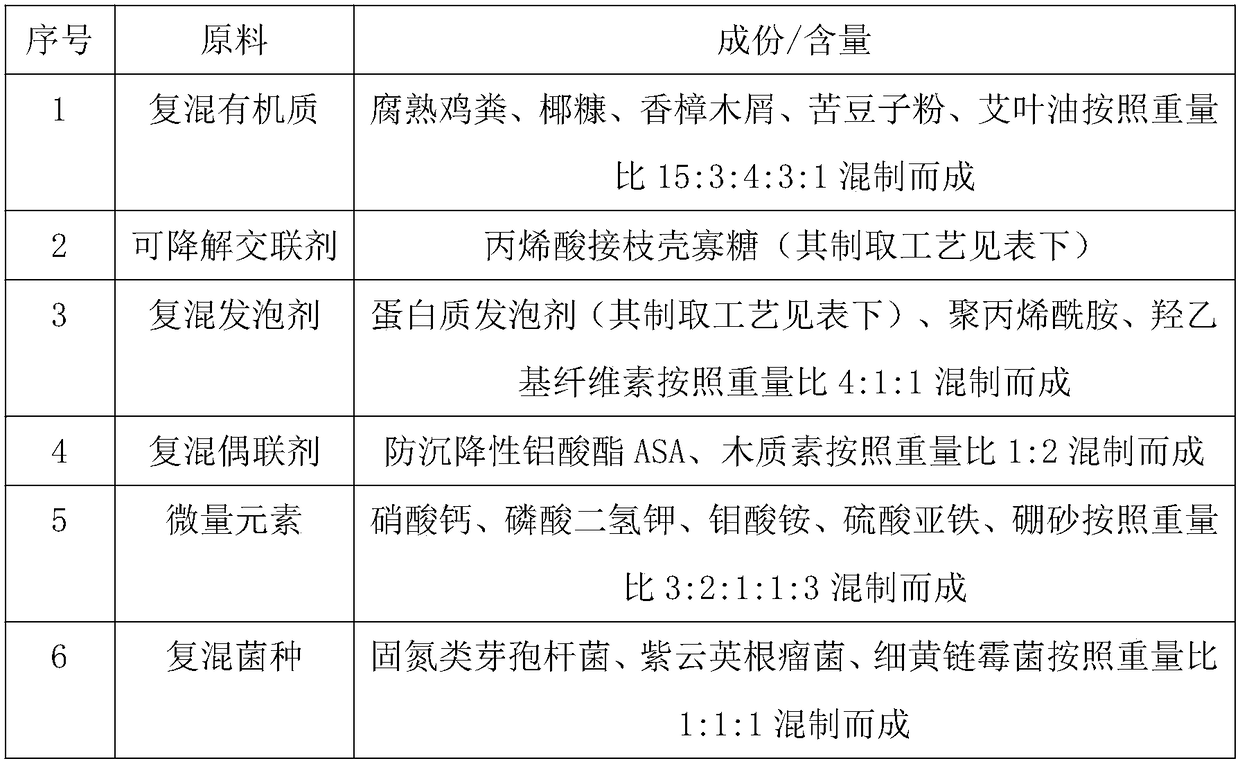

[0066] The preparation of the above-mentioned part of raw materials is selected as shown in the following table 1:

[0067] Table 1

[0068]

[0069] (1) protein foaming agent: get the ox hoof horn powder slag of 3 parts, the corn bran bran of 4 parts, the concentrati...

Embodiment 2

[0076] This embodiment relates to a porous solid granular slow-release fertilizer and a preparation method thereof;

[0077] Weigh the following raw materials in parts by weight in advance:

[0078] 50 parts of compound organic matter;

[0079] 12 parts waxy cornstarch;

[0080] 9 parts of phosphated starch;

[0081] 4.5 parts of degradable cross-linking agent;

[0082] Carrageenan 2.3 parts;

[0083] 5.5 parts of 45 mesh shell powder;

[0084] 1.2 parts of palm fiber with a length of 650 μm;

[0085] 4 parts of 45 mesh palygorskite powder;

[0086] 1.8 parts of compound blowing agent;

[0087] 1.2 parts of compound coupling agent;

[0088] 0.35 parts of trace elements;

[0089] 0.23 parts of mixed strains;

