Motor-drive circuit having frequency setting and correcting function and method thereof

A driving circuit and motor technology, applied in the direction of single motor speed/torque control, etc., can solve the problems of motor speed and frequency drift, achieve the effects of improving manufacturing yield, preventing drift, and maintaining operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

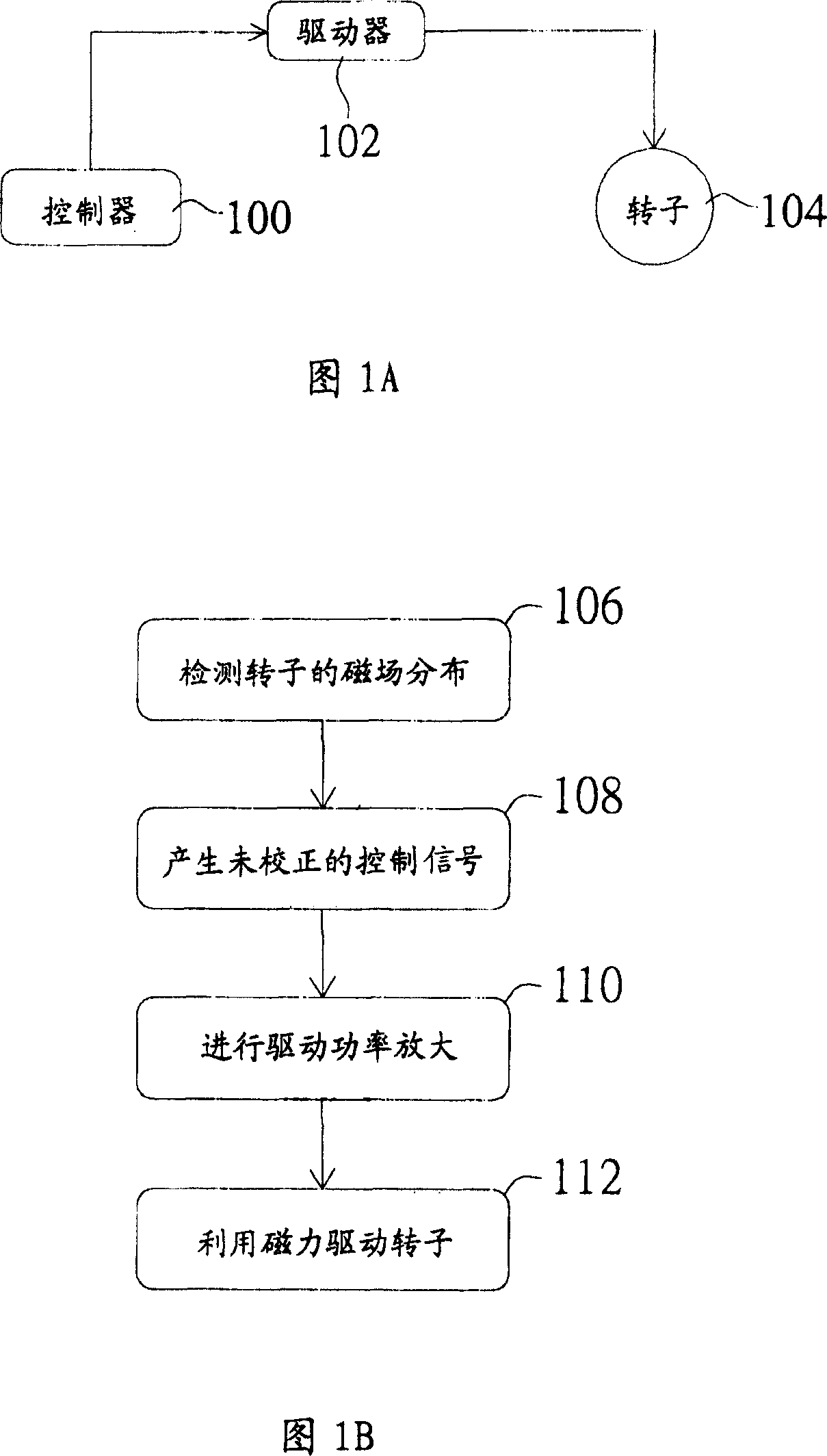

[0087] The present invention provides a complete solution to the deficiencies of the prior art. The motor drive circuit with frequency setting and correction functions and its method are described in detail with the help of accompanying drawings. The motor drive circuit of the present invention is mainly applied to brushless DC motors, and is also suitable for controlling motors with different coil poles, such as motors with four poles, six poles, eight poles, twelve poles or higher poles. Generally speaking, the number of coil poles is directly proportional to the output horsepower of the motor, that is, the higher the number of poles, the greater the output horsepower. Specifically, the motor driving circuit can be applied to a single-coil brushless DC motor, as well as a double-coil brushless DC motor.

