Composite elasticity and damping shock resistance shock absorber of gas turbine device

A gas turbine and shock absorber technology, applied in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as insufficient shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

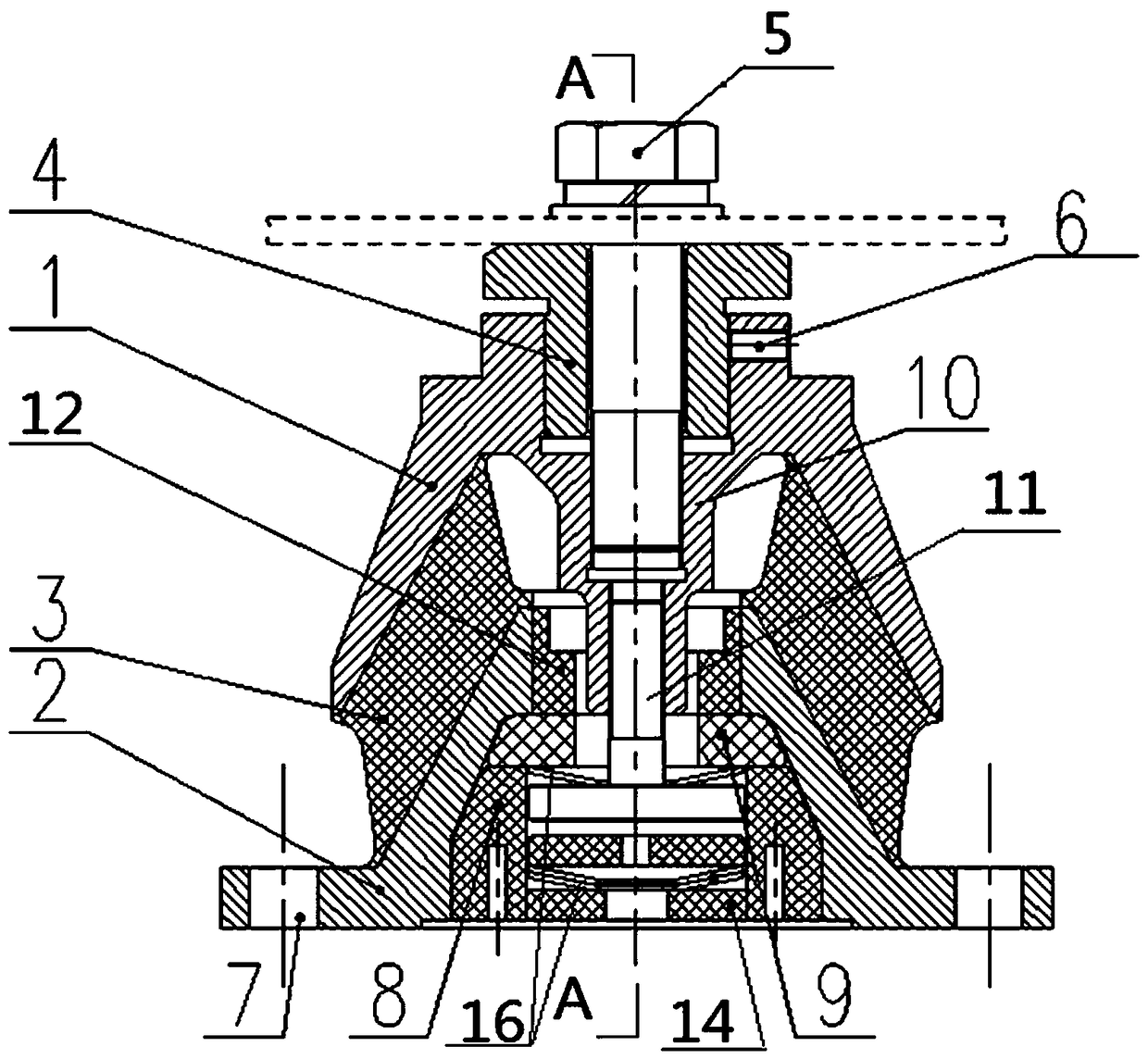

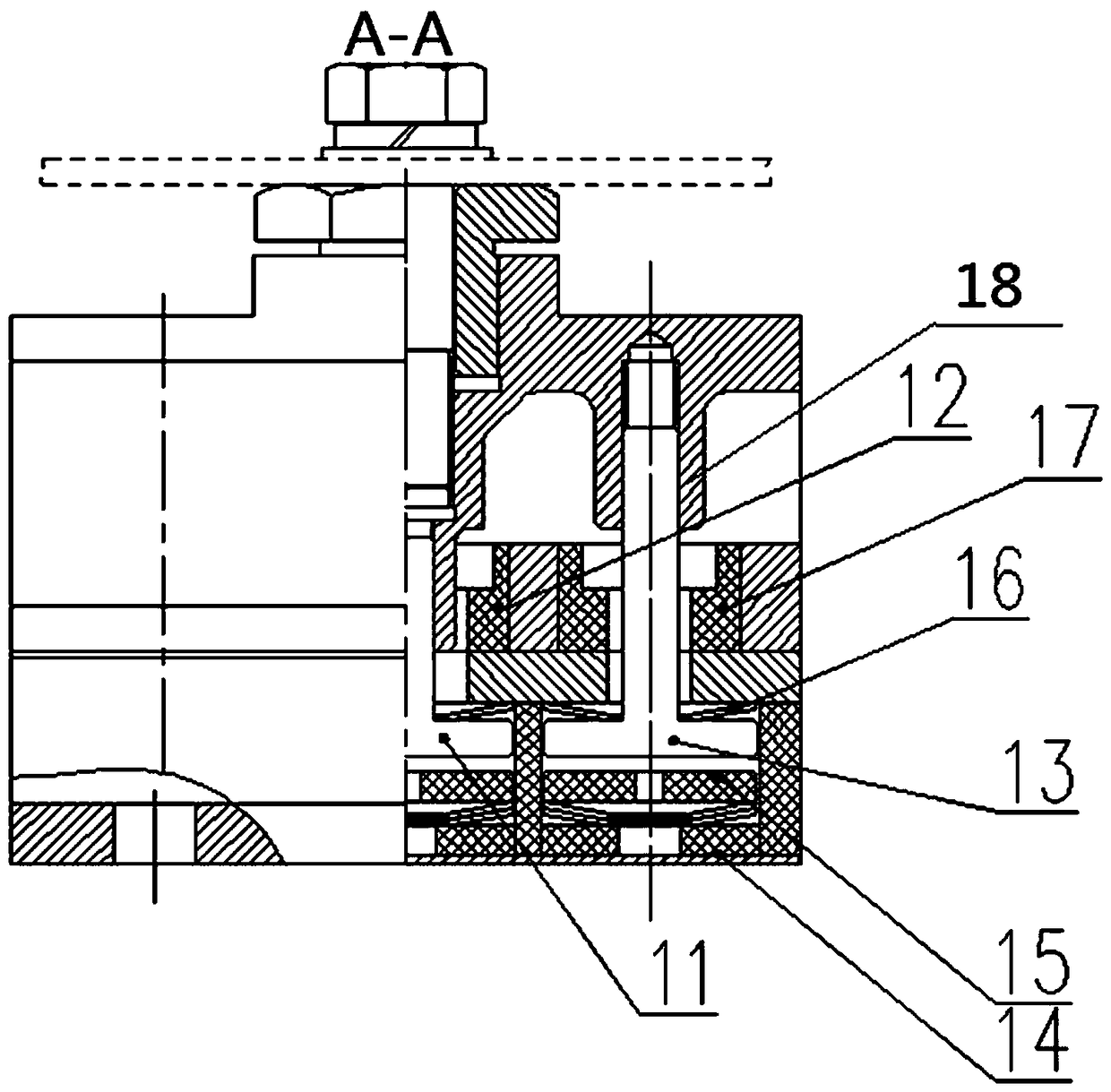

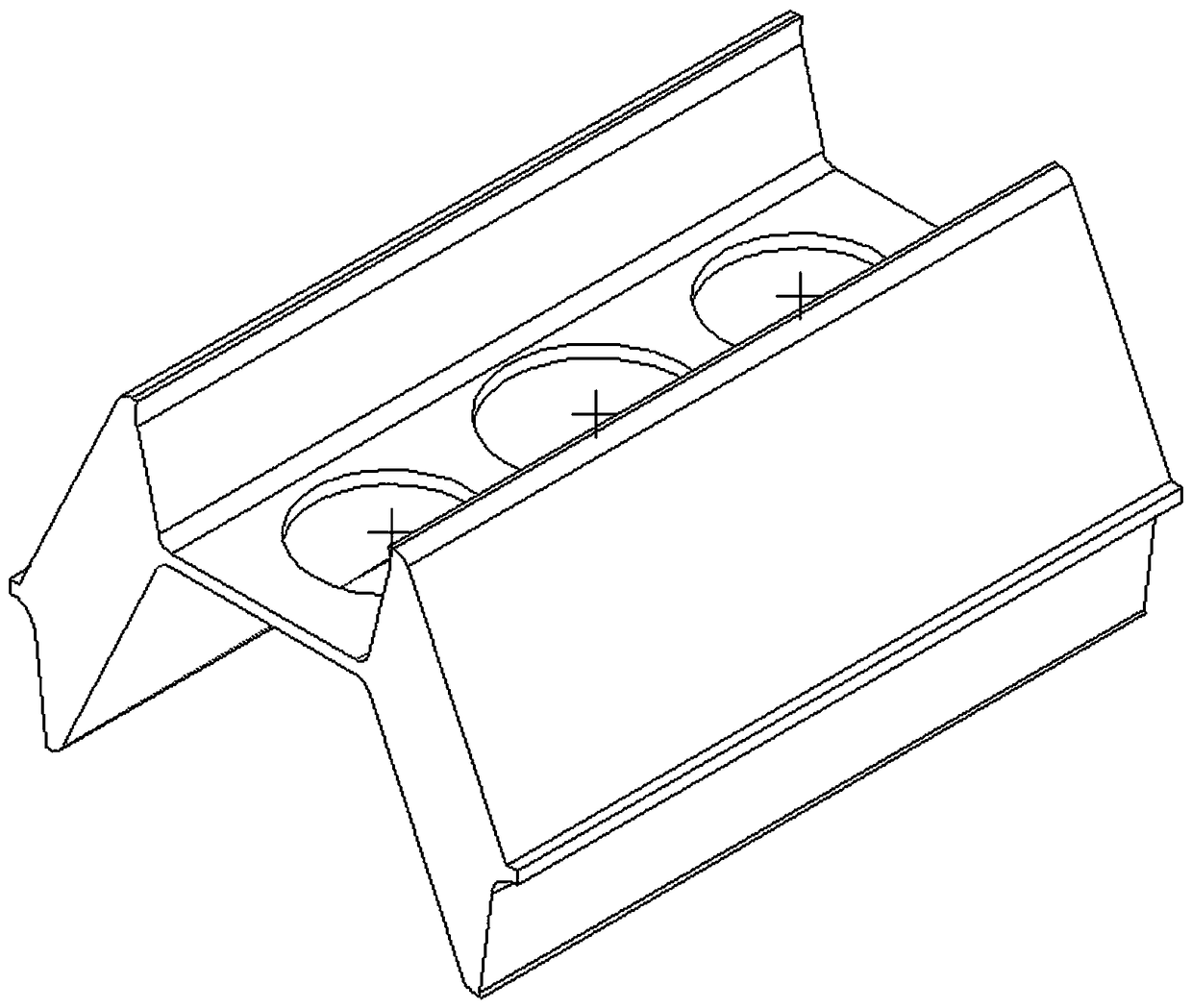

[0018] A composite elasticity and damping anti-shock shock absorber for a gas turbine device, including a mounting screw 5, a shock absorber upper cover 1, a shock absorber base 2, and a body vulcanized as a whole between the shock absorber upper cover 1 and the shock absorber base 2 Rubber 3, the above constitutes the basic external square structural features of the shock absorber, which is conducive to the design of different impact stiffnesses in the vertical, horizontal and longitudinal directions; the top of the shock absorber upper cover 1 is provided with a height adjustment nut 4, which is in the shock absorber The upper end surface of the hexagonal height adjustment nut 4 of the upper cover 1 is the installation surface of the gas turbine underframe, and the total height between the installation surface of the gas turbine underframe and the base panel of the hull is adjusted by rotation, and a stop lock is set on the side of the height adjustment nut 4 Tighten the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com