Automatic programming system and method based on augmented reality, for movement track of robot

A technology of robot motion and augmented reality, applied in manipulators, program control manipulators, auxiliary devices, etc., can solve the problems of long time, high technical threshold, low efficiency, etc., to achieve strong operability and improve programming efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

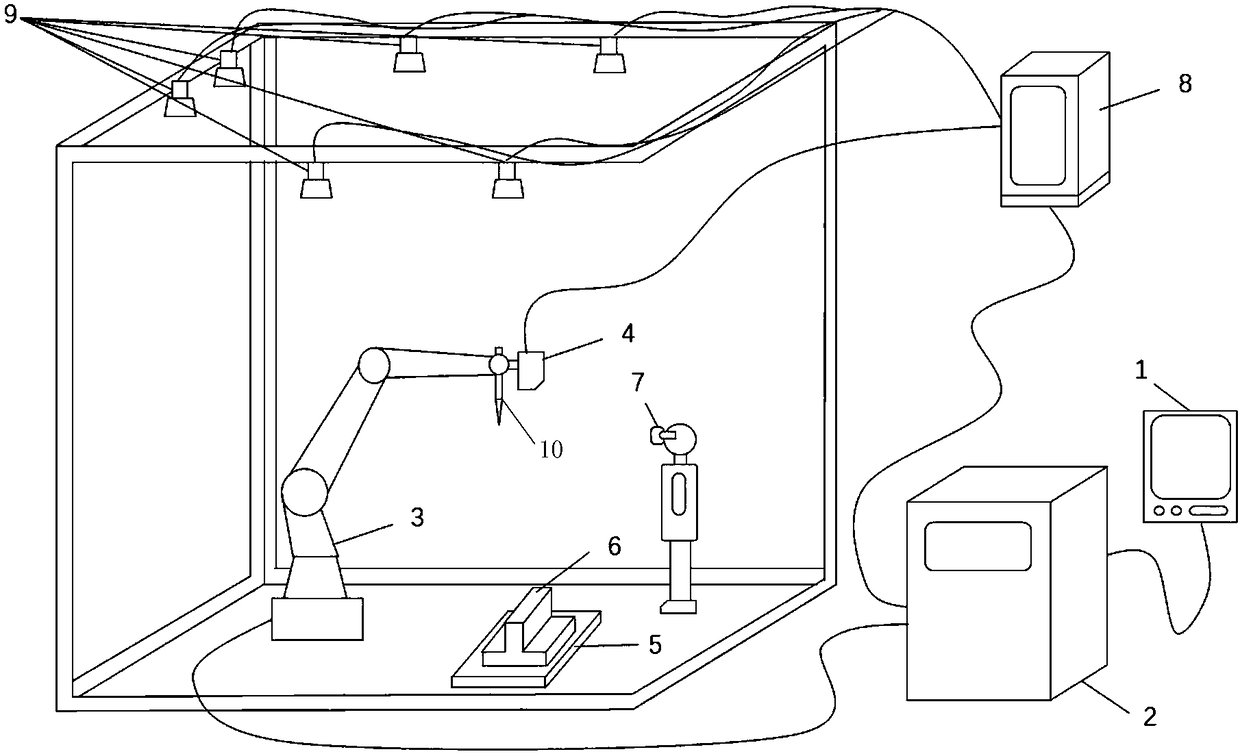

[0033] see figure 1 , the present invention is based on an augmented reality robot welding trajectory automatic programming system, including a teaching system, a robot system, a data processing system 8 and a T-shaped workpiece 6 to be welded,

[0034] The teaching system includes a helmet-mounted augmented reality display device 7 and a camera system 9. The helmet-mounted augmented reality display device 7 simulates an augmented reality scene and superimposes a three-dimensional model of a virtual workpiece; The workpiece 6 and the area where the helmet-mounted enhanced display device 7 is located) are connected to the data processing system 8, and the data processing system 8 is connected to the robot controller 2. In the process of collecting feature points, the camera uploads the pictures captured in real time to the data processing system 8, and uploads them to the robot controller 2 after being processed and converted by the data processing system 8, so as to realize th...

