Colored polyethylene fiber and manufacturing method for same

A technology of polyethylene fiber and manufacturing method, which is applied in the direction of single-component polyolefin rayon, textile and papermaking, textile, etc. , to achieve the effect of reducing environmental load and excellent solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

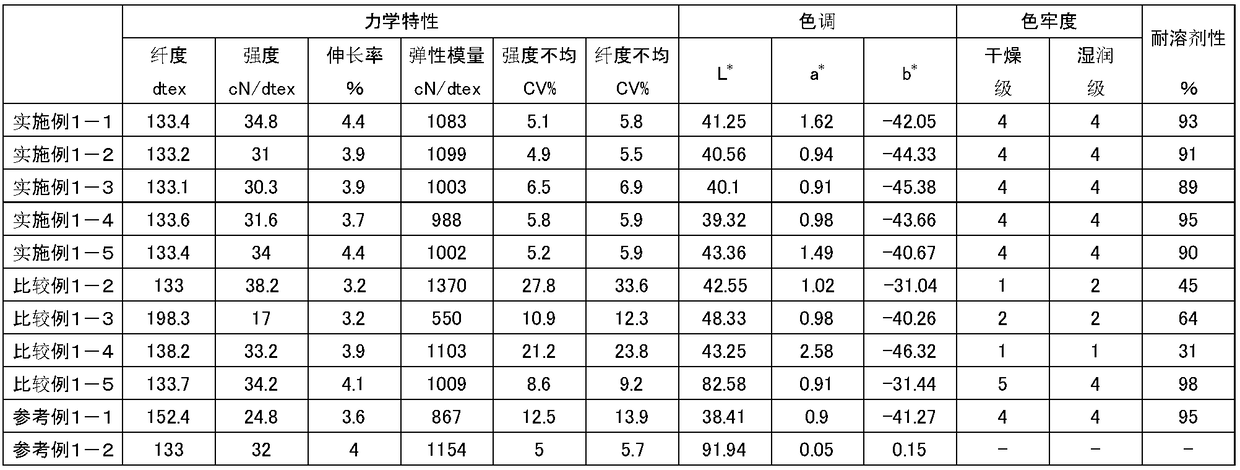

Examples

Embodiment approach 1

[0045] The colored polyethylene fiber of this embodiment is characterized in that,

[0046] (1) The L* value based on the CIE-L*a*b* chromaticity system is below 80, and the color fastness to rubbing is above grade 3 in both the dry state and the wet state; or,

[0047] (II) The solvent resistance obtained by the following measurement method is 75% or more.

[0048] [Measuring method of solvent resistance]

[0049] The colored polyethylene fibers were dipped in acetone at a concentration of 0.1 g / mL and left at room temperature for 24 hours. The transmittance in the wavelength range of 350nm to 780nm was measured using a UV-visible spectrophotometer for the acetone used to impregnate the colored polyethylene fiber and the acetone after the colored polyethylene fiber was impregnated and left to stand at 20±5°C for 24 hours , from the obtained transmittance curve, the integral value of the transmittance in the above-mentioned wavelength region was obtained, and the solvent res...

