Application of pressure paper to fuel cells

A technology of fuel cells and fuel cell stacks, applied in the direction of fuel cells, circuits, electrical components, etc., can solve the difficulty in ensuring the consistency and flatness requirements of the preparation process, the influence of the flatness accuracy of the measurement plate, and the inability to truly reflect Stack flatness and other issues to achieve the effect of flexible testing, clear depth and range, and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] By observing the color change depth and color change coverage on the pressure paper 3, the flatness of the parts and the uniformity of the stack assembly force distribution are simultaneously detected.

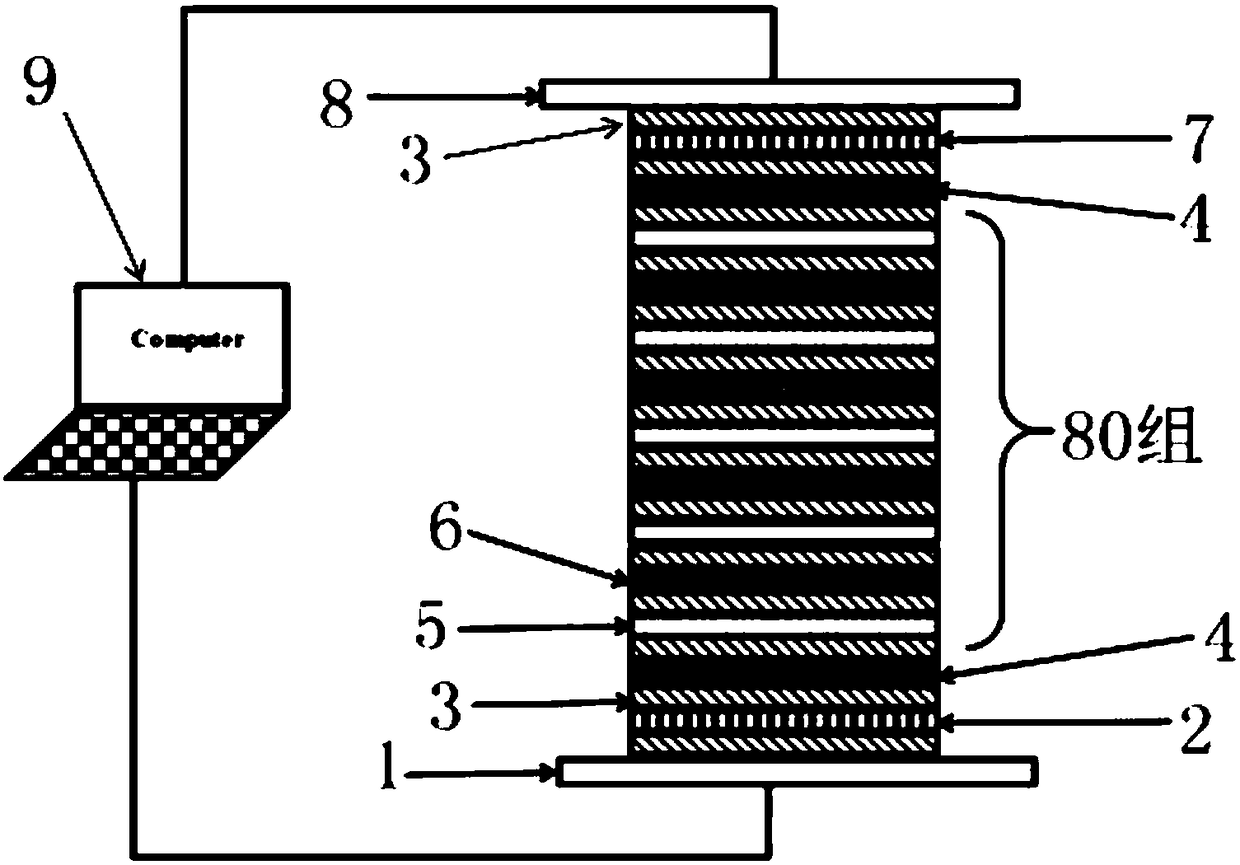

[0038] During detection, the detection system adopted includes upper platen 8, lower platen 1, control system 9, upper end plate 7, lower end plate 2, copper electrode 4, pressure paper 3, membrane electrode 6 and pole plate 5, such as figure 1 shown. Wherein the pole plate 5, the upper end plate 7, the lower end plate 2, the membrane electrode 6 and the copper electrode 4 are parts of the fuel cell stack, and the fuel cell stack is assembled by each part and the pressure paper 3 arranged between each part made. In the detection system, the fuel cell stack is arranged between the upper platen 8 and the lower platen 1 and is connected through the pressure paper 3 , and both the upper platen 8 and the lower platen 1 are connected to the control system 9 .

