GIL insulator design method with surface conductivity two-dimensional U-type gradient distribution

A surface conductance and gradient distribution technology, applied in the field of high-voltage equipment manufacturing, can solve problems such as discharge, equipment failure, and electric field distortion, and achieve the effects of optimizing material structure, improving performance, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

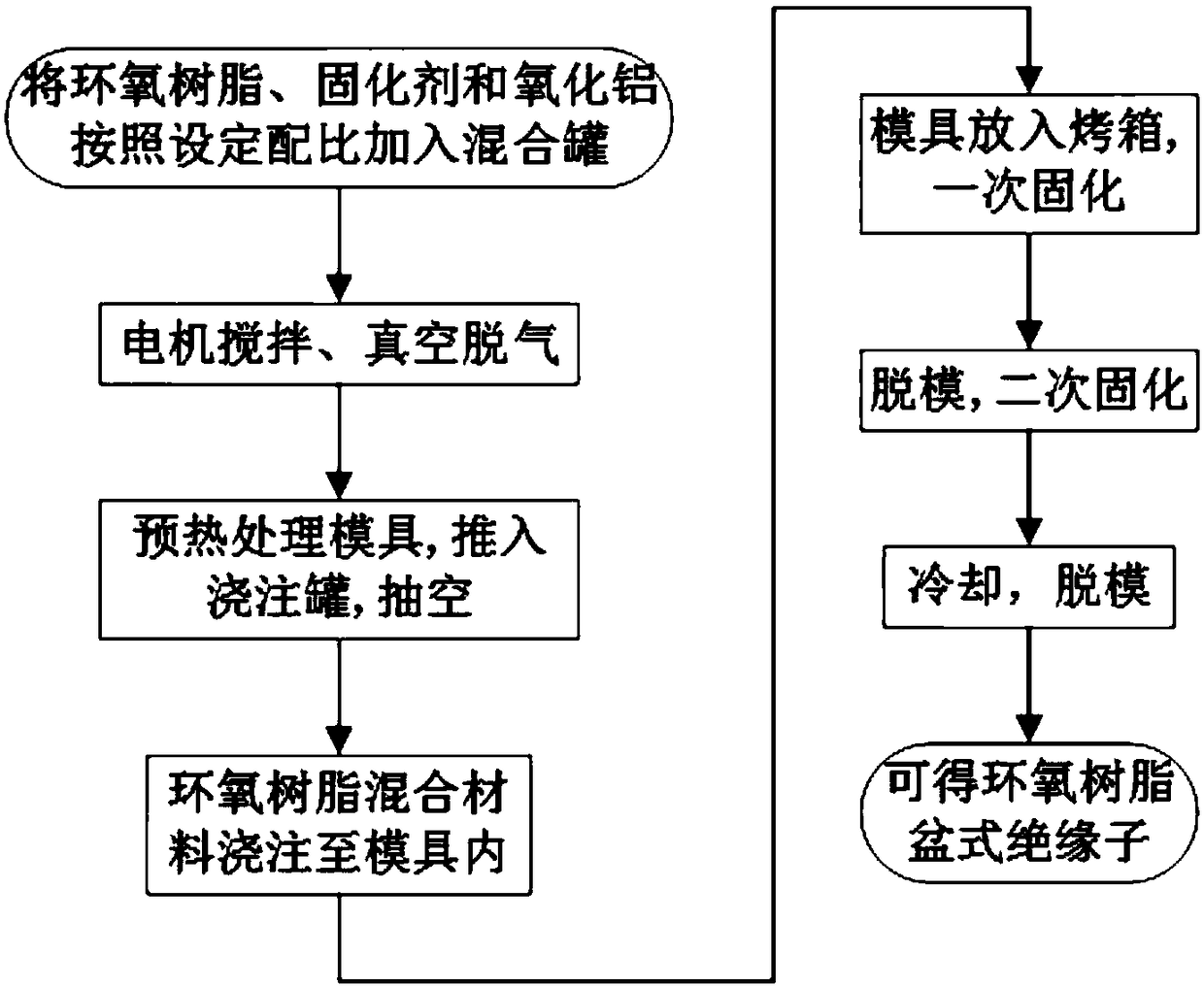

[0030] 1) Put epoxy resin, curing agent and alumina into the mixing tank according to the ratio of 100:38:330, the temperature is 130°C, turn on the motor to stir, vacuum degassing; push the preheated mold into the pouring tank, and carry out Evacuation treatment; pour the mixed epoxy resin mixture into the mold through the pouring equipment.

