A pulverized coal combustion boiler system and a pulverized coal combustion boiler operating method

A pulverized coal combustion and boiler operation technology, which is applied in the field of boiler combustion, can solve problems such as high fuel consumption and unstable combustion, and achieve cost reduction and avoid non-stop effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

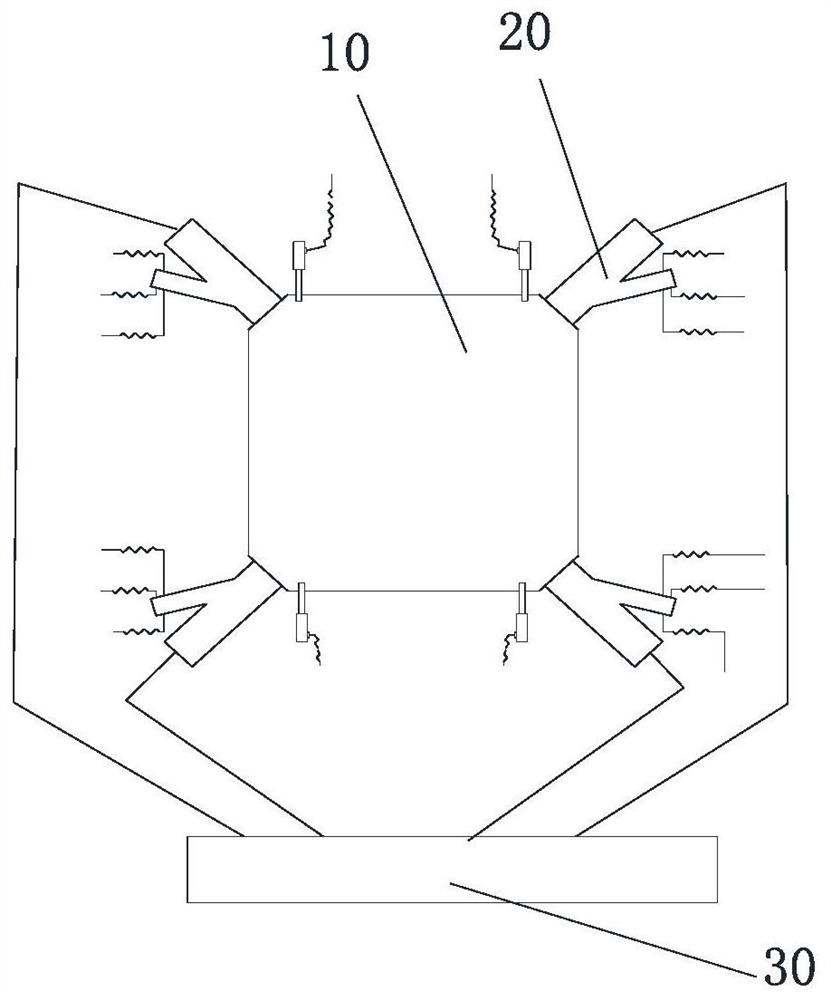

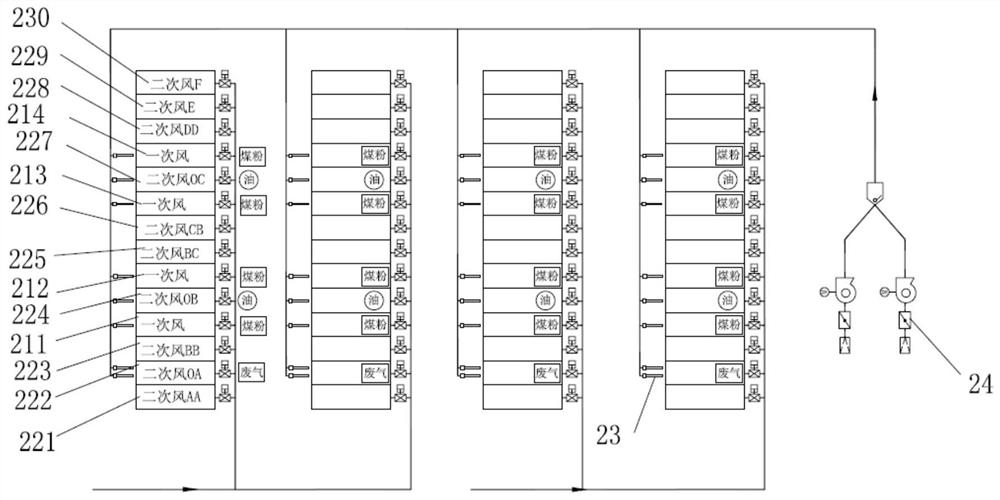

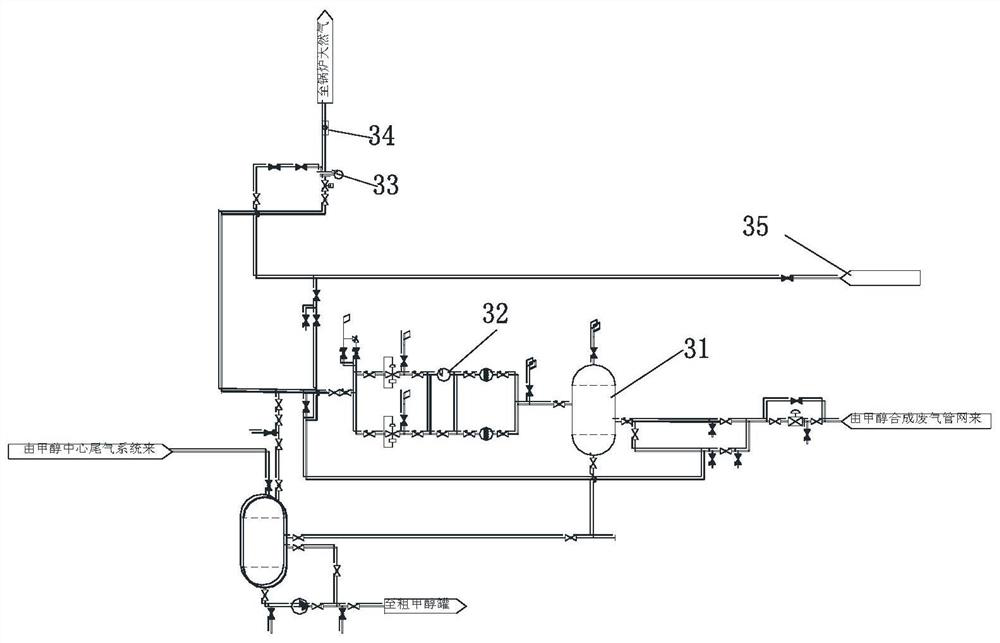

[0029] In order to solve the problem of high fuel consumption and unstable combustion in the pulverized coal combustion boiler system in the prior art, the inventors of the present application have studied the commonly used fuels and potential fuels in the prior art, and found that the waste gas discharged from the coal gasification methanol synthesis device has It has the characteristics of many combustible components, relatively high calorific value, easy ignition and fast burning speed. The waste gas emitted by the coal gasification methanol synthesis unit is mainly hydrogen, methane, ethane, carbon monoxide and other combustible gases and N 2 , CO 2 , argon and other incombustible gases a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com