Filling type nodular cast iron well lid provided with structure technological ribs

A technology of ductile iron and craft ribs, applied in the field of filled ductile iron manhole covers, can solve the problems of improving labor intensity, increasing cost, adding materials, etc., and achieving the effect of reducing labor intensity, speeding up cooling speed, and avoiding cumbersomeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

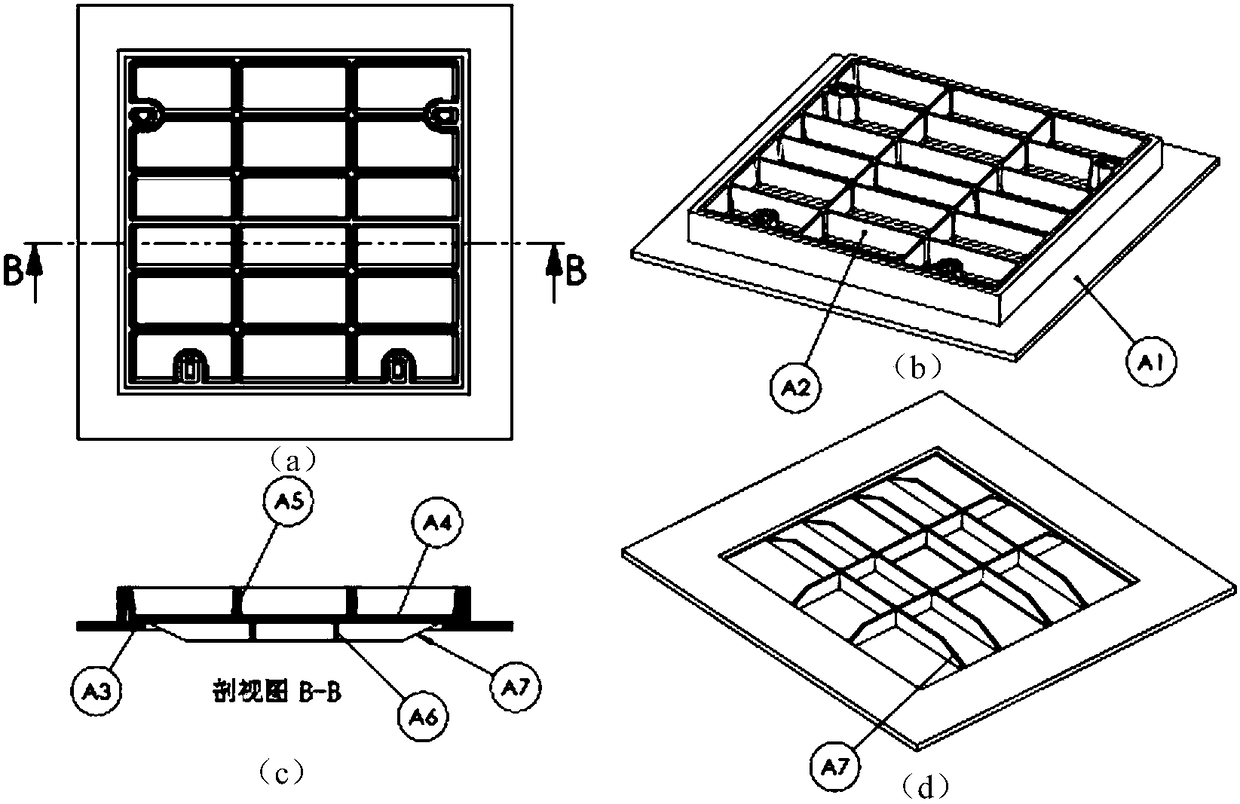

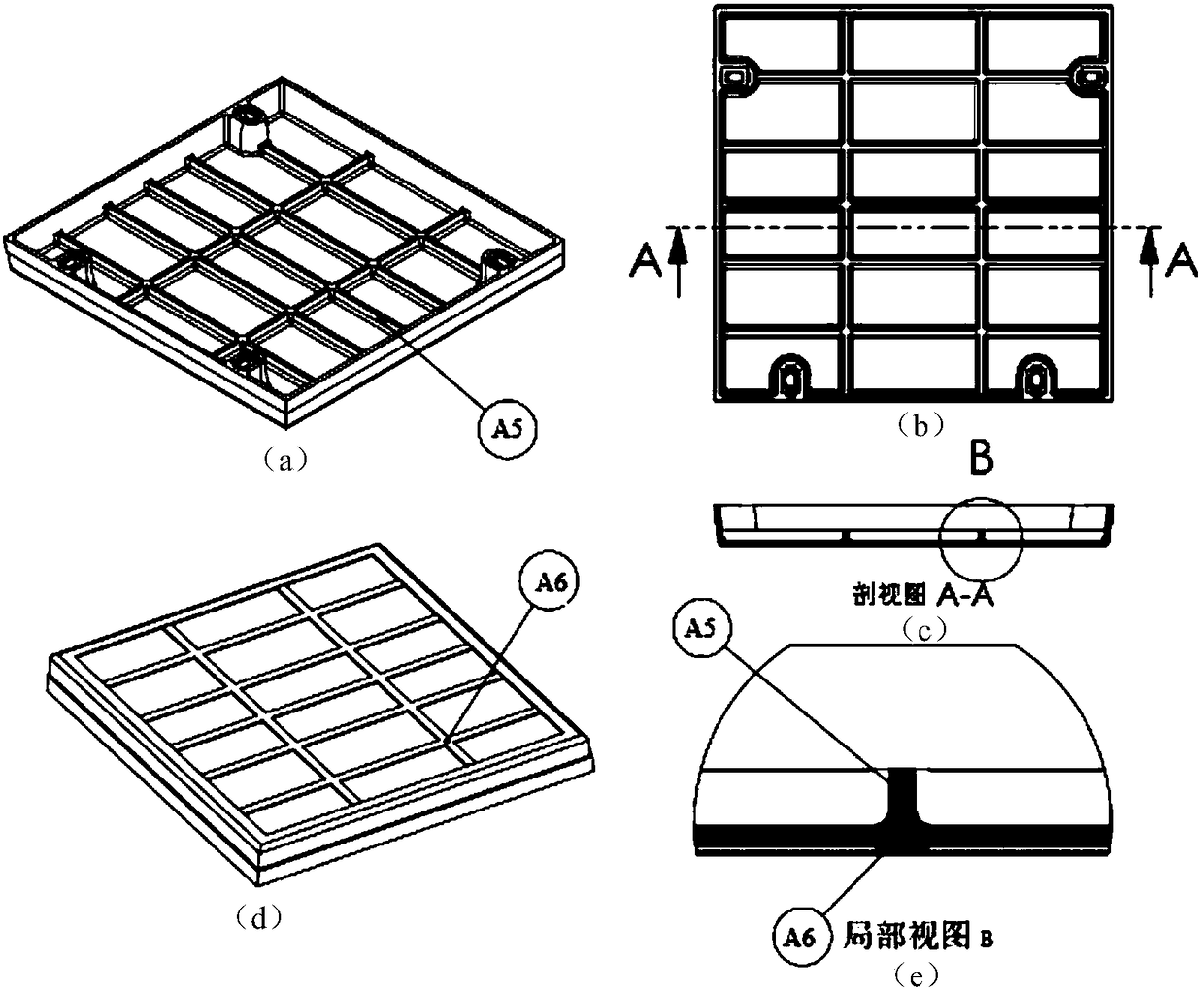

