Safe and quick method for precisely determining gas-liquid ratio

A measurement method and technology of gas-liquid ratio, which is applied in the field of accurate measurement of gas-liquid ratio in the safe and fast measurement of liquid-carrying gas phase, can solve problems such as gas-phase liquid carrying, affecting measurement accuracy, and bursting test tubes, so as to reduce temperature and pressure and increase measurement accuracy , Facilitate the effect of gas-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

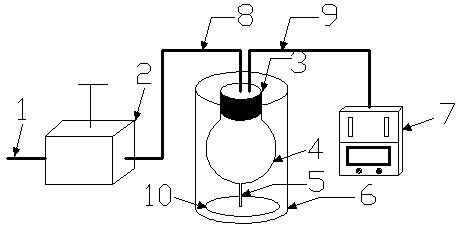

[0015] Such as figure 1 , figure 2 As shown, the gas-liquid ratio measuring device involved in the present invention is mainly composed of a pipeline 1, a flow fine-tuning valve 2, a rubber stopper 3, a buffer flask 4, a liquid meter 5, a liquid nitrogen cooling tank 6, a gas meter 7, and an air inlet line 8 , Outlet pipeline 9, base 10 composition. The liquid-carrying gas phase from the gas source enters the flow fine-tuning valve 2 through the pipeline 1. After being adjusted by the flow fine-tuning valve 2, the pressure and flow rate of the gas phase can be reduced, and a gas source with a lower pressure and a stable and slow flow rate can be obtained, which increases the safety and security of the test. accuracy. The liquid-carrying gas phase coming out of the valve enters the buffer flask 4 through the gas inlet line 8 at the rubber plug 3. Because the buffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com