Cultivating method for improving production capacity of micromonospora

A Micromonospora production capacity technology, applied in the field of cultivation to improve Micromonospora production capacity, can solve the problems of Micromonospora easy to decline, and achieve the effect of increasing production and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

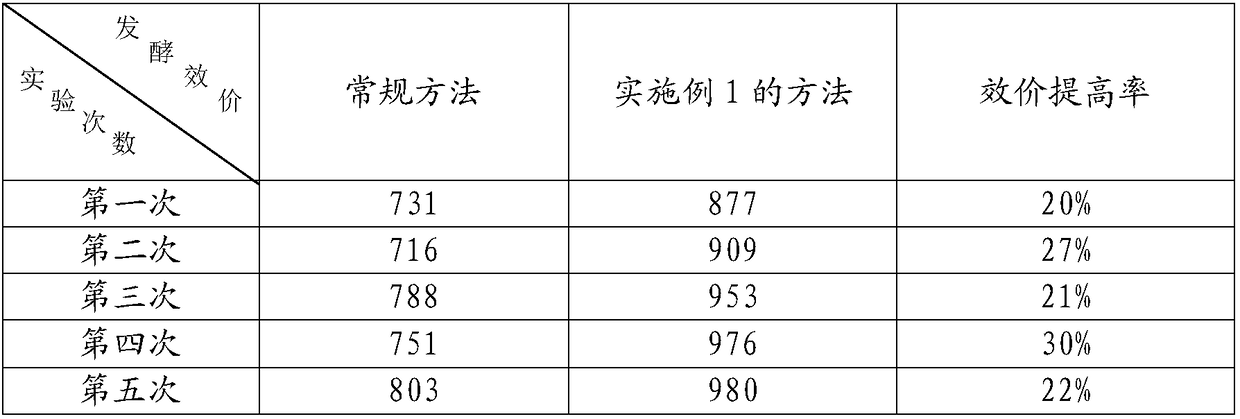

Embodiment 1

[0057] A culture method for improving Micromonospora production capacity, comprising the following steps:

[0058] Step 1: Inoculate the single colony of Micromonospora obtained by isolation and purification culture into the slant medium, cultivate for 11 days, and obtain the first colony; the slant medium is configured by the following formula:

[0059] Soluble starch 7.5g / L; sodium chloride 0.5g / L; potassium dihydrogen phosphate 0.3g / L; sodium nitrate 1.0g / L; calcium carbonate 1.0g / L; agar powder 17g / L;

[0060] The separation and purification culture method is as follows: inoculate Micromonospora species into the separation and purification medium, and cultivate for 13 days to obtain a single Micromonospora colony with a diameter of 4-6 mm and a height of 3-4 mm; the separation and purification culture The base is configured from the following recipe:

[0061] Soluble starch 7.5g / L; sodium chloride 0.5g / L; potassium dihydrogen phosphate 0.3g / L; sodium nitrate 1.0g / L; calci...

Embodiment 2

[0073] A culture method for improving Micromonospora production capacity, comprising the following steps:

[0074] Step 1: Inoculate the single colony of Micromonospora obtained by isolation and purification culture into the slant medium, cultivate for 11 days, and obtain the first colony; the slant medium is configured by the following formula:

[0075] Soluble starch 7.0g / L; sodium chloride 0.3g / L; potassium dihydrogen phosphate 0.2g / L; sodium nitrate 0.8g / L; calcium carbonate 0.8g / L; agar powder 15g / L;

[0076] The separation and purification culture method is as follows: inoculate Micromonospora species into the separation and purification medium, and cultivate for 13 days to obtain a single Micromonospora colony with a diameter of 4-6 mm and a height of 3-4 mm; the separation and purification culture The base is configured from the following recipe:

[0077] Soluble starch 7.0g / L; sodium chloride 0.3g / L; potassium dihydrogen phosphate 0.2g / L; sodium nitrate 0.8g / L; calci...

Embodiment 3

[0086] A culture method for improving Micromonospora production capacity, comprising the following steps:

[0087] Step 1: Inoculate the single colony of Micromonospora obtained by isolation and purification culture into the slant medium, cultivate for 11 days, and obtain the first colony; the slant medium is configured by the following formula:

[0088] Soluble starch 8.0g / L; sodium chloride 0.7g / L; potassium dihydrogen phosphate 0.4g / L; sodium nitrate 1.2g / L; calcium carbonate 1.2g / L; agar powder 19g / L;

[0089] The separation and purification culture method is as follows: inoculate Micromonospora species into the separation and purification medium, and cultivate for 13 days to obtain a single Micromonospora colony with a diameter of 4-6 mm and a height of 3-4 mm; the separation and purification culture The base is configured from the following recipe:

[0090] Soluble starch 8.0g / L; sodium chloride 0.7g / L; potassium dihydrogen phosphate 0.4g / L; sodium nitrate 1.2g / L; calci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com