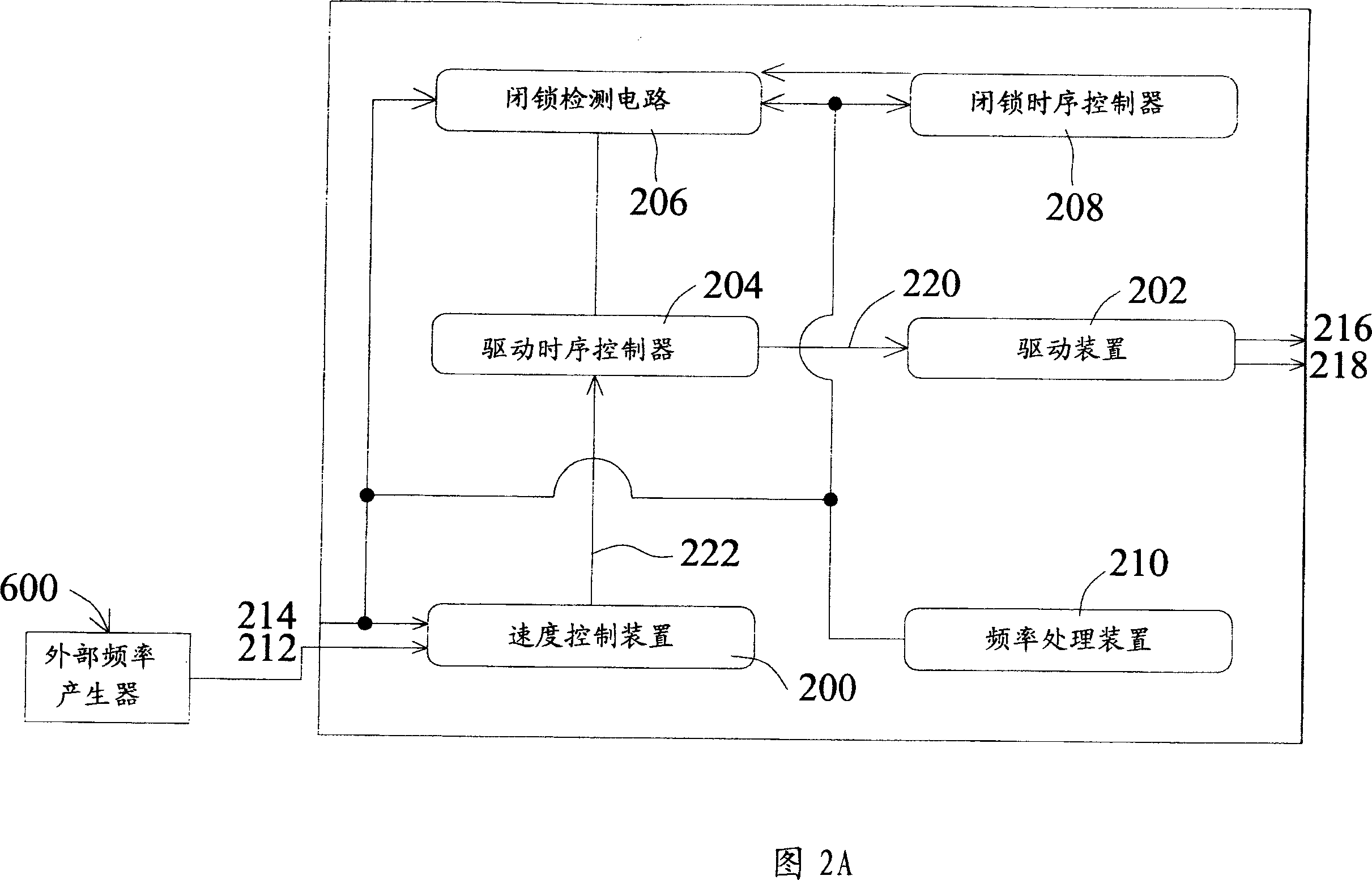

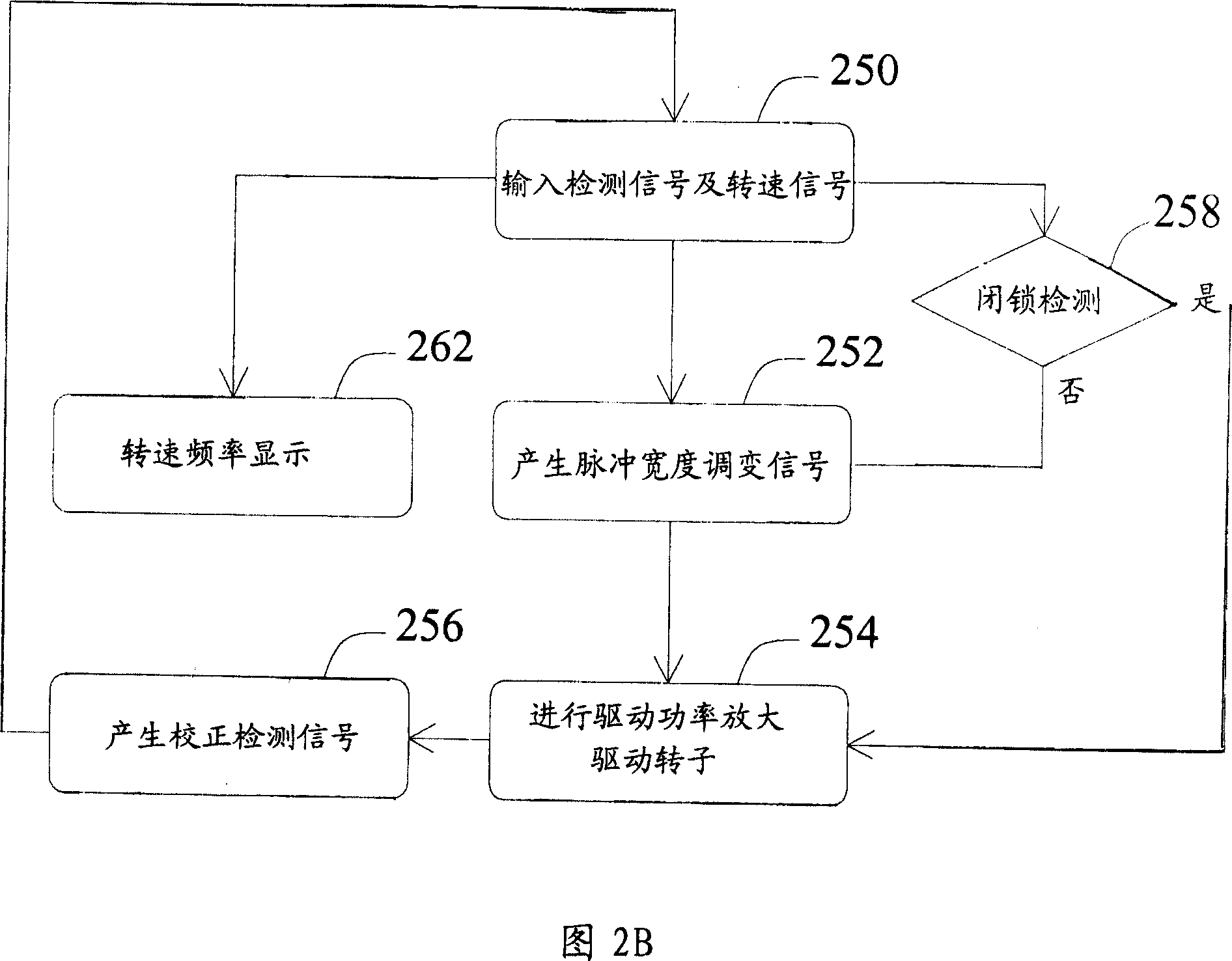

[0088] Please refer to FIG. 2A first, which shows a block diagram of the motor driving circuit of the present invention. The motor drive circuit at least includes a speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com