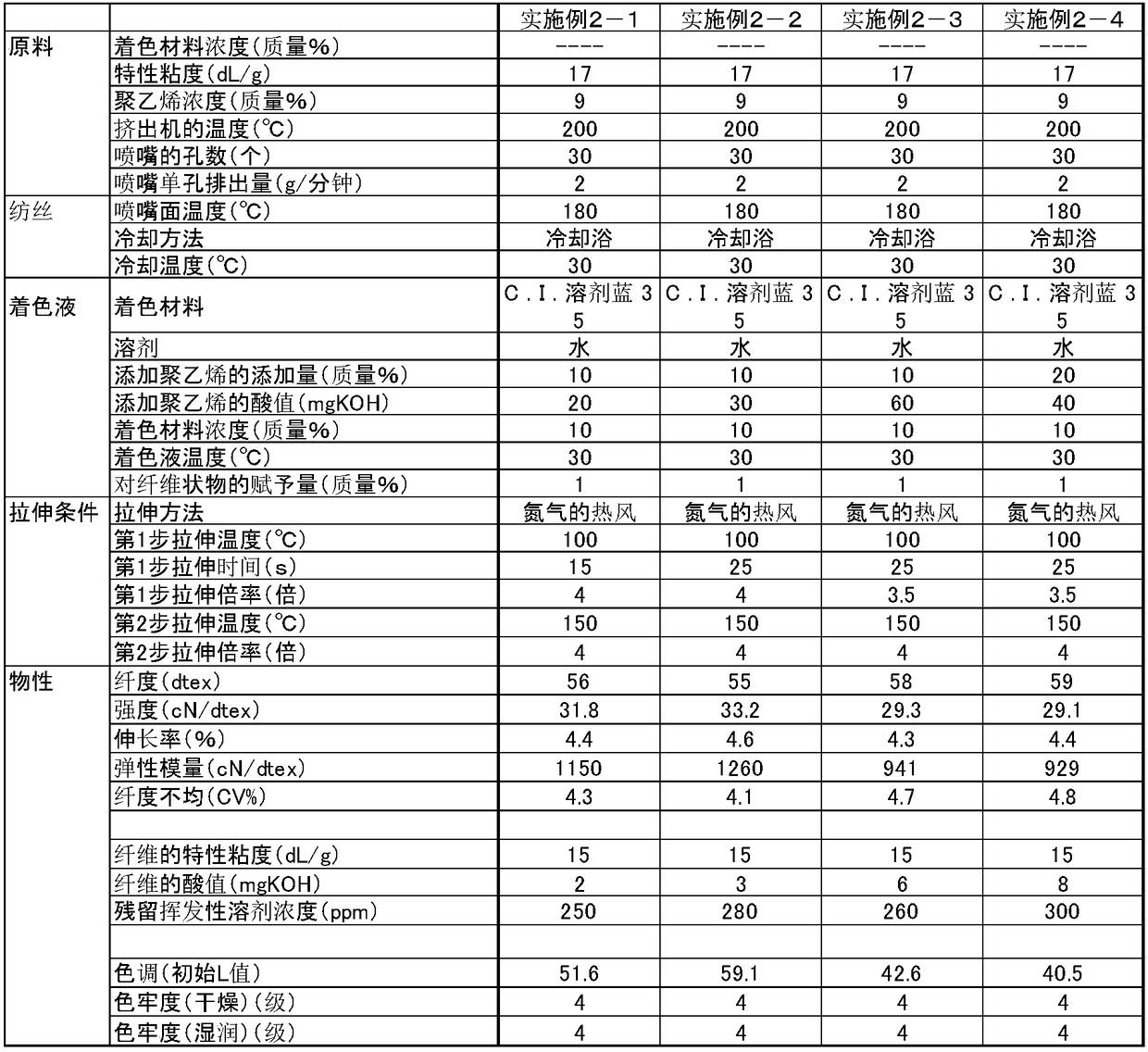

Embodiment approach 2

[0107] The colored polyethylene fiber of this embodiment is characterized in that,

[0108] Based on the CIE-L*a*b* chromaticity system, the L* value is below 80, the color fastness to rubbing is above grade 3 in both dry and wet states, and the acid value is above 0.1mgKOH / g and 50mgKOH / g or less.

[0109] The colored polyethylene fiber of this embodiment is colored in a dark color, and the L* value obtained when the colored polyethylene fiber or a processed product obtained from the colored polyethylene fiber is measured by the CIE-L*a*b* color difference measurement method is Below 80. The smaller the L* value, the darker the polyethylene fiber is. Therefore, the L* value must be 80 or less, preferably 75 or less, more preferably 70 or less, still more preferably 65 or less. In addition, the lower limit of L* value is not specifically limited.

[0110] The colored polyethylene fiber of this embodiment is excellent in color fastness to rubbing. More specifically, the c...

Embodiment approach 3

[0147] The colored polyethylene fiber of this embodiment is characterized in that,

[0148] The L* value based on the CIE-L*a*b* colorimetric system is 80 or less, the color fastness to rubbing is grade 3 or higher in both the dry state and the wet state, and contains 0.4% to 5.0% of HLB A surfactant having a value (Hydrophile-Lipophile Balance) of 7.0 or more and 14.0 or less.

[0149] The colored polyethylene fiber of this embodiment is colored in a dark color, and the L* value obtained when the colored polyethylene fiber or a processed product obtained from the colored polyethylene fiber is measured by the CIE-L*a*b* color difference measurement method is Below 80. The smaller the L* value, the darker the polyethylene fiber is. Therefore, the L* value must be 80 or less, and the L* value is preferably 75 or less, more preferably 70 or less, even more preferably 65 or less. In addition, the lower limit of L* value is not specifically limited.

[0150] The colored polyeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com