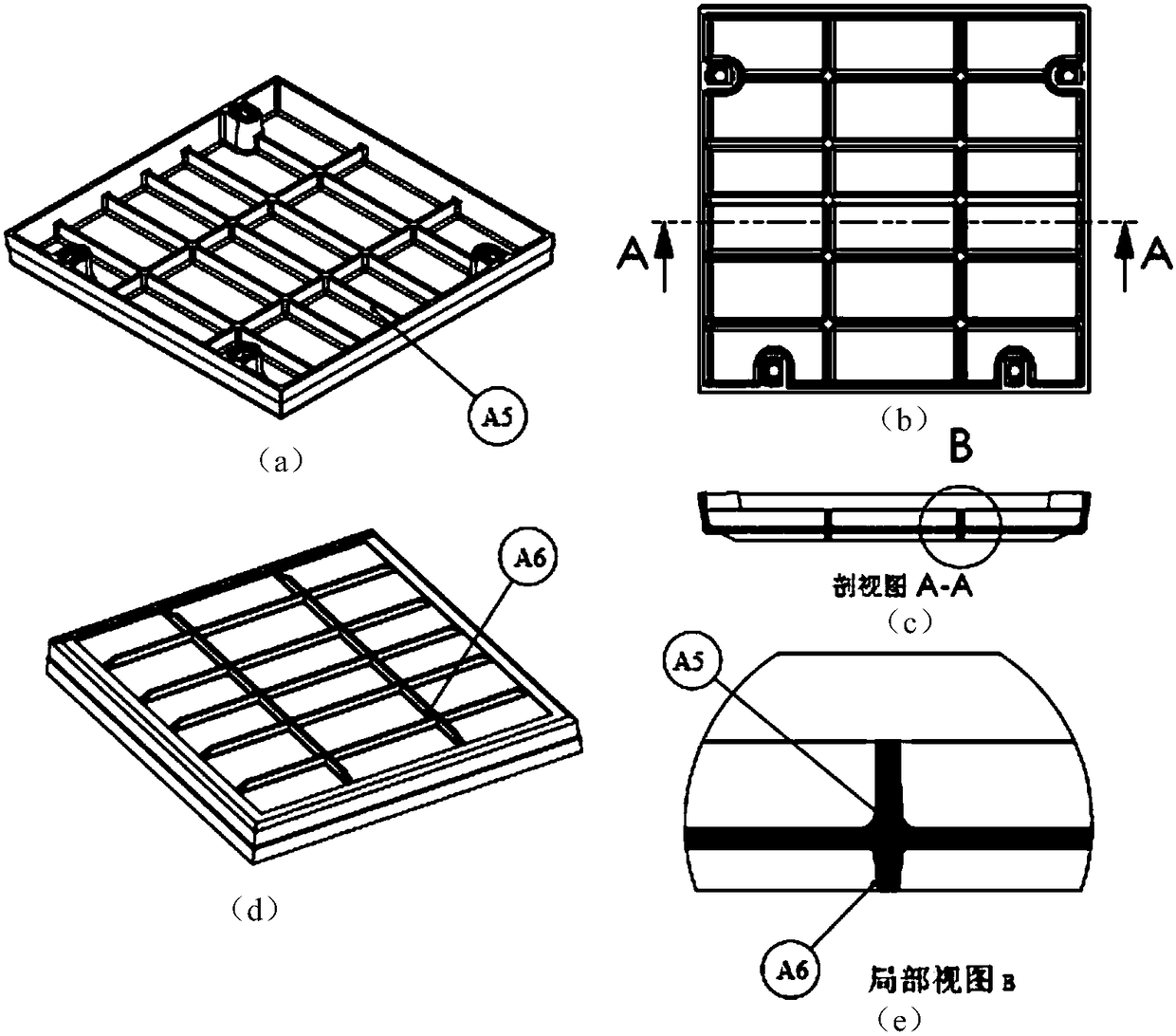

[0035] The following is attached Figure 1-4 The present invention is described in further detail.

[0036] Such as figure 1 As shown, a filled nodular cast iron manhole cover provided with structural process ribs includes: a well base A1 and a well cover body A2. A4, the front of the manhole cover main board A4 is provided with reinforcing ribs A5, and the back of the manhole cover main board A4 is provided with structural process ribs A6. The structural process ribs A6 are in a flat structure. The number of the structural process ribs A6 is set according to the load-bearing level requirements of the manhole cover Adjust; the setting position of the structural process rib A6 is adjusted according to the load-bearing level requirements of the well cover; the two ends of the structural process rib A6 are provided with structural process rib chamfers A7, which are used to avoid the structural process rib A6 from being too high or the position Inappropriate, resulting in inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com