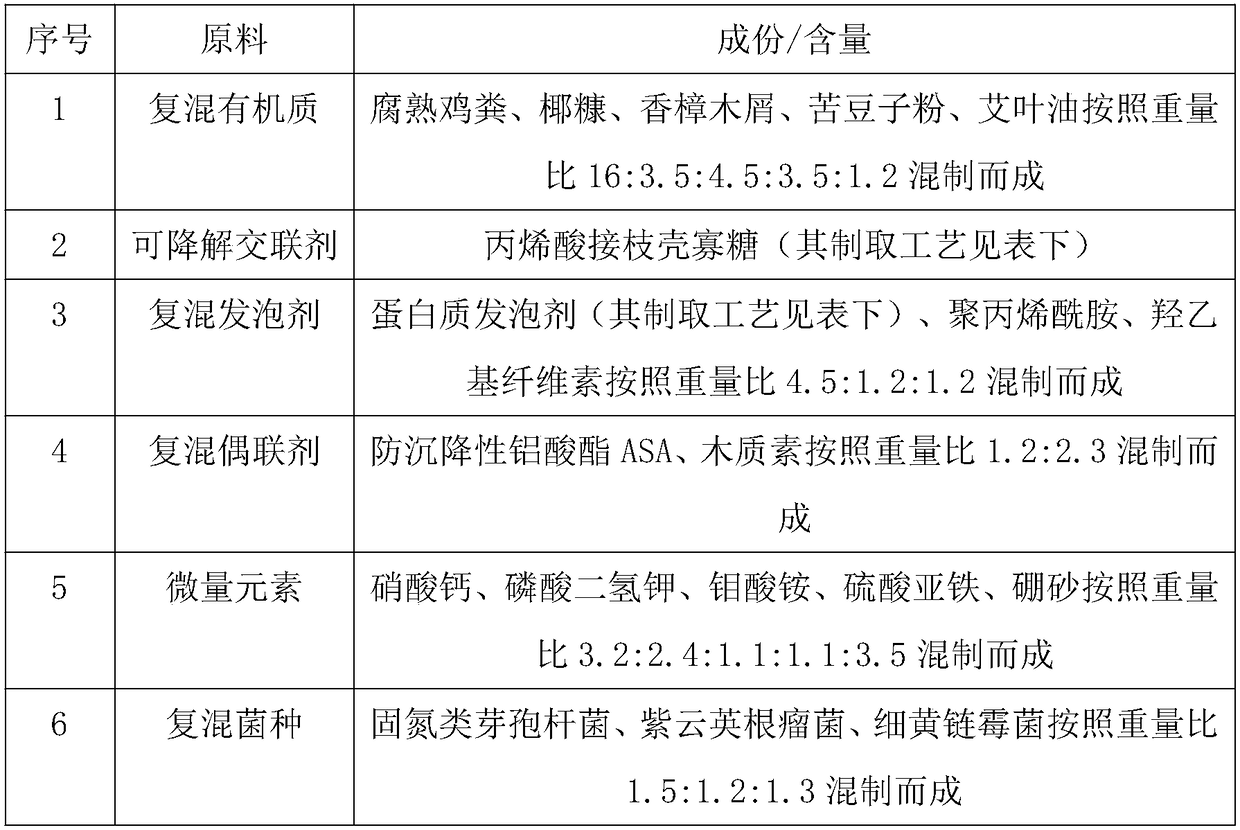

[0090] The preparation of above-mentioned part raw material is selected as shown in following table 2:

[0091] Table 2

[0092]

[0093] (1) protein foaming agent: get the ox hoof horn powder slag of 3.5 parts, the corn bran bran of 4.5 parts, the concentr...

Embodiment 3

[0100] This embodiment relates to a porous solid granular slow-release fertilizer and a preparation method thereof;

[0101] Weigh the following raw materials in parts by weight in advance:

[0102] 52 parts of compound organic matter;

[0103] 13 parts of waxy cornstarch;

[0104] 10 parts of phosphated starch;

[0105] 5 parts of degradable cross-linking agent;

[0106] Carrageenan 2.5 parts;

[0107] 6 parts of 40-60 mesh shell powder;

[0108] 1.5 parts of palm fiber with a length of 700 μm;

[0109] 4.5 parts of 40-60 mesh palygorskite powder;

[0110] 2 parts of compound foaming agent;

[0111] 1.5 parts of compound coupling agent;

[0112] 0.4 parts of trace elements;

[0113] 0.25 parts of mixed strains;

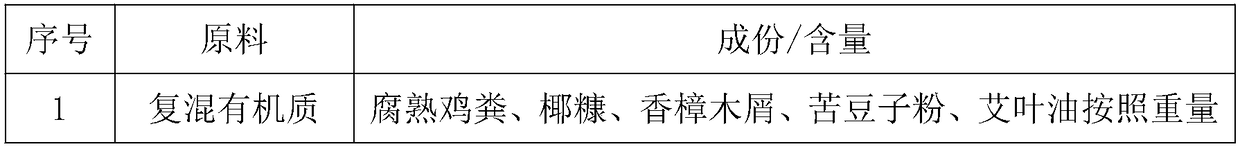

[0114] The preparation of the above-mentioned part of raw materials is selected as shown in the following table 3:

[0115] table 3

[0116]

[0117]

[0118] (1) protein foaming agent: get the ox hoof horn powder slag of 4 parts, the corn bran bran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com