Brush bristle material, brush using same, and manufacturing method for said brush bristle material

A technology of brushes and sea islands, applied in the direction of bristles, brushes, applications, etc., can solve problems such as cracking and insufficient durability, and achieve the effect of excellent durability and excellent cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0064] Embodiment 1~10, comparative example 1, 2

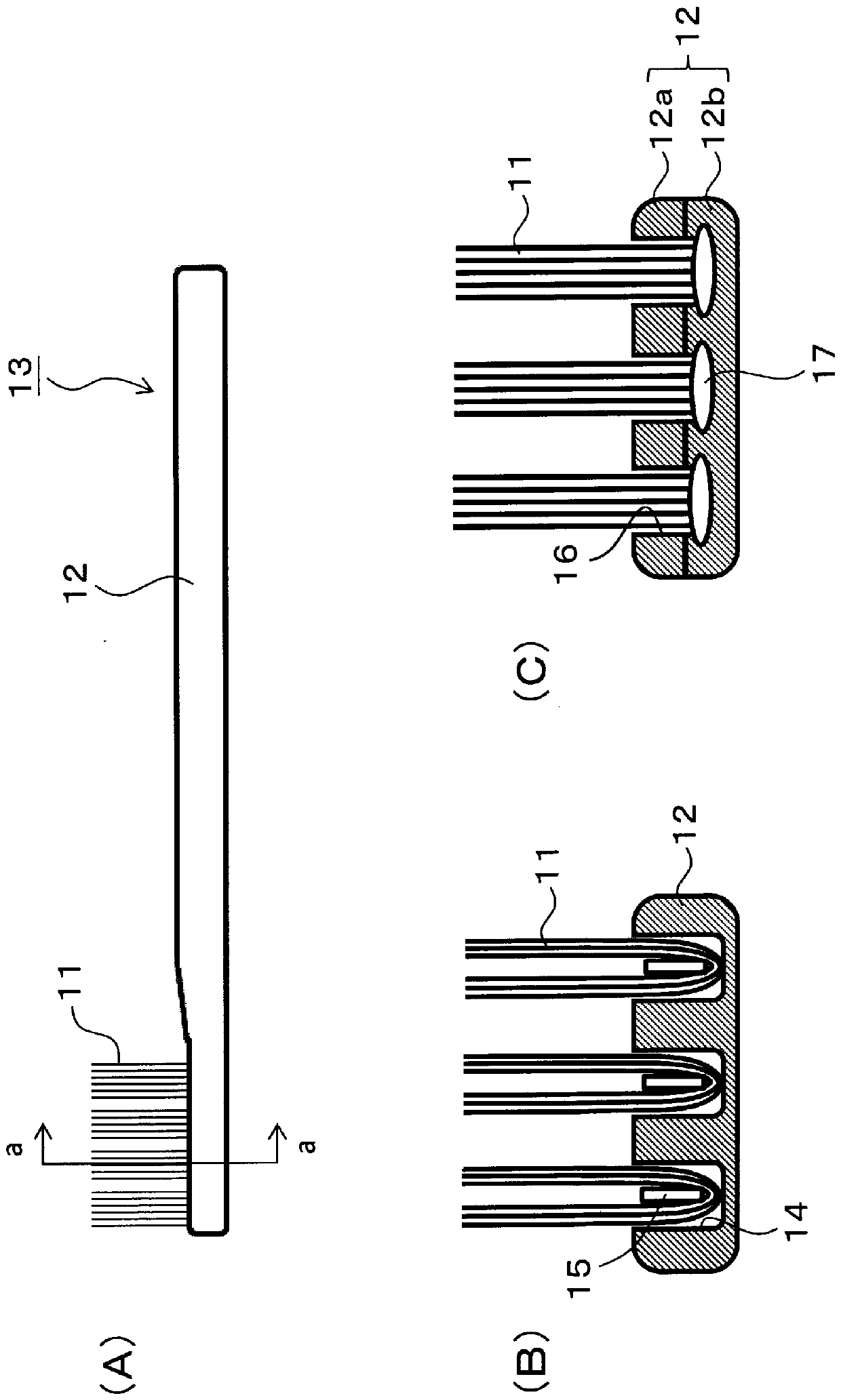

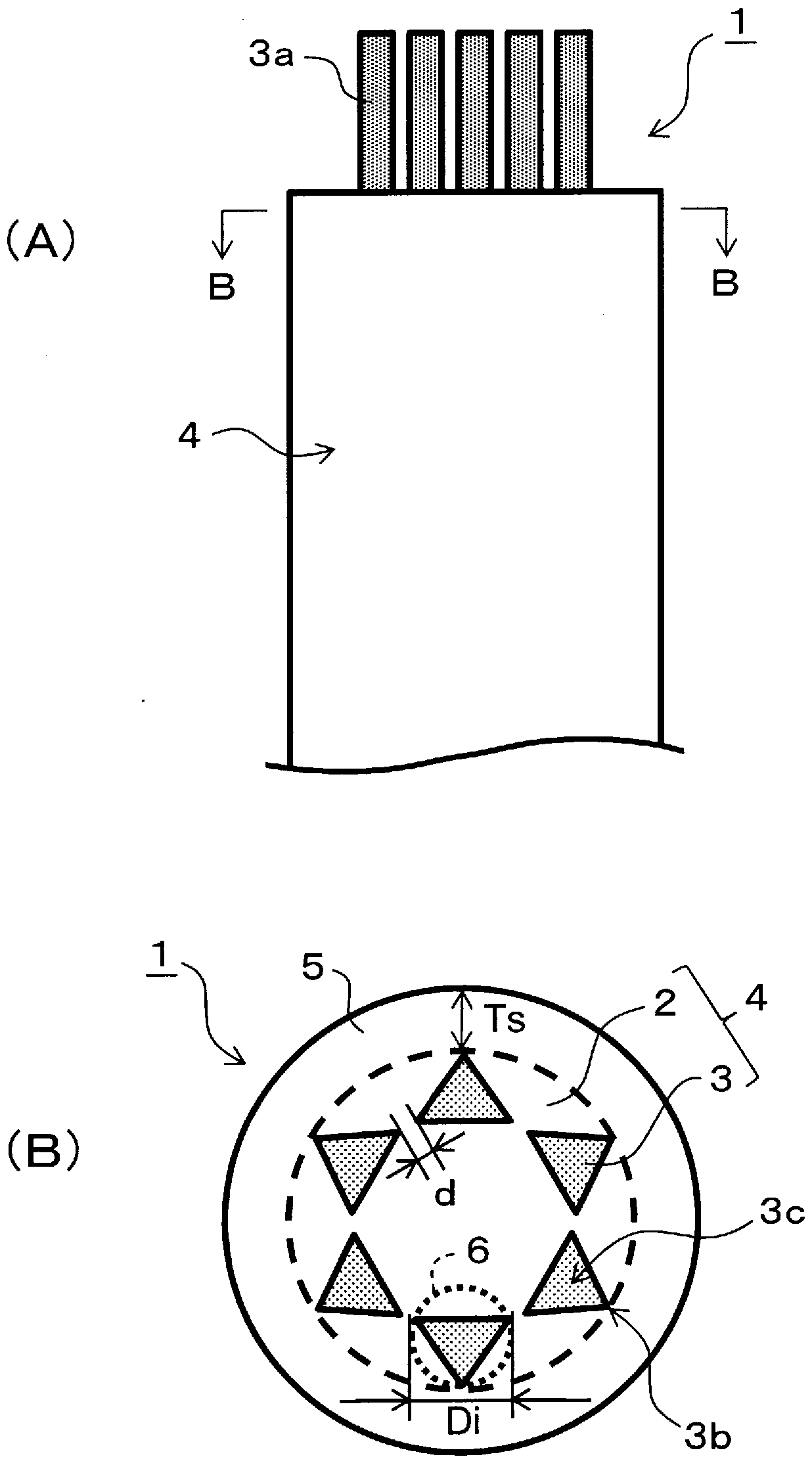

[0065] [Production of brush hair material]

[0066] As raw materials, polybutylene terephthalate (PBT, manufactured by Toray Co., Ltd., "Traycon" (registered trademark) 1100SW), polyethylene terephthalate ( PET, manufactured by Toray Co., Ltd., T755M), nylon 610 (Ny610, manufactured by Toray Co., Ltd., "Amiran" (registered trademark) CM2001), thermoplastic polyamide elastomer (Ny11-PTMG (polytetramethylene glycol), "Peback" (registered trademark) 72R53, manufactured by Alkema Co., Ltd., polybutylene naphthalate (PBN, manufactured by Toyobo Co., Ltd., AE-500). The resin types of the sea and islands, the area ratio of the sea and islands, and the number of islands were set as shown in Table 2, and the islands with fringes were designed so that they were more heavily present in the sea near the center. Sea-island composite fibers were melt spun. After cooling and solidifying the melt-sprayed fiber in water, stretch it to 4.5 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com