Withering room, white tea production line and white tea production process

A technology of withering and tea leaves, which is applied in the field of tea making, can solve the problems of high labor cost, low processing efficiency, and large space occupied by tea leaves, and achieve the effect of increasing the withering speed, speeding up the speed, and smoothing the leaf surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

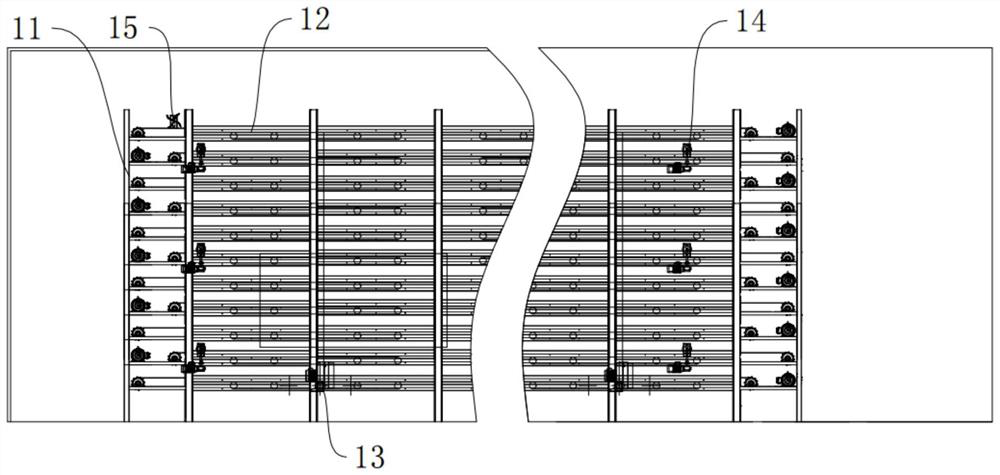

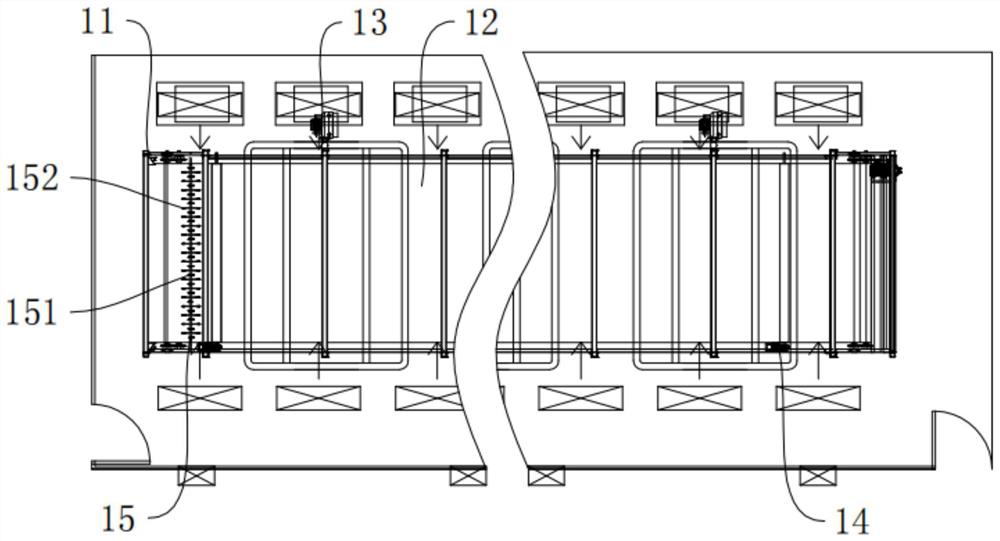

[0061] Embodiment 1: The present invention provides a withering room 1, which includes a frame 11, a conveyor belt 12, a fresh air supply device 13, a pressing device 14 and a material leveling mechanism 15. In this embodiment, the material is tea leaves as an example.

[0062] Frame 11 is arranged in the withering room, as the installation carrier of conveyor belt 12, fresh air supply device 13 and pressing device 14.

[0063] Conveyor belt 12 is used for conveying tealeaves, is preferably conveying mesh belt, and the belt surface of conveyer belt 12 is provided with ventilation holes, and conveyer belt 12 is provided with multiple and layered intervals between conveyer belts 12 and is arranged on frame 11, is used for from top to bottom one by one. The tea leaves are conveyed layer by layer; preferably, the conveyor belt 12 is arranged horizontally, and the head end of the conveyor belt 12 of the next layer is located at the end of the conveyor belt 12 of the previous layer, ...

