Preparation method of iron series additive and method for increasing anaerobically produced methane

An anaerobic methane production and additive technology, applied in waste fuel, fermentation and other directions, can solve the problems affecting the resource utilization of biogas residue and biogas slurry, high treatment and disposal costs, and increased iron dosage, and achieve resource utilization. , the effect of reducing the amount of iron added and operating costs, and promoting the production of methane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

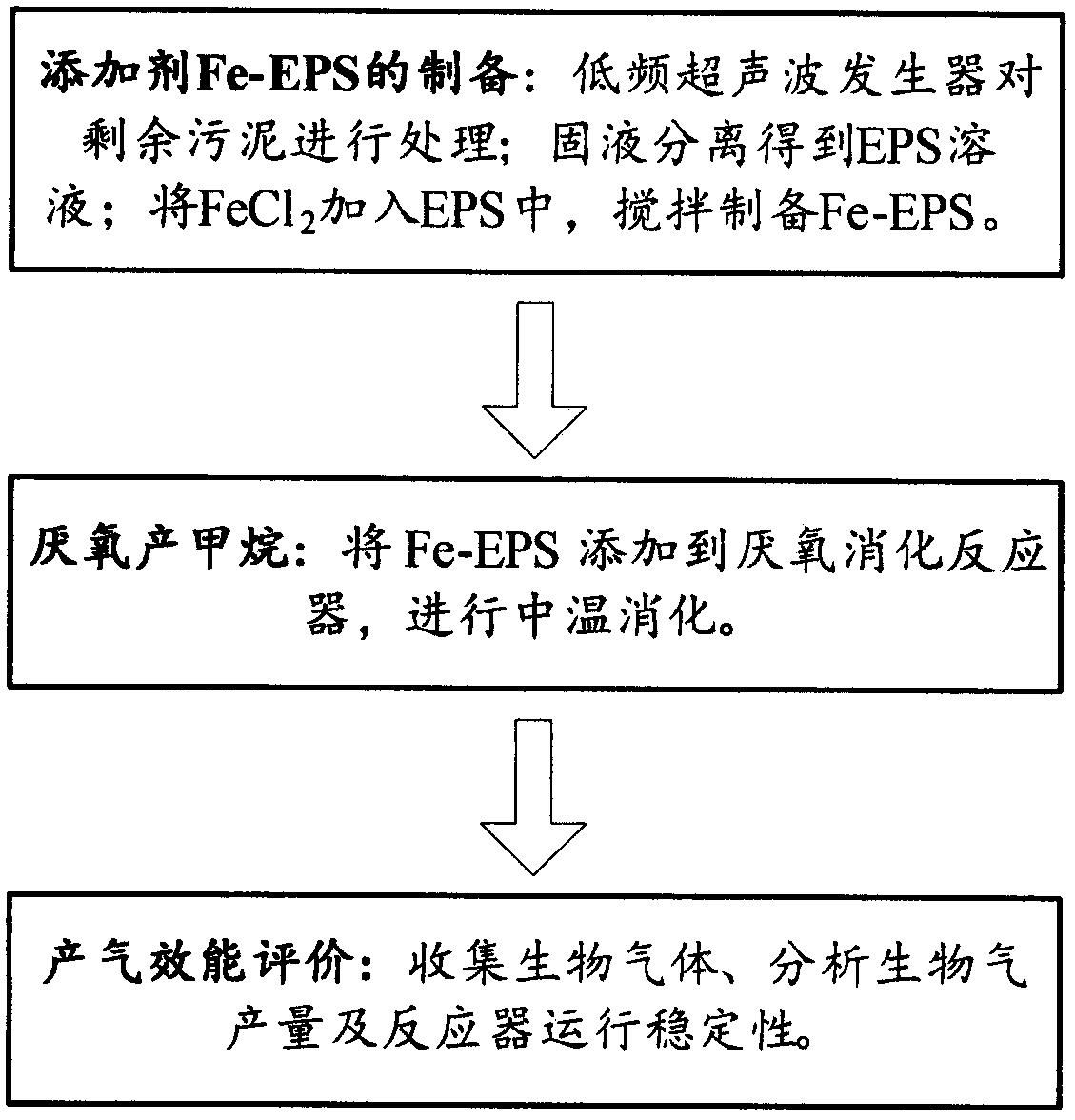

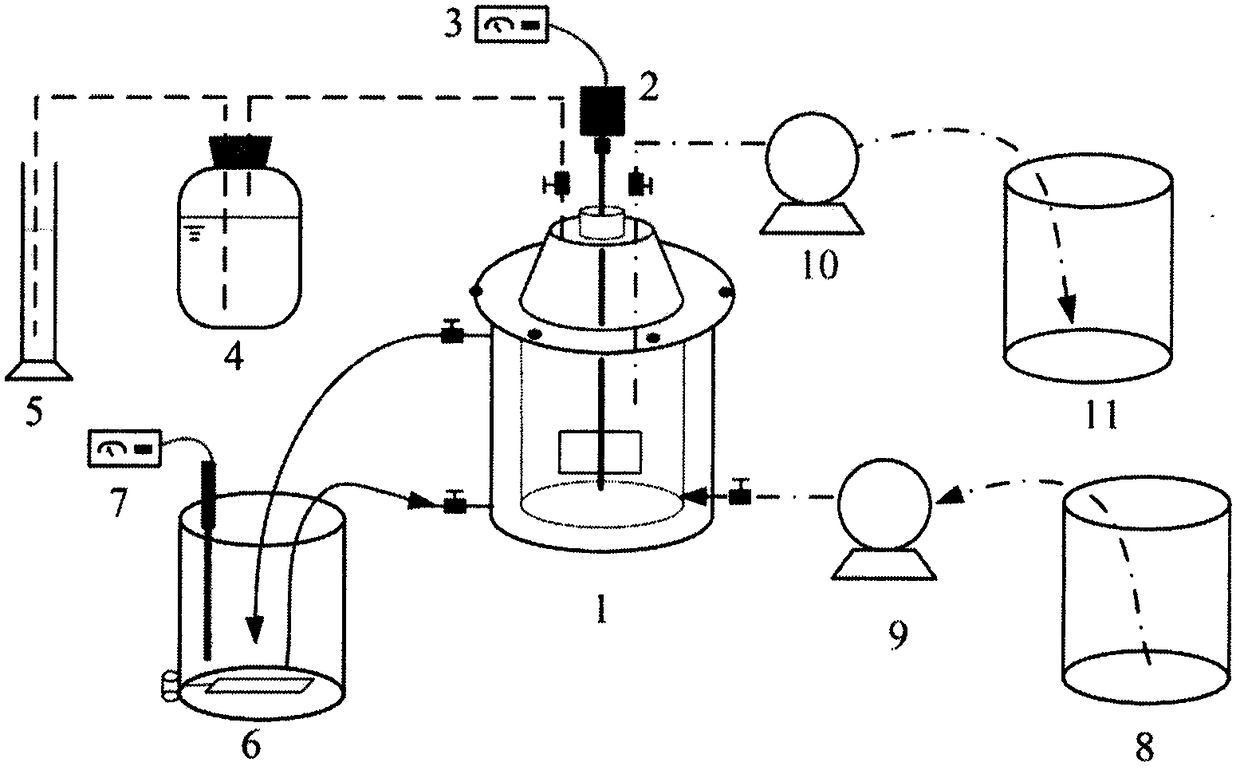

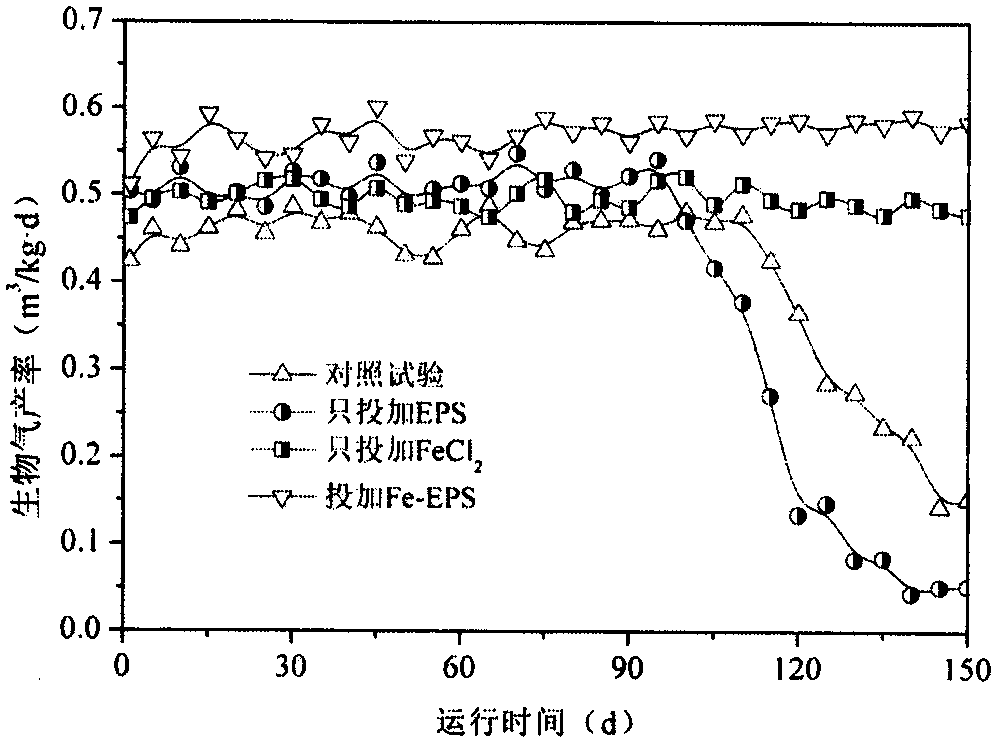

[0056] The present embodiment provides a preparation of iron-based additives and a method for improving anaerobic methanogenesis, which is implemented in the above-mentioned anaerobic digestion device, and specifically includes the following steps:

[0057] After washing the collected food waste with tap water, manually pick out the bones, plastic products, paper towels and other sundries in the food waste, and then heat and mash the food waste to <2mm.

