Equipment for burning household waste by brown gas

A technology of domestic waste and brown gas, applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve problems such as insufficient incineration, pollution of underground rivers, and large-scale occupation of land, so as to reduce space occupation and degradation time, and inhibit Production of dioxins and effects of efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

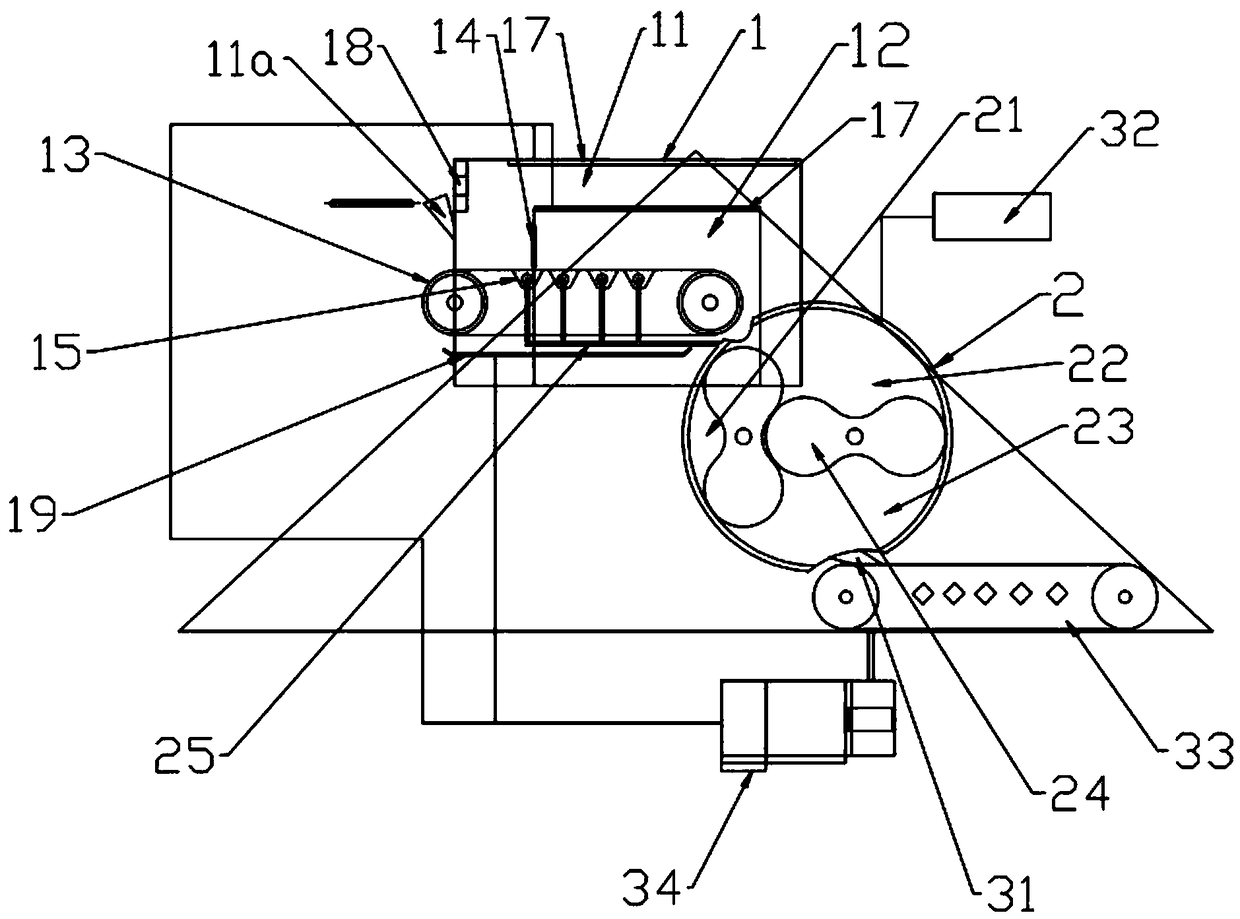

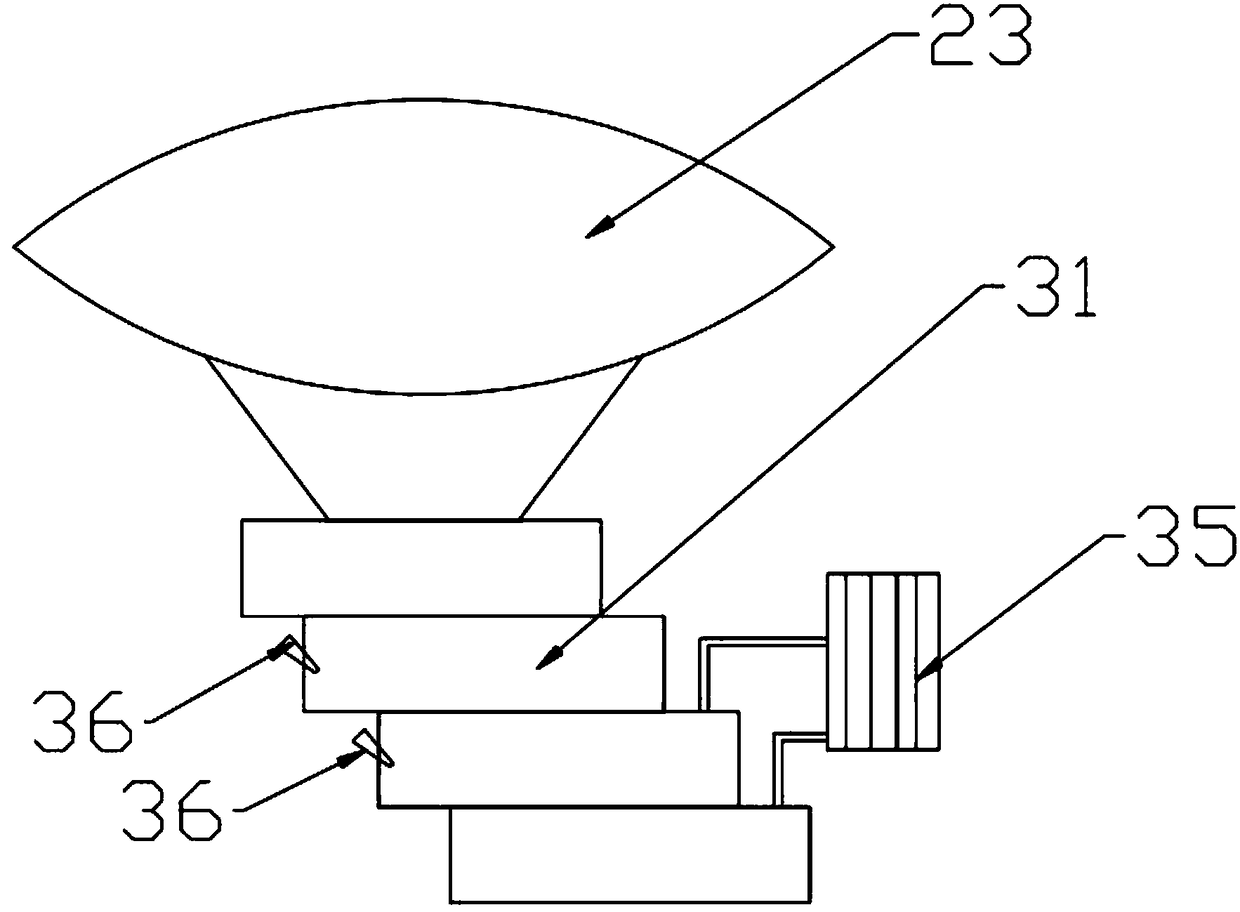

[0018] Embodiment 1: as figure 1 with image 3 As shown in the present invention, a kind of equipment that utilizes Brown gas to incinerate domestic waste includes a pretreatment chamber 1, an incineration chamber 2, and a recovery chamber 3. The pretreatment chamber 1 includes a feed chamber 11 and an air-drying chamber 12. The outer wall of the feed chamber 11 is provided with a feed port 11a, and the pretreatment chamber 1 is provided with a conveyor belt 13, and the conveyor belt 13 runs through the feed chamber 11 and the air-drying chamber 12, and the feed chamber 11 and An isolation plate 14 is arranged between the air-drying chambers 12 to isolate it, and the upper and lower surfaces of the conveyor belt have a plurality of through holes, and a plurality of air guide grooves 15 are arranged below the conveyor belt, and all the air guide grooves 15 communicates with the hot air pipe 16, the incineration chamber 2 is provided with a drum inner core 24 to divide it into ...