Embodiment 2

[0070] Embodiment 2: Based on Embodiment 1, the present invention also provides a white tea production line, including a material feeding and leveling mechanism 2, a low-temperature zone withering room 1a, a transfer mechanism 3, a medium-temperature zone withering room 1b, and a withering discharge machine arranged in sequence. 4. Drying feeding machine 5, drying machine 6, drying discharge hoist 7, electrostatic feeding machine 8 and electrostatic hair separator 9, the withering room 1a in the low temperature zone and the withering room 1b in the middle temperature zone are those of embodiment 1 wither room 1;

[0071] Feeding and homogenizing mechanism 2, which is used to transport tea leaves to the withering room 1a in the low temperature zone; preferably, feeding and homogenizing mechanism 2 includes a hoist 21 and a homogenizing mechanism 22 for homogenizing the lifted tea leaves, Elevator 21 lifts the tealeaves to the front section of the top conveyor belt, and leveling...

Embodiment 3

[0082] Embodiment 3: based on embodiment 1 and 2, the present invention also provides a kind of white tea production process, comprises the following steps:

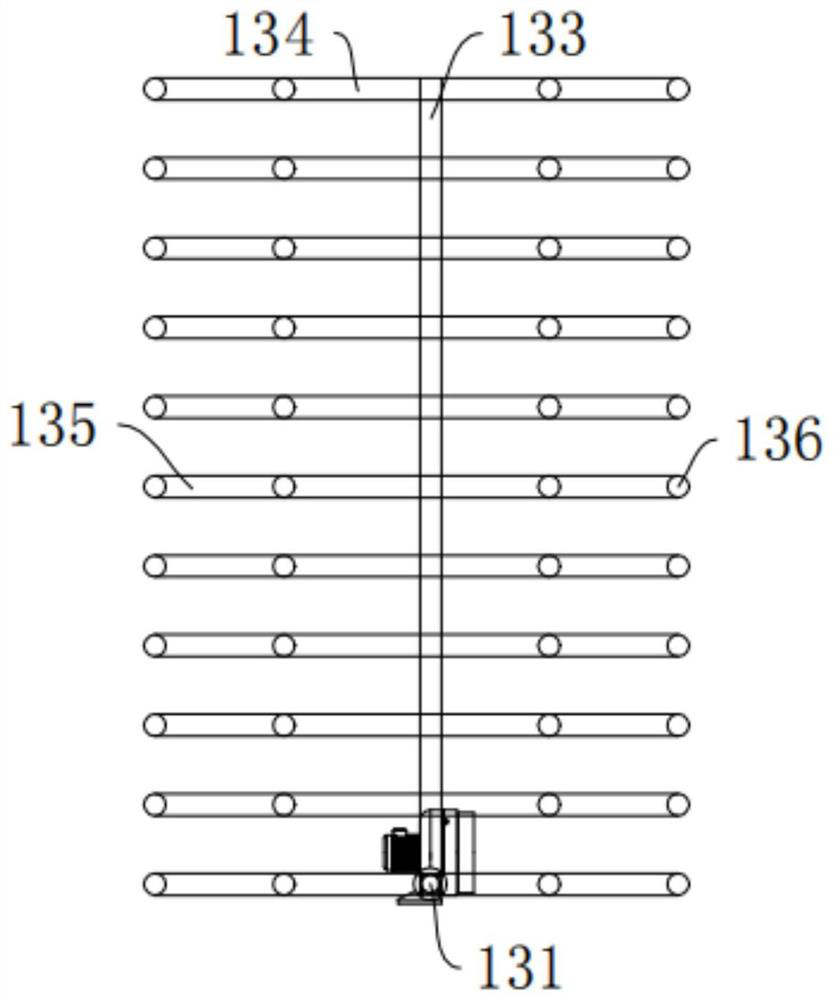

[0083] Step 1, withering: transport the tea leaves to the conveyor belt of the withering room in the low temperature area; the uniform material mechanism 15 performs uniform material on the tea leaves on the conveyor belt. and the toggle lever to limit the conveying height of the tea leaves; the air source 131 transmits air to the ventilation pipe 132, and the ventilation pipe 132 blows the bottom of the tea leaves through the ventilation holes; the visual detector 141 detects the height of the tea leaves and feeds back the height signal to the controller to control The device controls the lifting mechanism 143 to rise and fall according to the height signal, so that the height of the roller 142 is slightly lower than the height of the tea leaves; the tea leaves after blowing pass through the bottom of the roller 142, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com