[0058] The collected sludge from the secondary sedimentation tank of the municipal sewage treatment plant was filtered through a 1mm sieve, and then stood at 4°C for 24 hours. After the supernatant was discharged, the sludge was ultrasonically treated with a 20kHz low-frequency ultrasonic generator (1.0 W / mL, 5min). The remaining sludge after ultrasonic treatment was centrifuged with a centrifuge (8000rpm) for 10 minutes to obtain an EPS solution. Then 400mg of FeCl 2 The solid was slowly added to 1L of EPS solution and sti...

Embodiment 2

[0063] The present embodiment provides a preparation of iron-based additives and a method for improving anaerobic methanogenesis, which is implemented in the above-mentioned anaerobic digestion device, and specifically includes the following steps:

[0064] After washing the collected food waste with tap water, manually pick out the bones, plastic products, paper towels and other sundries in the food waste, and then heat and mash the food waste to <2mm.

[0065] The collected sludge from the secondary sedimentation tank of the municipal sewage treatment plant was filtered through a 1mm sieve, and then stood at 4°C for 24 hours. After the supernatant was discharged, the sludge was ultrasonically treated with a 20kHz low-frequency ultrasonic generator (1.0 W / mL, 5min). The remaining sludge after ultrasonic treatment was centrifuged with a centrifuge (8000rpm) for 10 minutes to obtain an EPS solution. Then 400mg of FeCl 2 The solid was slowly added to 1L of EPS solution and sti...

Embodiment 3

[0070] The present embodiment provides a preparation of iron-based additives and a method for improving anaerobic methanogenesis, which is implemented in the above-mentioned anaerobic digestion device, and specifically includes the following steps:

[0071] After washing the collected food waste with tap water, manually pick out the bones, plastic products, paper towels and other sundries in the food waste, and then heat and mash the food waste to <2mm.

[0072] The collected sludge from the secondary sedimentation tank of the municipal sewage treatment plant was filtered through a 1mm sieve, and then stood at 4°C for 24 hours. After the supernatant was discharged, the sludge was ultrasonically treated with a 20kHz low-frequency ultrasonic generator (1.0 W / mL, 5min). The remaining sludge after ultrasonic treatment was centrifuged with a centrifuge (8000rpm) for 10 minutes to obtain an EPS solution. Then 400mg of FeCl 2 The solid was slowly added to 1L of EPS solution and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com