Bell-type furnace for high-temperature heat treatment of metal band roll and application of bell-type furnace

A high-temperature heat treatment and metal strip technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of watermark formation, high heat treatment temperature, and exceeding the working temperature range of circulating fans, etc., to reduce energy consumption, accelerate heating and cooling The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

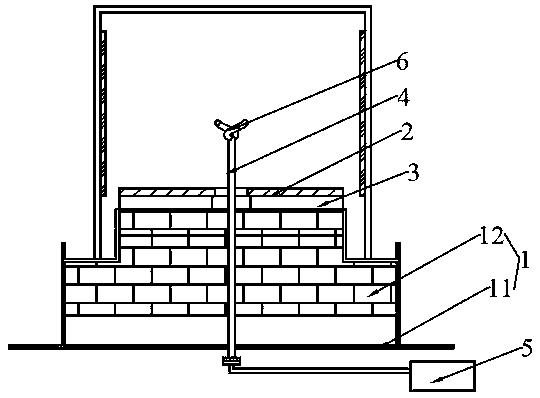

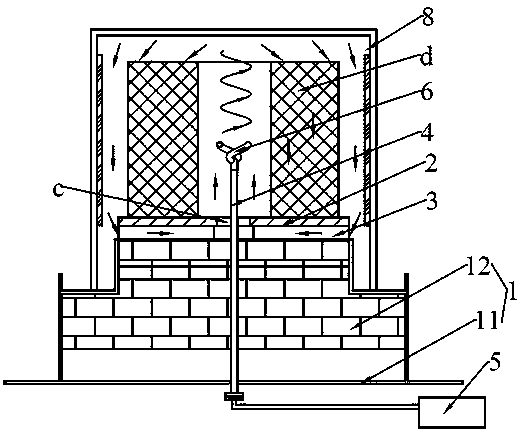

[0039] Such as Figure 1-4As shown, the bell-type furnace for high-temperature heat treatment of metal strip coils in Example 1 includes a furnace base 1, a furnace plate 2 and a furnace cover 8. Several raised parts a are arranged on the top of the furnace base 1 to form a raised layer 3, and the furnace plate 2 It is arranged on the top of the protruding layer 3, and there is an air guide channel b between several protruding parts a, and a vent hole c is arranged in the center of the furnace plate 2, and the air guide channel b communicates with the vent hole c; the furnace cover 8 is sealed Set on the furnace platform 2 on the outer edge of the furnace plate 2;

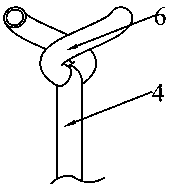

[0040] The hearth 1 is embedded with a vertical protective gas pipe 4, which communicates with the gas source 5, and the top of the protective gas pipe 4 is connected with at least two branch pipes 6, and the branch pipes 6 are inclined upward and diverge in a spiral shape with the same rotation direction. The bra...

Embodiment 2

[0046] Such as Figure 5-6 As shown, the difference between embodiment 2 and embodiment 1 is that the number of branch pipes is 3;

[0047] The branch pipe 6 includes a transition pipe section 61 connected end to end and a spiral pipe section 62, the spiral pipe section 62 is a cylindrical helical pipe, one end of the transition pipe section 61 is connected to the protective air pipe 4, and the central axis of the protective air pipe 4 and the central axis of the transition pipe section 61 are clamped The obtuse angle is 110°. The cylindrical helical tube can also be a conical helical tube. In Embodiment 2, the obtuse angle formed by the central axis of the protective gas pipe 4 and the central axis of the transition pipe section 61 can be enlarged to 150°. The transition pipe section 61 is a straight pipe.

[0048] The helix angle of the spiral pipe section 62 is 30-60°.

[0049] In Embodiments 1 and 2, the seal between the protective gas pipe 4 and the hearth 1 is filled...

Embodiment 3

[0053] Such as Figure 7-10 As shown, the difference between embodiment 3 and embodiment 2 is that the top surface of the furnace plate 2 is divergently provided with several ventilation grooves 7, and the two ends of the ventilation grooves 7 protrude from the ring contact area of the metal strip coil d of the furnace plate 2 Edge and Outer settings.

[0054] Ventilation slot 7 is arc-shaped, and the direction of rotation of the inner arc on the top surface of furnace plate 2 is the same as that of the spiral pipe section.

[0055] The furnace base 1 includes a base plate 11 and a furnace base body 12 fixedly arranged on the base board. The shielding gas pipe 4 is penetrated through the base board 11 and the furnace base body 12. The shielding gas pipe 4 is welded and sealed to the bottom surface of the base board 11. The bottom ends of the shielding gas pipe 4 are sequentially Connect with the air source 5 through flanges, conduit flanges, and conduits.

[0056] The notc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com