Embodiment 2

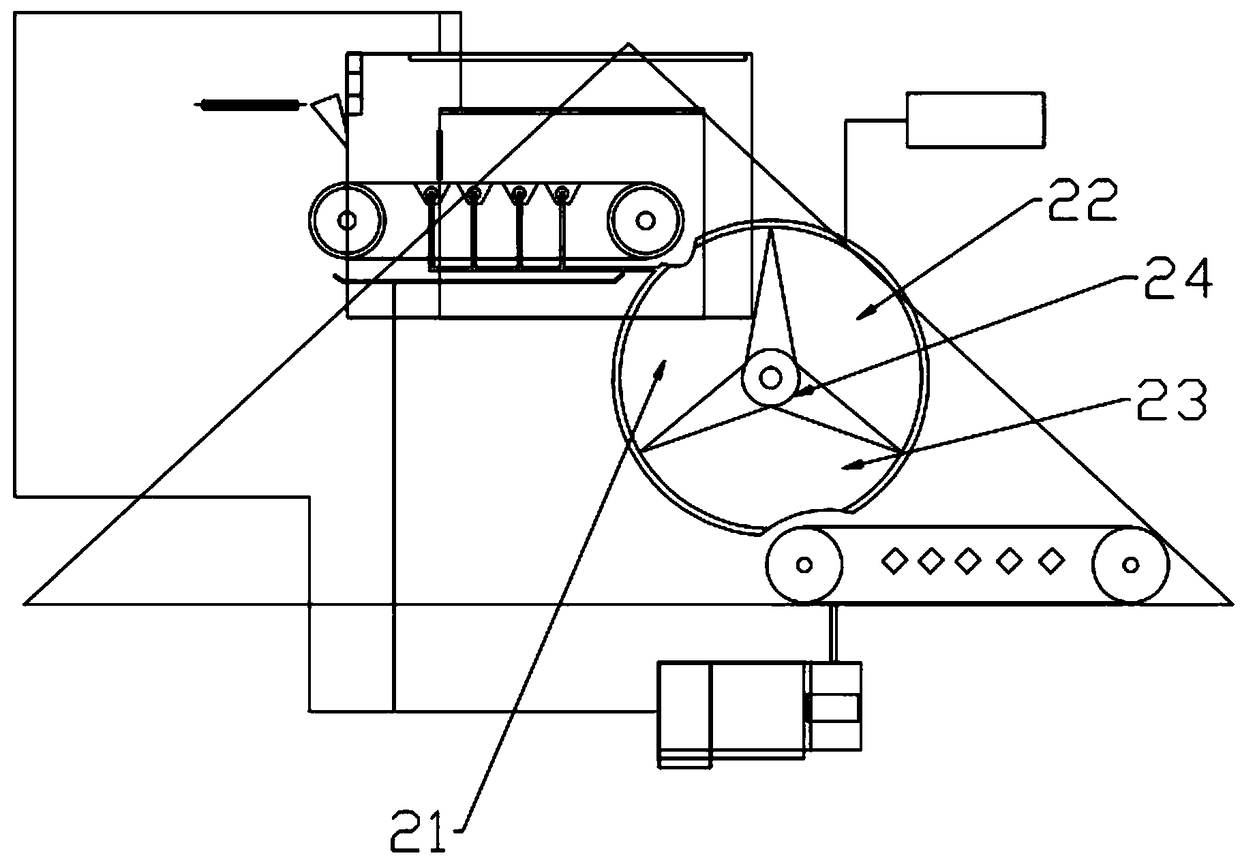

[0024] Example 2: Refer again figure 2 and image 3 The difference with Embodiment 1 is that the structure of the incineration chamber 2 is different. In the present embodiment, the inner core 24 of the drum is in the shape of a "Y", and the incineration chamber 2 is also divided into a first-level incineration chamber 21, two The first-stage incineration chamber 22 and the third-stage incineration chamber 23, and the drum inner core 24 are driven by a motor to rotate. The volume of the three incineration chambers is the same, and the rotation is more stable, which reduces the load on the equipment and reduces the cost of the equipment.

[0025] In the process of processing garbage, the present invention does not have the external filtration of smoke and water vapor, and the characteristics of Brown gas as a fuel can be high temperature, catalyzed, and inhibit the production of dioxins, so as to realize the rapid processing of a large amount of domestic garbage residues and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com