Model shield machine cutter head pressure monitoring system capable of achieving function of excavation surface pressure monitoring

A pressure monitoring and shield machine technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of large influence of stratum conditions, high cost, and long field test period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

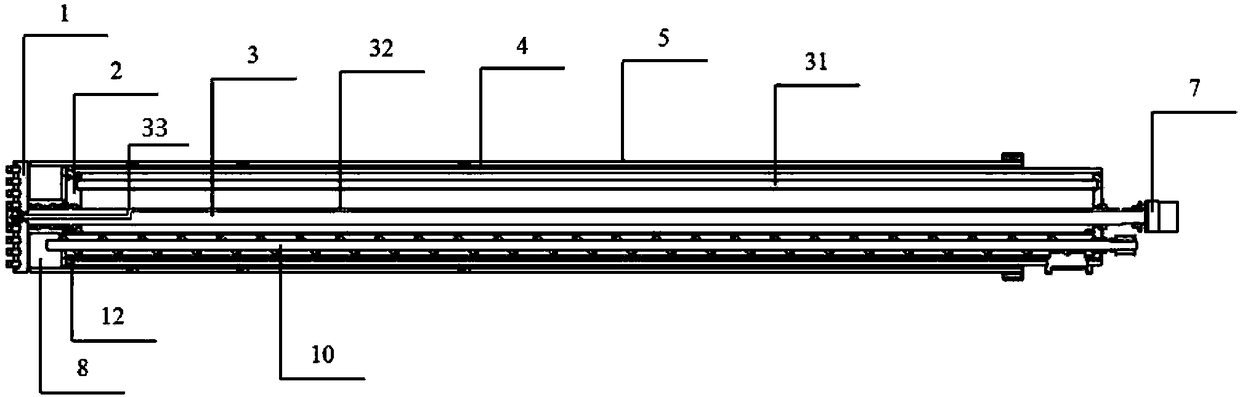

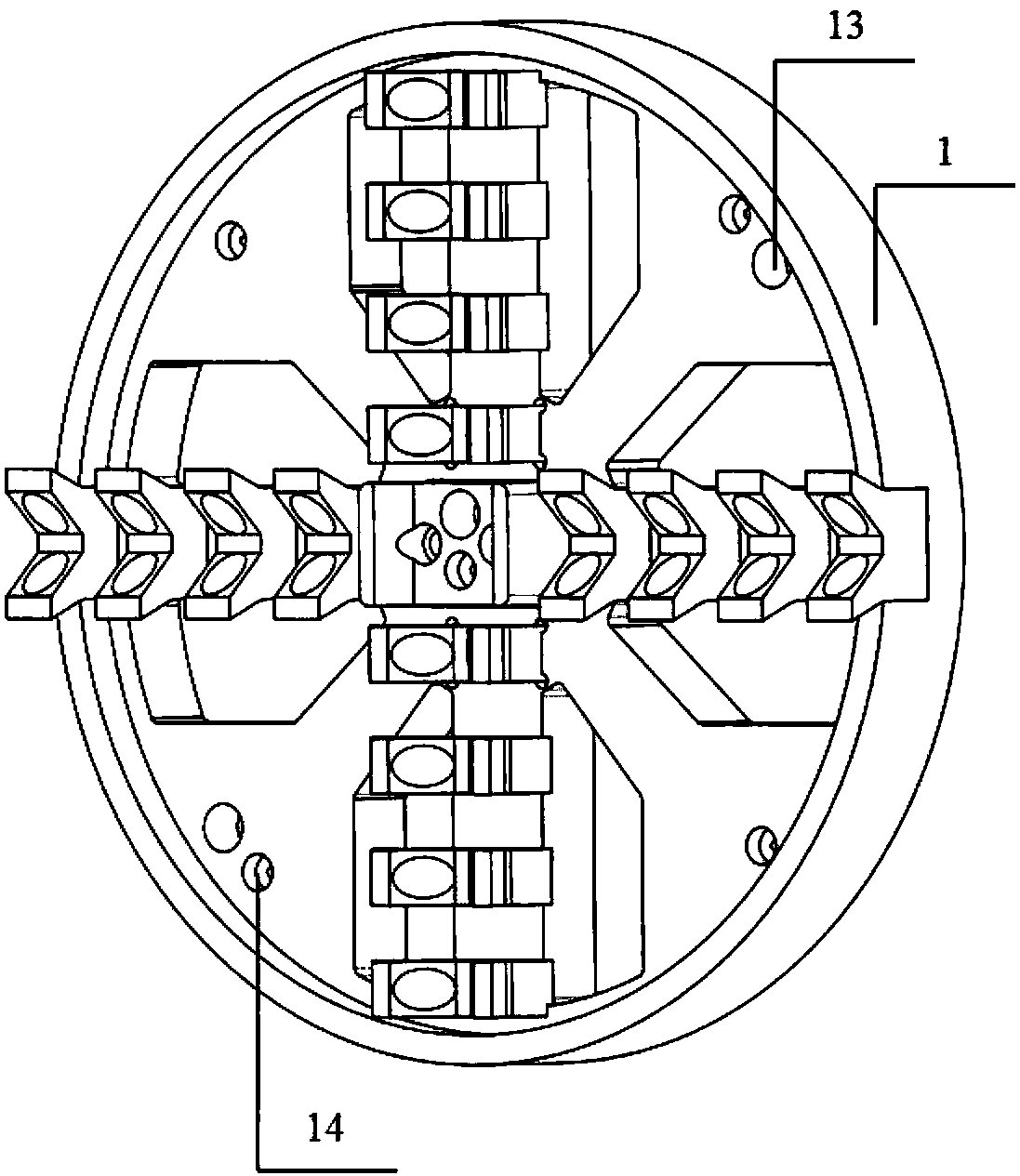

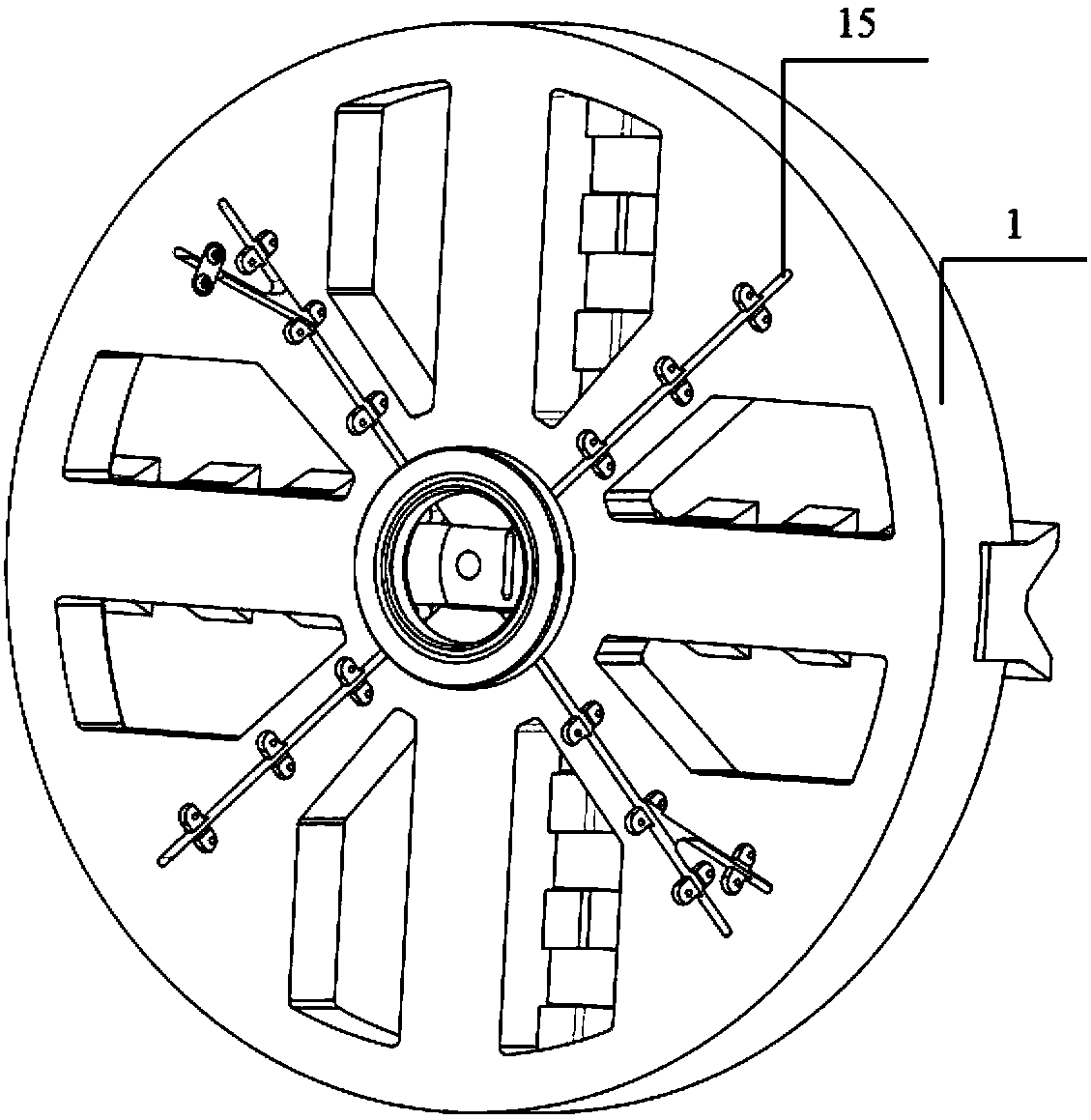

[0017] Earth pressure balance model shield machine includes cutter head (1), partition (2), cutter head bearing (3), shield shell (4), lining (5), screw excavator drive motor (6), wireless transmitter (7), the soil inlet extends into the soil ballast chamber (8), the assembled collar (9), the screw excavator (10), the earth pressure box (11), the assembled collar (12), the earth pressure sensor (13 ), piezometer (14), back wire slot (15), floating support (16), cutter head drive motor (17), lining jacking motor (18), two jacking screw screws (19), four Guide optical shaft (20), moving slider (21), timing pulley (22), reaction force frame (23), soil discharge port (24), muck box (25), assembly collar (26), heavy Supporting leg universal wheel (27), shield machine base (28), installation hole for guiding optical axis (29), front reserved excavation hole (30), lead pipe (31), lead groove (32), lead wire hole (33), see the attached Figure 4 .

[0018] In conjunction with the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com