A rotary UV exposure machine

A technology of exposure machine and ultraviolet light source, which is applied in the fields of optomechanical equipment, microlithography exposure equipment, photolithographic process exposure device, etc. The effect of strong performance, large processing size and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The purpose of the present invention can be achieved through the following technical solutions:

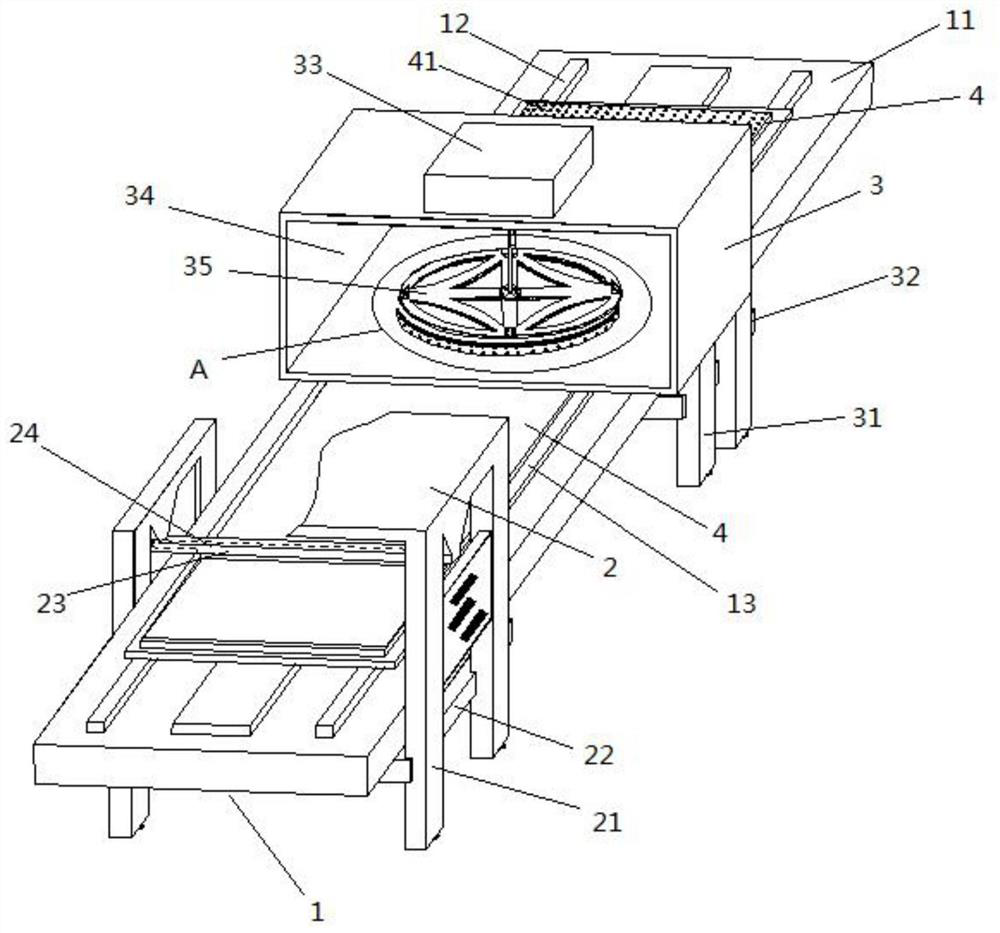

[0023] A rotary ultraviolet exposure machine, see Figure 1-2 , including transfer table 1, coating machine 2, exposure machine 3;

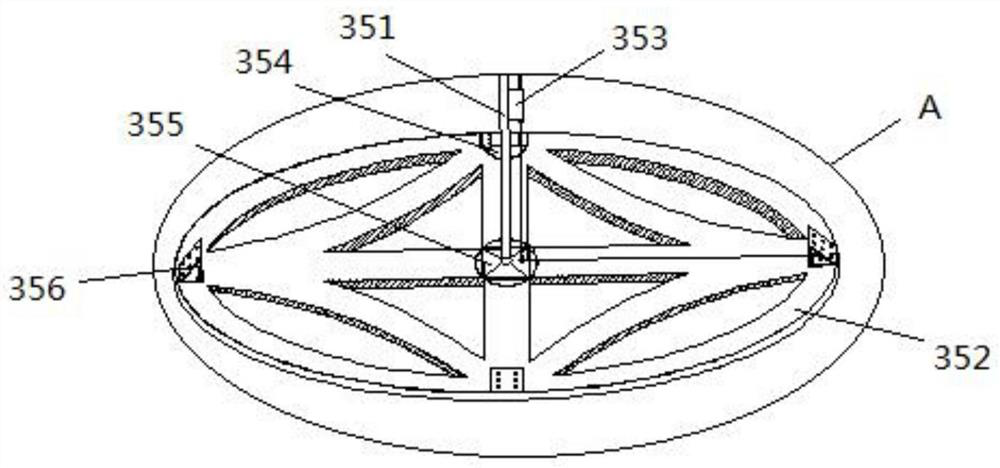

[0024] The coating machine 2 is located on one side of the exposure machine 3, and the transfer table 1 passes through the coating machine 2 and the exposure machine 3 in turn, and an ultraviolet light source generator 33 is arranged on the top of the exposure machine 3; an exposure cavity 34 is arranged in the middle of the exposure machine 3 , the exposure cavity 34 is provided with a rotary exposure device 35, and the rotary exposure device 35 is connected to the ultraviolet light source generator 33 through a light source injector 353;

[0025] The lower surface of the transfer table 1 is installed on the first base beam 22 and the second base beam 32, the first base beam 22 is arranged on the coating anti-vibration base 21 below the coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com