Sequencing batch anaerobic dry fermentation apparatus and method

A fermentation device and anaerobic drying technology, which is applied in the field of anaerobic dry fermentation, can solve the problems of low efficiency of feeding and discharging materials, and achieve the effects of increasing efficiency, improving feeding and discharging efficiency, and increasing raw material utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

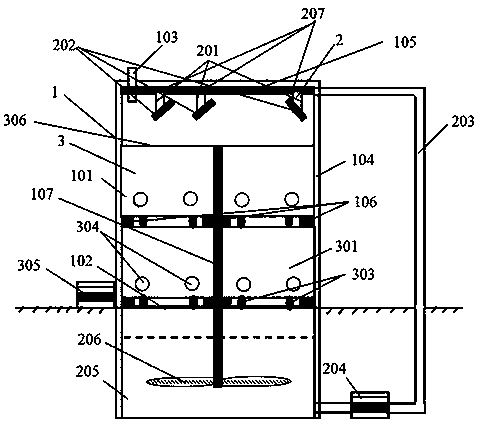

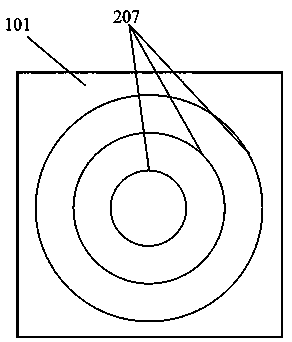

Embodiment 1

[0040] There are three circular orbits 207, which are arranged in concentric circles. Straw, livestock and poultry manure mixed materials (solid content 30%, dry matter material ratio 6:4, inoculum ratio 40%) are mixed well in advance, outside the reactor, usually in the raw material pretreatment field, with a forklift Load the material into the material reaction vehicle and push it into the reactor with a cart, so that the material reaction vehicle is stuck on the receiving steel plate. When the material reaction vehicle is installed in the lower part, start the conveyor belt trough to lift the lower material reaction vehicle to the upper layer , And then enter a number of material reaction vehicles according to the same method, and finally make the material reaction vehicles fill the entire material reactor and start fermentation. Start the spraying equipment after fermentation starts. (2) The spraying frequency is 1 spray every 4 hours, 10 min each time. Adjust the spray flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com