Embodiment 2

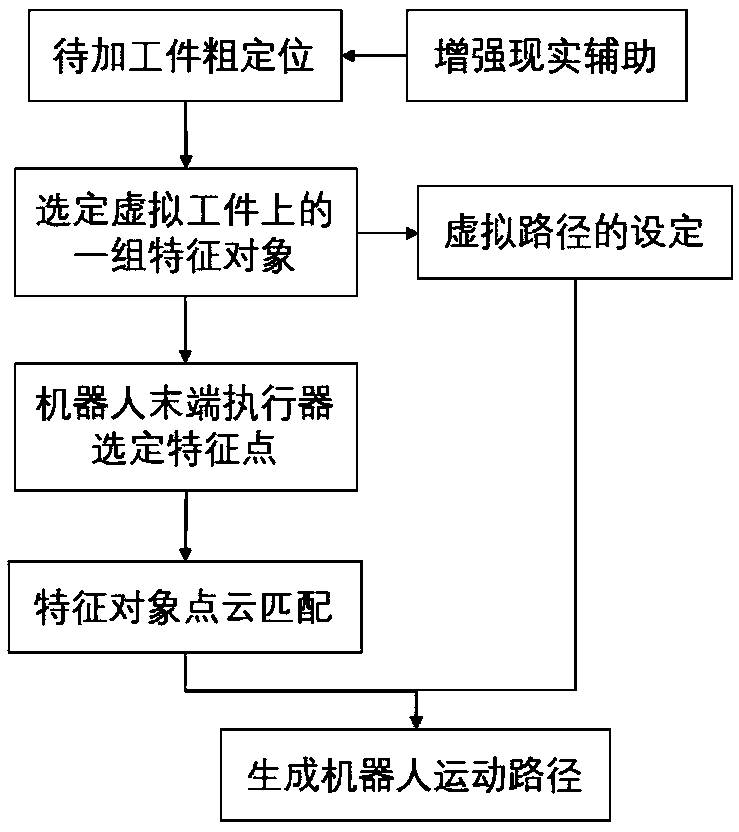

[0038] see figure 2 , on the basis of automatic programming system, the present invention proposes a kind of robot welding track automatic programming method based on augmented reality, comprises the following steps:

[0039] (1) Utilize augmented reality technology, superimpose and display the three-dimensional model of the virtual T-shaped workpiece in the field of vision through the helmet-type augmented reality display device 7, adjust and place the T-shaped workpiece 6 to be welded at a position roughly overlapping with the three-dimensional model, and complete the T Coarse positioning of workpieces;

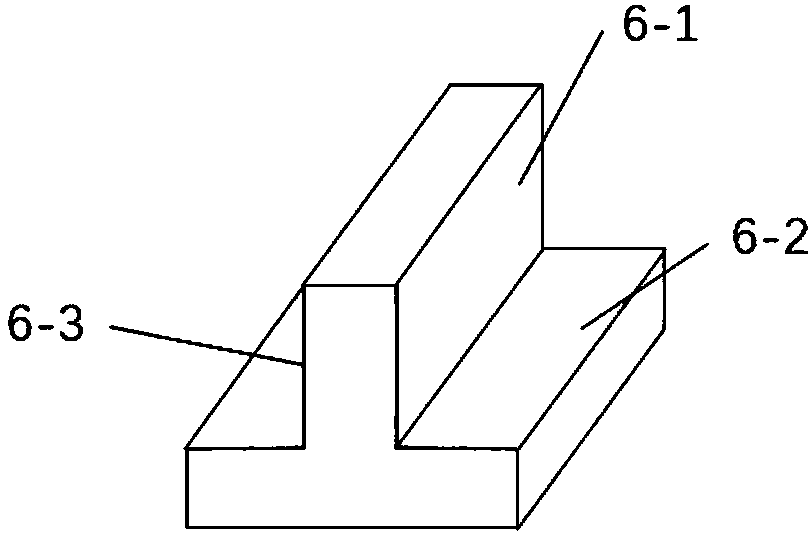

[0040] (2) In the augmented reality scene, specify the combination of a series of feature objects of the 3D model of the virtual T-shaped workpiece. see image 3 , the selected feature objects are the vertical plane 6-1, the horizontal plane 6-2, and the edge 6-3 of the T-shaped workpiece, and the intersection line between the edge 6-3 and the vertical plane 6-1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com