[0031] 2) Epoxy resin is processed by step curing method. The curing process is divided into two steps: first put the mold after vacuum treatment into the oven for primary curing, then demould, put it into the oven again for secondary curing, and get the product after cooling Epoxy resin pot insulators.

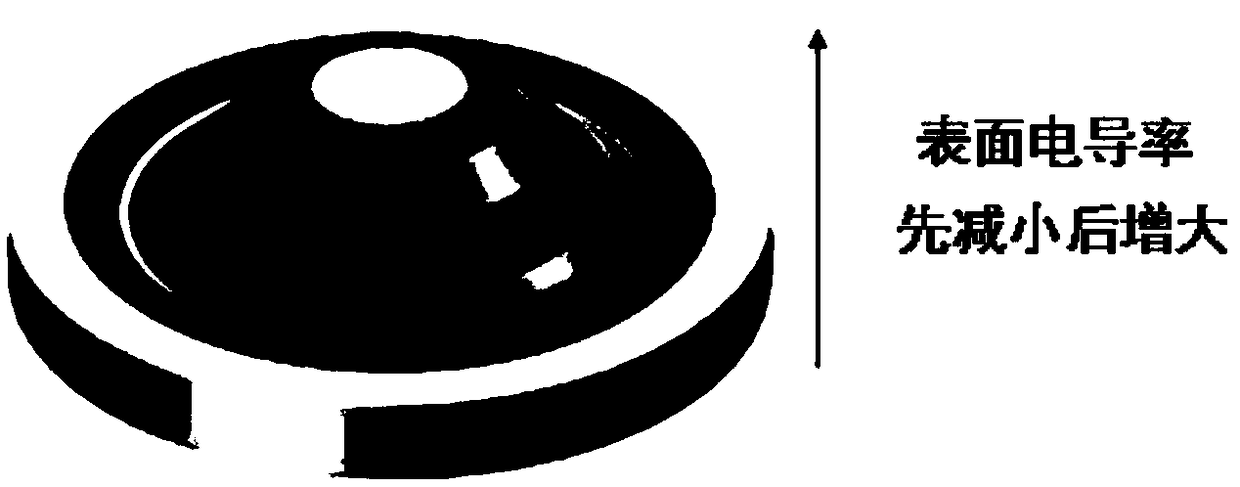

[0032] 3) U-shaped gradient design is carried out on the surface of the pot insulator, and the surface of the insulator is divided into five closely connected annular areas from the inside to the outside. The designed surface conductance first decreases and then increases. Place the sample in the fluorination treatment equipment, and ...

Embodiment 2

[0034] 1) Put epoxy resin, curing agent and alumina into the mixing tank according to the ratio of 100:38:330, the temperature is 130°C, turn on the motor to stir, vacuum degassing; push the preheated mold into the pouring tank, and carry out Evacuation treatment; pour the mixed epoxy resin mixture into the mold through the pouring equipment.

[0035] 2) Epoxy resin is processed by step curing method. The curing process is divided into two steps: first put the mold after vacuum treatment into the oven for primary curing, then demould, put it into the oven again for secondary curing, and get the product after cooling Epoxy resin pot insulators.

[0036] 3) U-shaped gradient design is carried out on the surface of the pot insulator, and the surface of the insulator is divided into five closely connected annular areas from the inside to the outside. The designed surface conductance first decreases and then increases. Place the sample in the fluorination treatment equipment, and ...

Embodiment 3

[0038] 1) Put epoxy resin, curing agent and alumina into the mixing tank according to the ratio of 100:38:330, the temperature is 130°C, turn on the motor to stir, vacuum degassing; push the preheated mold into the pouring tank, and carry out Evacuation treatment; pour the mixed epoxy resin mixture into the mold through the pouring equipment.

[0039] 2) Epoxy resin is processed by step curing method. The curing process is divided into two steps: first put the mold after vacuum treatment into the oven for primary curing, then demould, put it into the oven again for secondary curing, and get the product after cooling Epoxy resin pot insulators.

[0040] 3) U-shaped gradient design is carried out on the surface of the pot insulator, and the surface of the insulator is divided into five closely connected annular areas from the inside to the outside. The designed surface conductance first decreases and then increases. Place the sample in the fluorination treatment equipment, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com