Floating power supply rail applicable to GaN high-speed gate driving circuit

A technology of gate drive circuit and floating power supply, applied in the direction of high-efficiency power electronic conversion, circuits, electrical components, etc., can solve the problems of insufficient dynamic range, difficult design of high-speed and high-power half-bridge gate drive circuits, and increased transmission delay of drive signals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

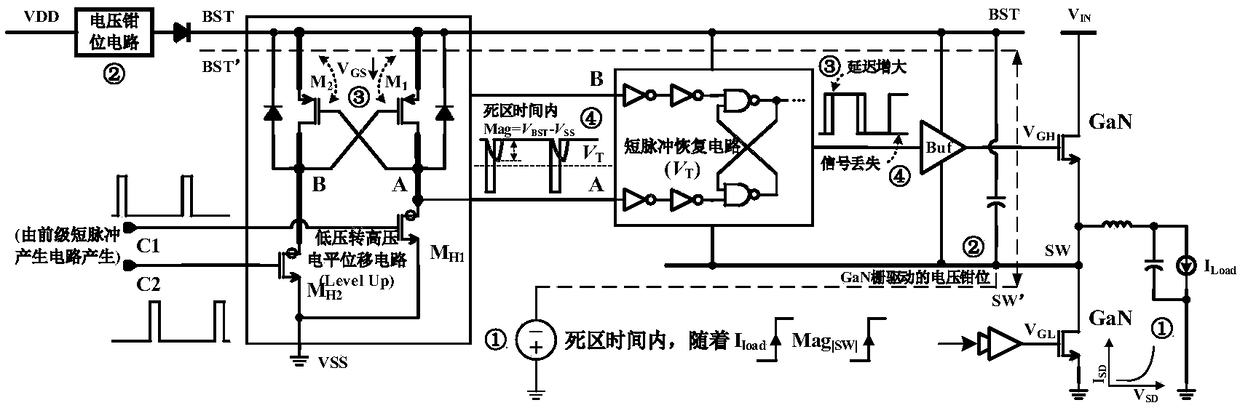

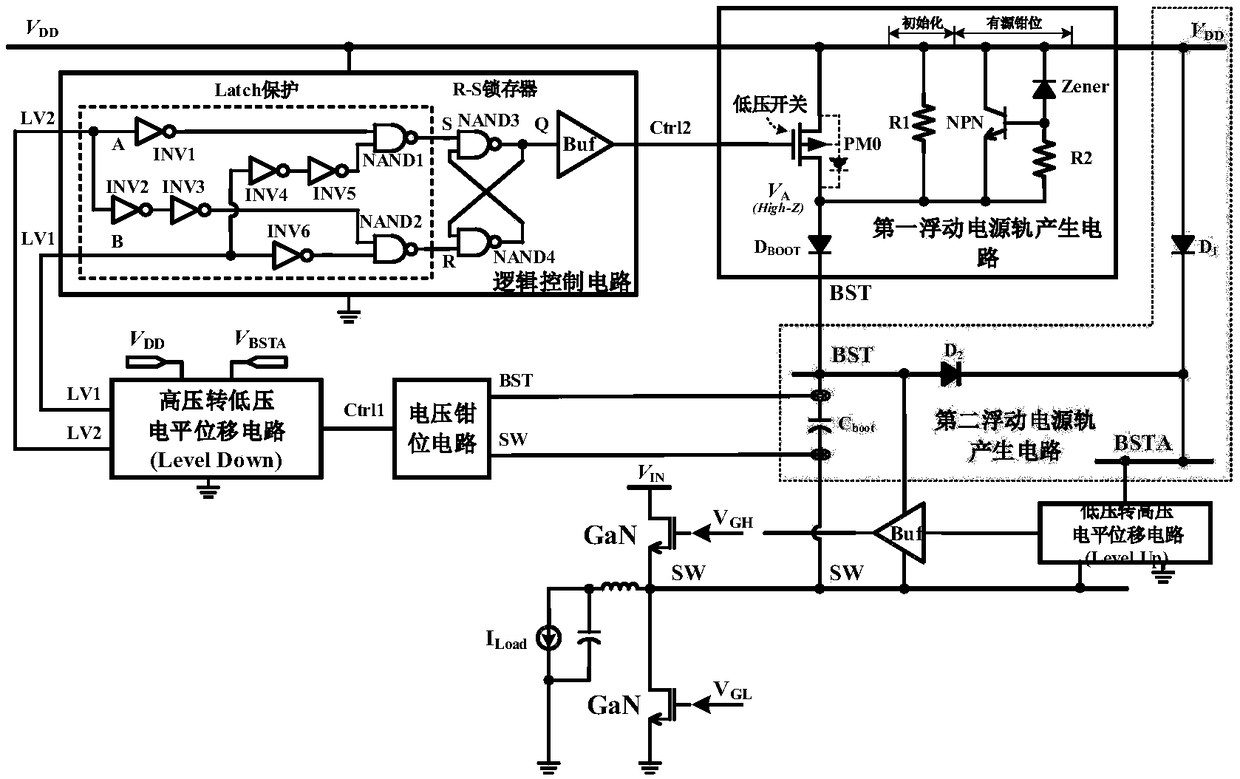

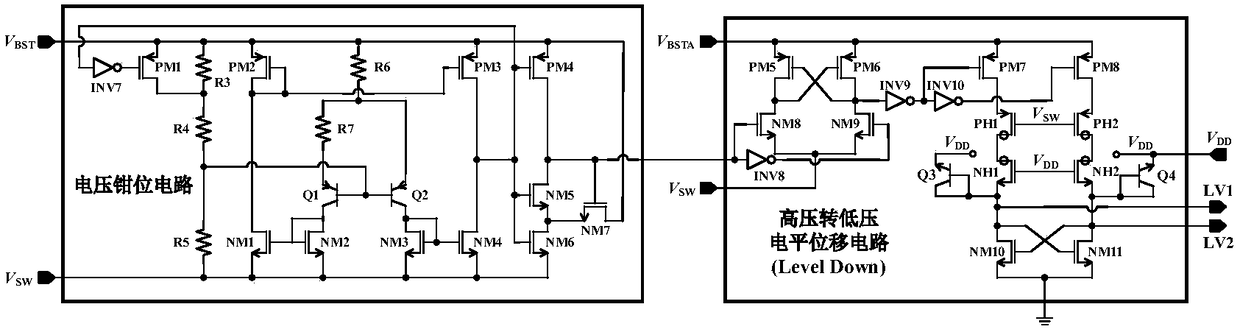

[0044] The floating power rail suitable for the GaN high-speed gate drive circuit proposed by the present invention adopts the design of double floating power rails, and the high-voltage to low-voltage level shift circuit, the voltage clamping circuit, the logic control circuit and the first floating power rail generation circuit form a closed loop. It is used to generate the first power rail BST; the two floating power rail generating circuits form an open loop and is used to generate the second power rail BSTA.

[0045] The power rails of the snubber circuit in the GaN high-speed gate drive circuit are the first floating power rail BST and the half-bridge switching node power rail SW protected by the voltage difference clamp of the bootstrap capacitor Cboot, which can protect the gate-source voltage of the GaN power switching de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com