Ultraclean emission type ammonia-process desulfurization device and technology

An ammonia desulfurization and clean technology, applied in the field of flue gas purification, can solve the problems of lack of ammonia desulfurization process, difficult to popularize and apply on a large scale, limited application scenarios, etc., to achieve reasonable process settings, improve SO2 absorption efficiency, and reduce complexity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

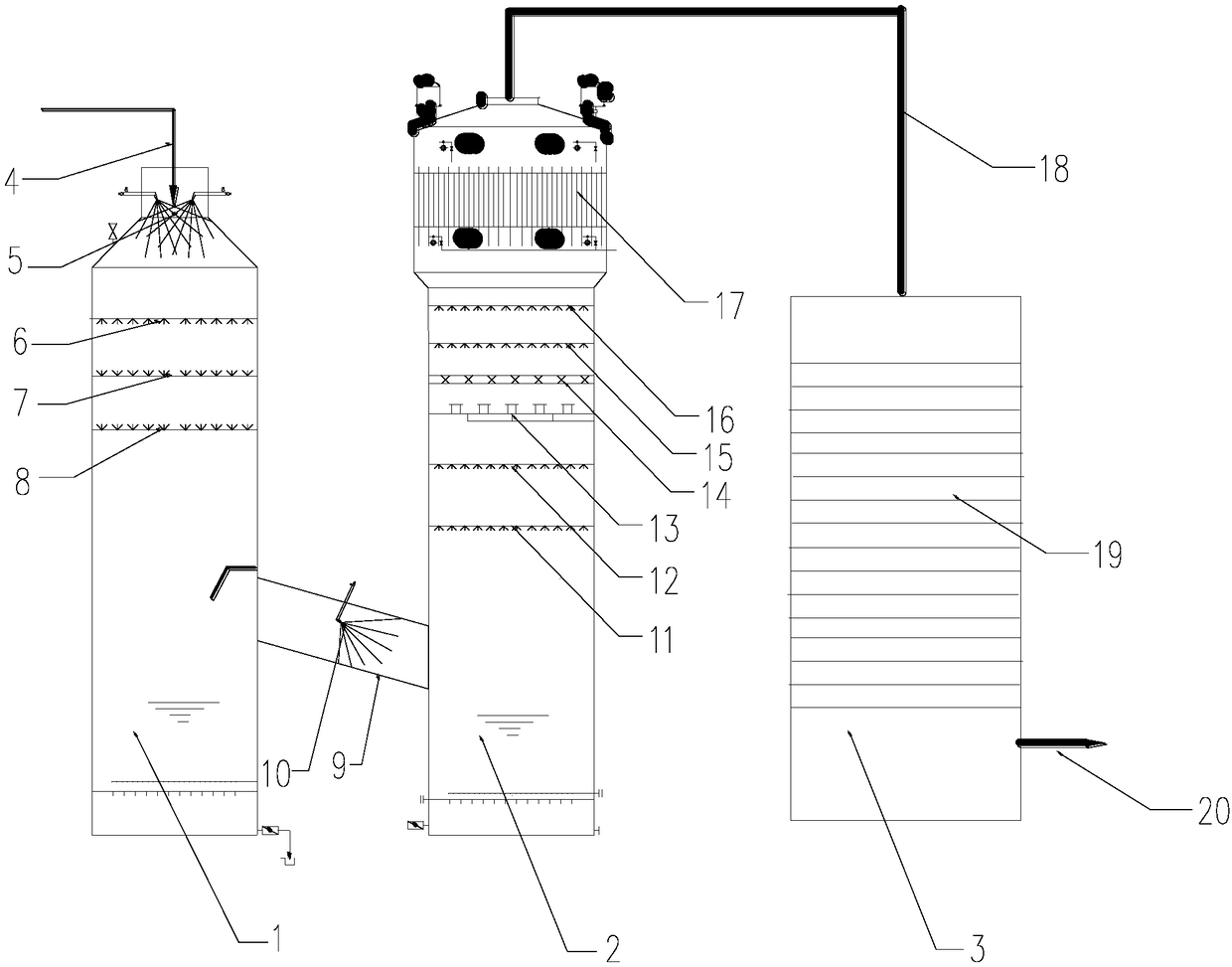

[0036] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0037] figure 1 A kind of ultra-clean discharge ammonia method desulfurization device shown, comprises the pre-washing tower 1, absorption tower 2 and adsorption tower 3 that are connected successively, and the top of described pre-washing tower is provided with flue gas inlet 4, and described pre-washing tower 1 Along the direction of flue gas movement, there are aerosol condensation water washing layer 5, the first pre-washing tower slurry spraying layer 6 with the water jet direction facing downward, and the second pre-washing tower slurry spraying layer 7 with the water jet direction facing upwards. and the third pre-washing tower slurry spray layer 8 facing upwards in the jet flow direction, the side wall of the pre-washing tower 1 is connected with the side wall of the absorption tower 2 through a flue gas channel 9, and the absorption tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com