Preparation method of ion-imprinted blended membrane

A technology of ion imprinting and blended membranes, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of reducing the adsorption capacity and adsorption rate of imprinted blended membranes, template molecules are not easy to elute, etc., and achieve fast adsorption rates , large saturated adsorption capacity and high affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

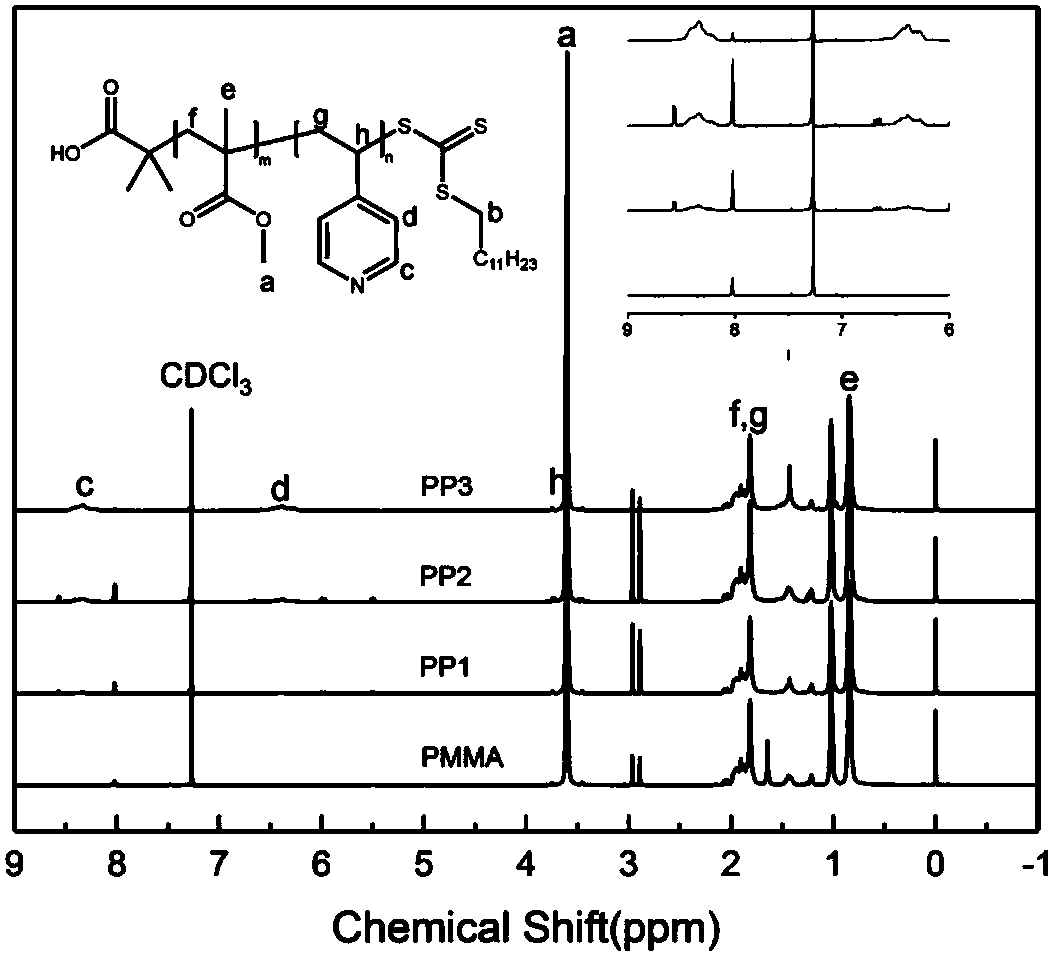

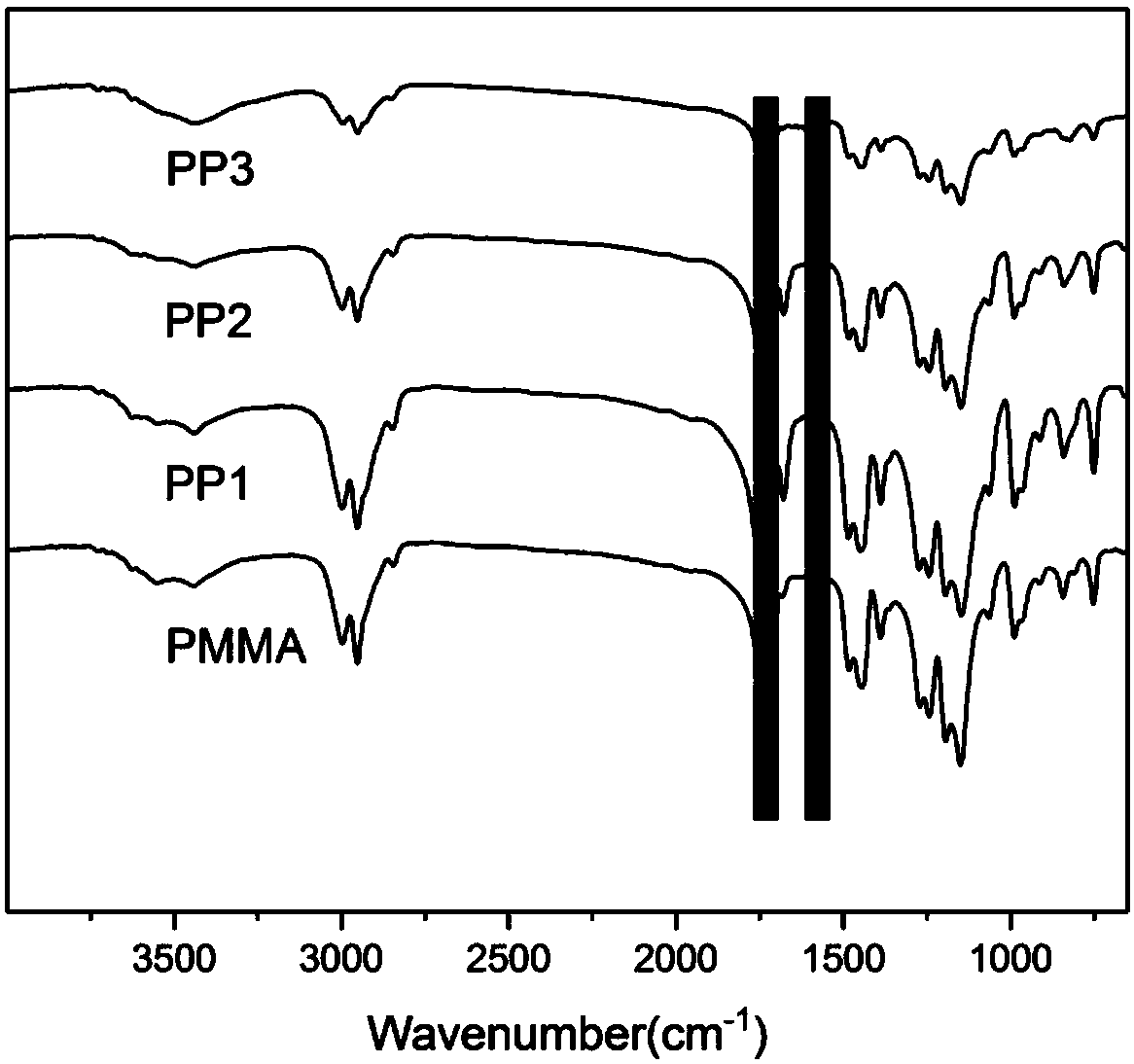

[0050] Methyl methacrylate was removed from the polymerization inhibitor through a flash chromatography column filled with basic alumina before use, and sealed and stored at 2°C in the dark; azobisisobutyronitrile was reconstituted in absolute ethanol before use. Crystallized three times, sealed and stored at 2°C, protected from light; polyvinylidene fluoride was vacuum-dried at 90°C for 24 hours to remove water before use.

[0051] Synthesis of trithioesters: RSH (n-dodecanethiol) (48mL, 40.38g, 0.2mol), acetone (160mL) and methyl trioctyl ammonium chloride (phase transfer agent) (3.6mL, 3.2g, 0.008mol) into a 1L three-necked flask, cooled to 10°C and protected with nitrogen. After slowly adding 50% NaOH solution (16.7g, over 20min) dropwise, continue to stir for 15min, then add a solution of acetone (25mL, 20g, 0.3mol) dissolved with CS2 (12mL, 15.2g, 0.2mol) over a period of over 20min. 20min, after the solution turned red for 10min, CHCl3 (24mL, 35.6g, 0.3mol) was added o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com