[0039]Among ...

Embodiment 2

[0047] The flatness of the pole plate 5 is detected by observing the depth of color change and the coverage of the color change on the pressure paper 3 .

[0048] During detection, the detection system adopted includes upper platen 8 , lower platen 1 , control system 9 , pressure paper 3 and pole plate 5 .

[0049] Among them, the pole plate 5 is a composite material pole plate with a thickness of 2mm. The pressure paper 3 adopts an ultra-low pressure type (0.6-2.5Mpa), and the structure of the pressure paper 3 adopts a double-sheet type. The length and width of the board are the same, and the thickness of the pressure paper 3 is 0.1mm.

[0050] The assembly and detection steps of the above-mentioned detection system are as follows:

[0051] (1) Cut the pressure paper 3 according to the length and width of the pole plate 5;

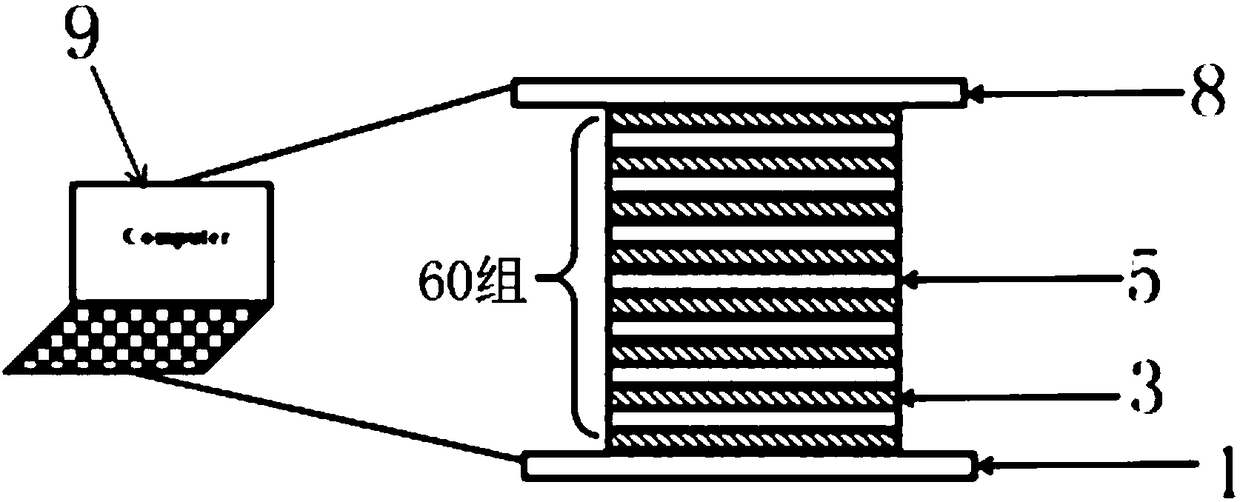

[0052] (2) According to figure 2 In the way shown, pressure paper is introduced to assemble the stack, that is, the lower platen 1 is placed first, a...

Embodiment 3

[0057] The flatness of the pole plate 5 is detected by observing the depth of color change and the coverage of the color change on the pressure paper 3 .

[0058] During detection, the detection system adopted includes upper platen 8 , lower platen 1 , control system 9 , pressure paper 3 and pole plate 5 .

[0059] Wherein, pole plate 5 is graphite pole plate, and thickness is 1mm, and pressure paper 3 adopts ultra-low pressure type (0.6-2.5Mpa), and the structure of pressure paper 3 adopts monolithic type, and the length and width of pressure paper 3 and graphite pole plate The length and width are consistent, and the thickness of the pressure paper 3 is 0.05mm.

[0060] The assembly and detection steps of the above-mentioned detection system are as follows:

[0061] (1) Cut the pressure paper 3 according to the length and width of the pole plate 5;

[0062] (2) According to figure 2 In the way shown, pressure paper is introduced to assemble the stack, that is, the lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com