Novel differential- and common-mode filter inductance structure

A technology of common-mode filtering and inductance, which is applied in the field of new differential common-mode filter inductance structures, can solve the problems that filter inductance cannot be applied to high-current occasions, additionally set a magnetic conductive layer, and high production costs, and achieves easy modular design and convenient power consumption. Extended and consistent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A novel differential common-mode filter inductor structure involved in the present invention will be explained and described in detail below in conjunction with the accompanying drawings.

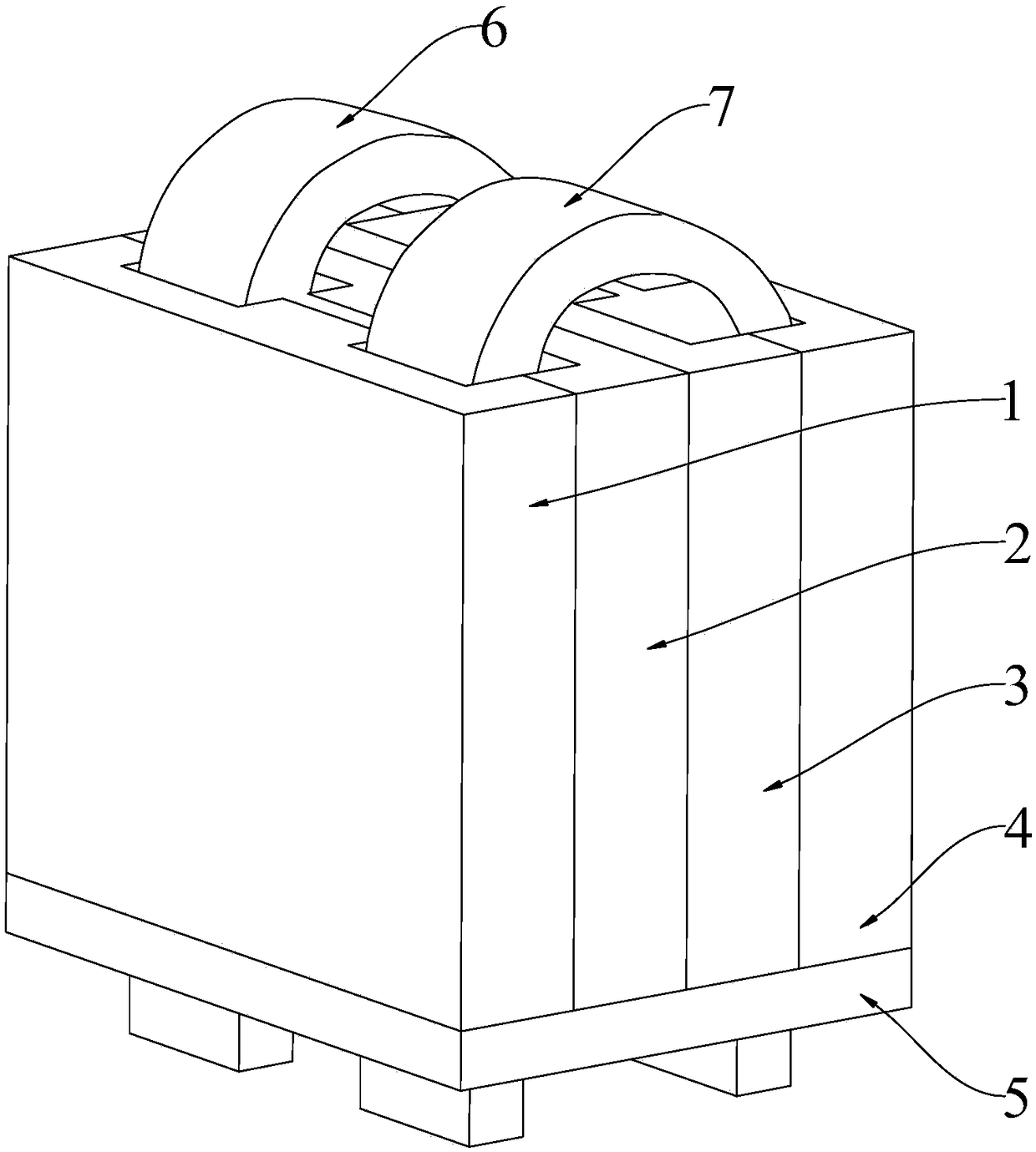

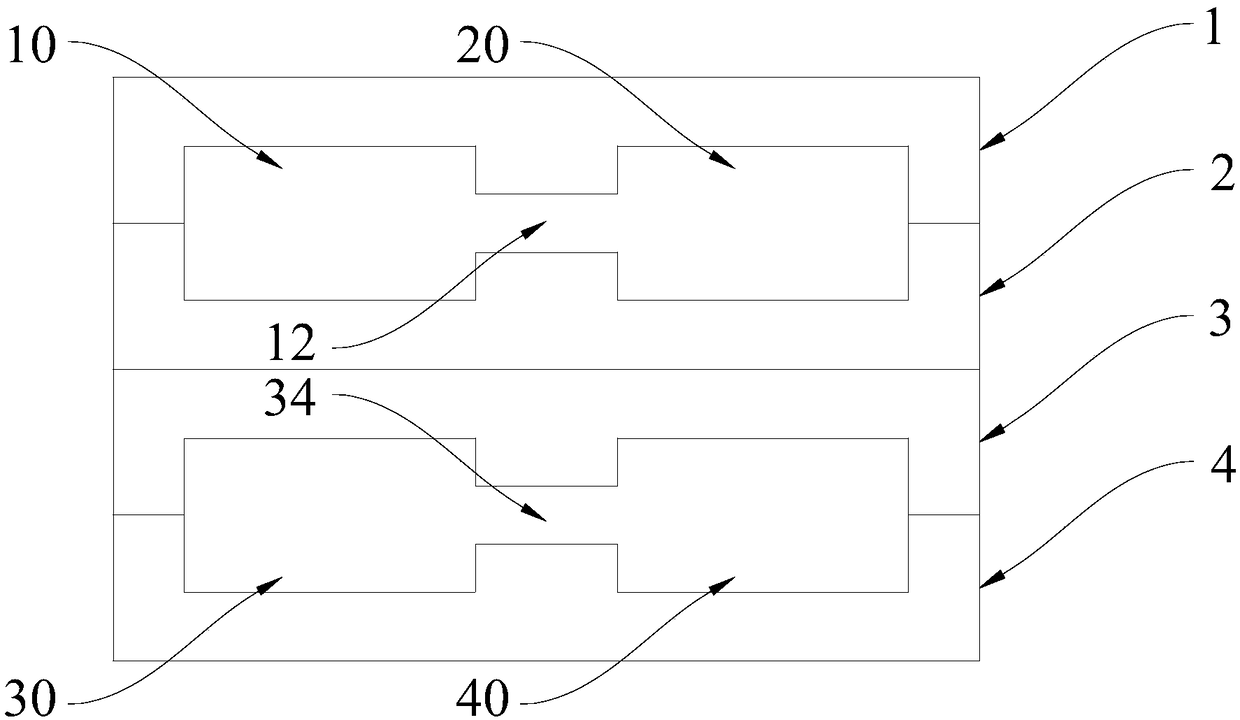

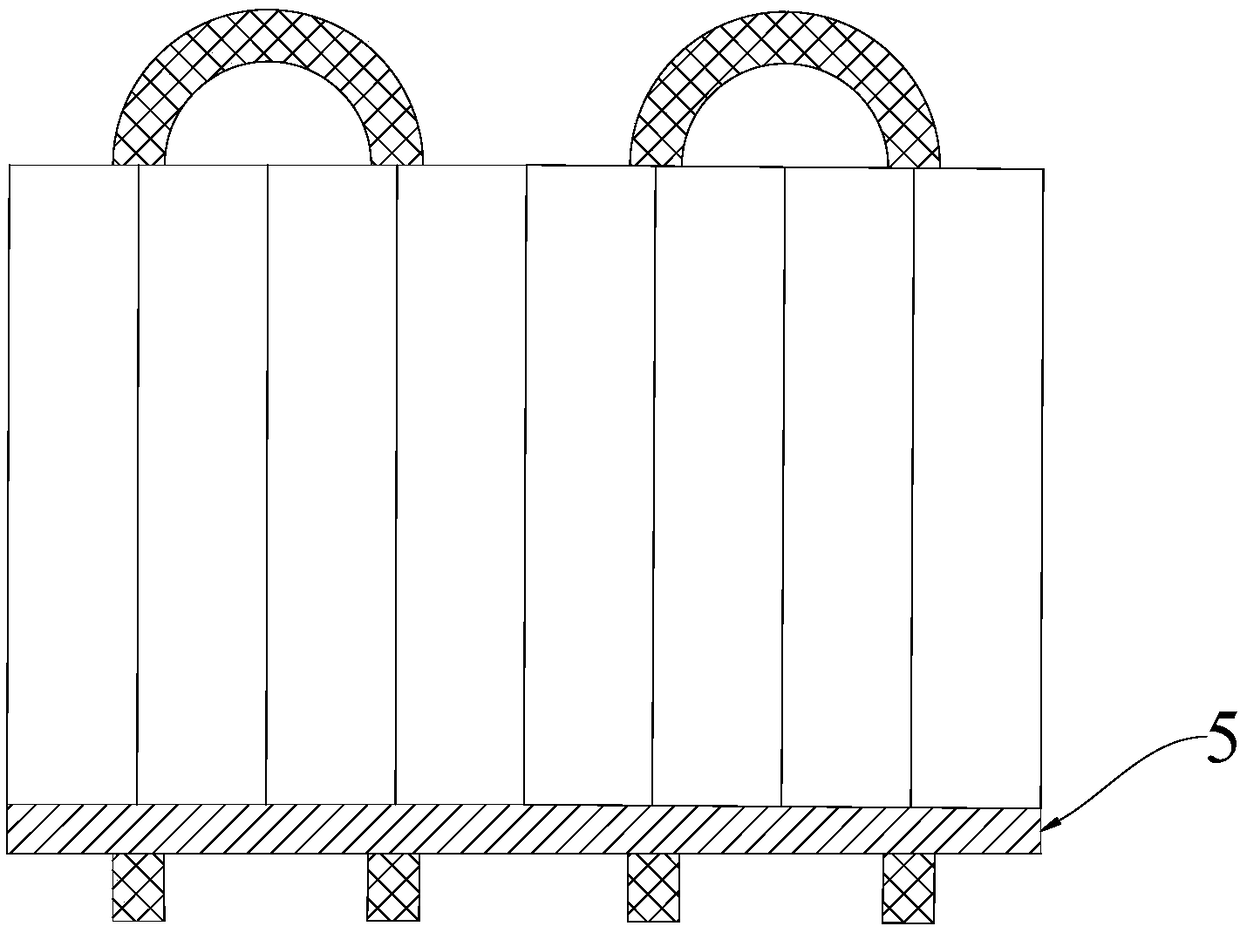

[0028] Such as figure 1 , 2 , 3, in order to solve the problems existing in existing filter inductors such as only applicable to small current occasions, poor consistency, difficulty in mass production, and high production costs, this embodiment discloses a new type of differential common-mode filter inductor structure, which can effectively solve current problems. There are many problems in the filter inductor with ring magnetic core structure, which are explained in detail as follows.

[0029] The differential common mode filter inductor structure disclosed in this embodiment includes a first magnetic core 1, a second magnetic core 2, a third magnetic core 3, a fourth magnetic core 4, a first copper strip 6 and a second copper strip 7; figure 1 As shown, the first magnetic core 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com