Tunnel lining structure with combined action of high-strength pre-pressing anchor rods and fluid inclusions

A combined action and inclusion technology, applied in tunnel linings, tunnels, shaft linings, etc., can solve the problems affecting the concrete curing cycle, personnel and property losses, delaying the progress of the project, etc., to save the cost of purchasing expansion equipment and shorten the construction period. , Reduce the effect of bursting and shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

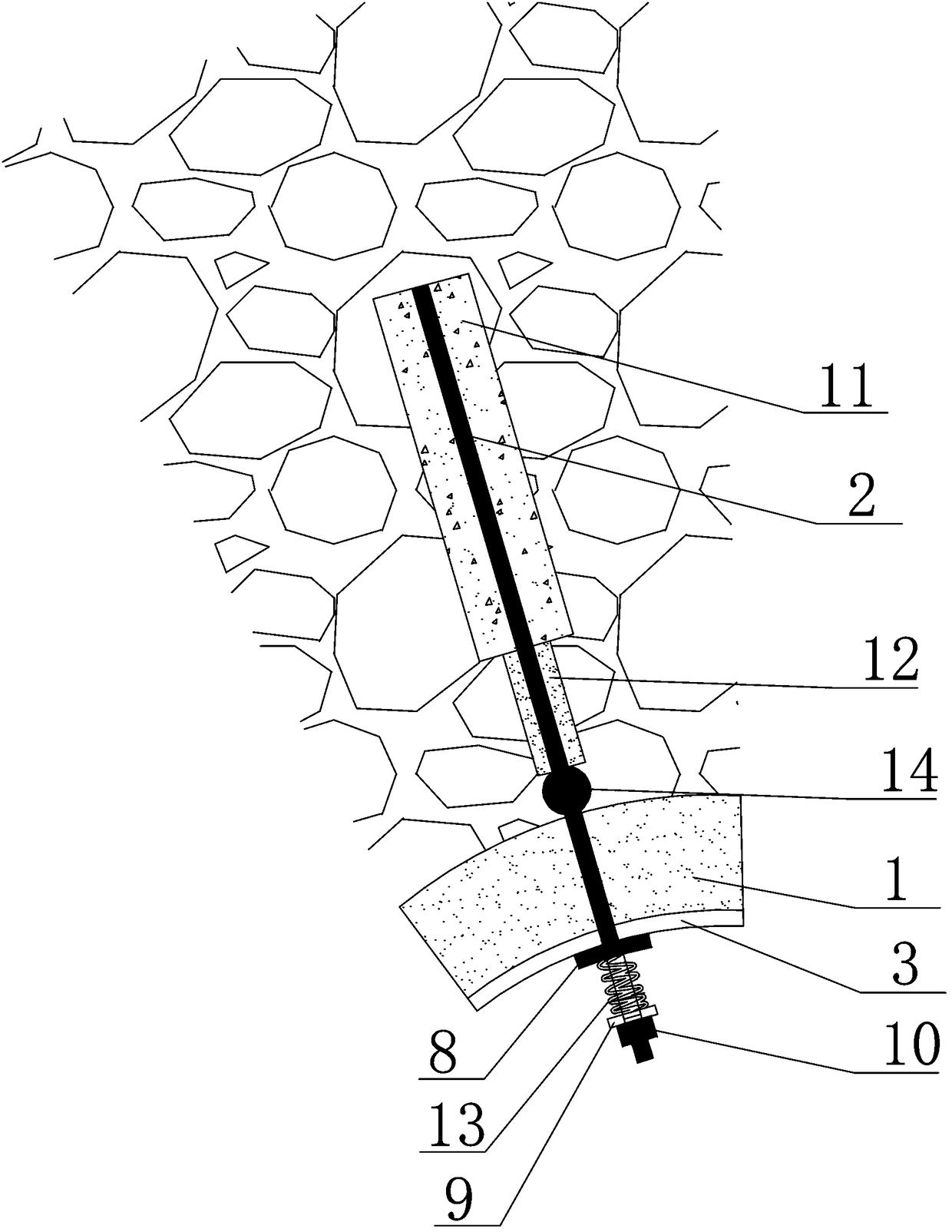

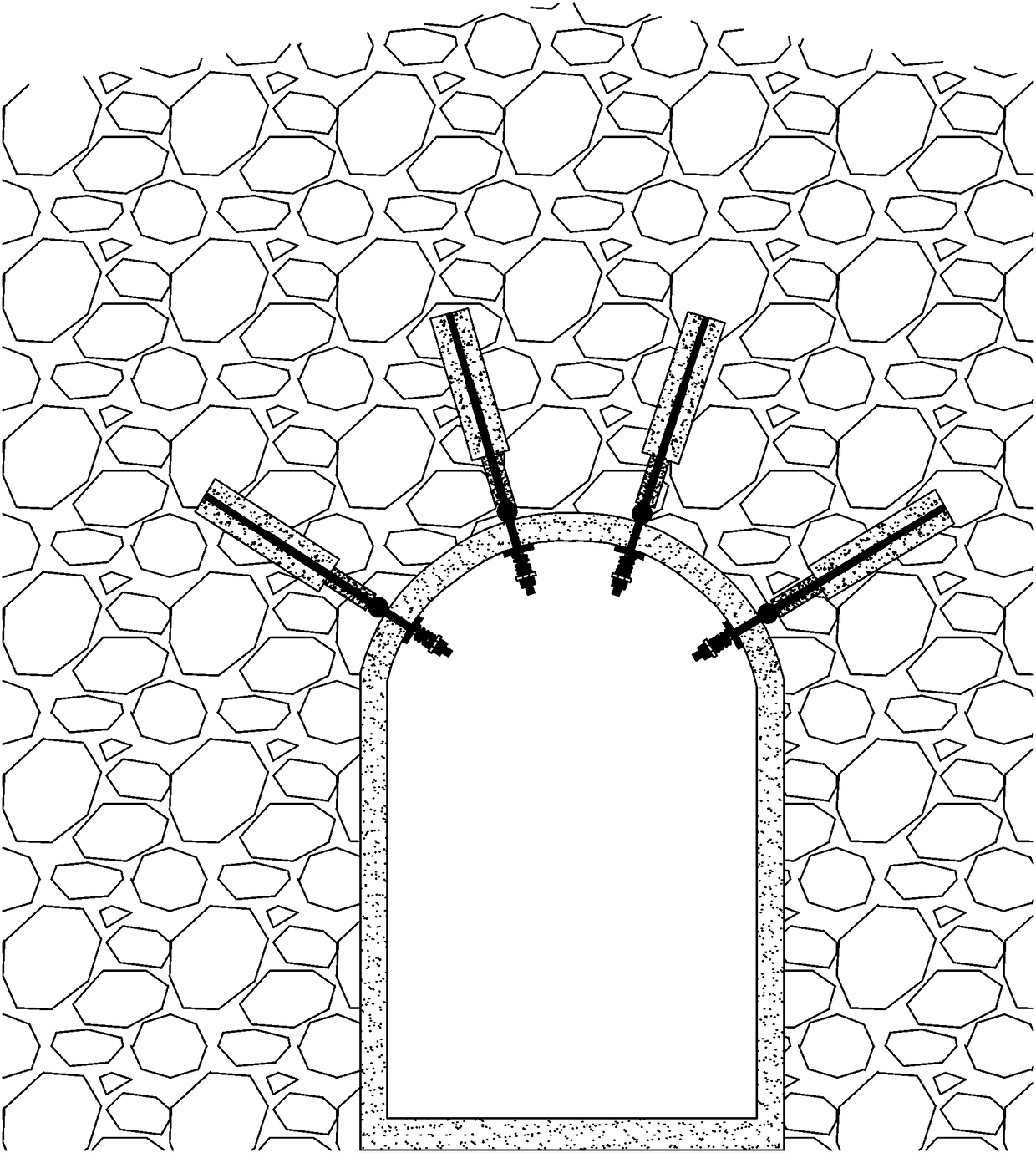

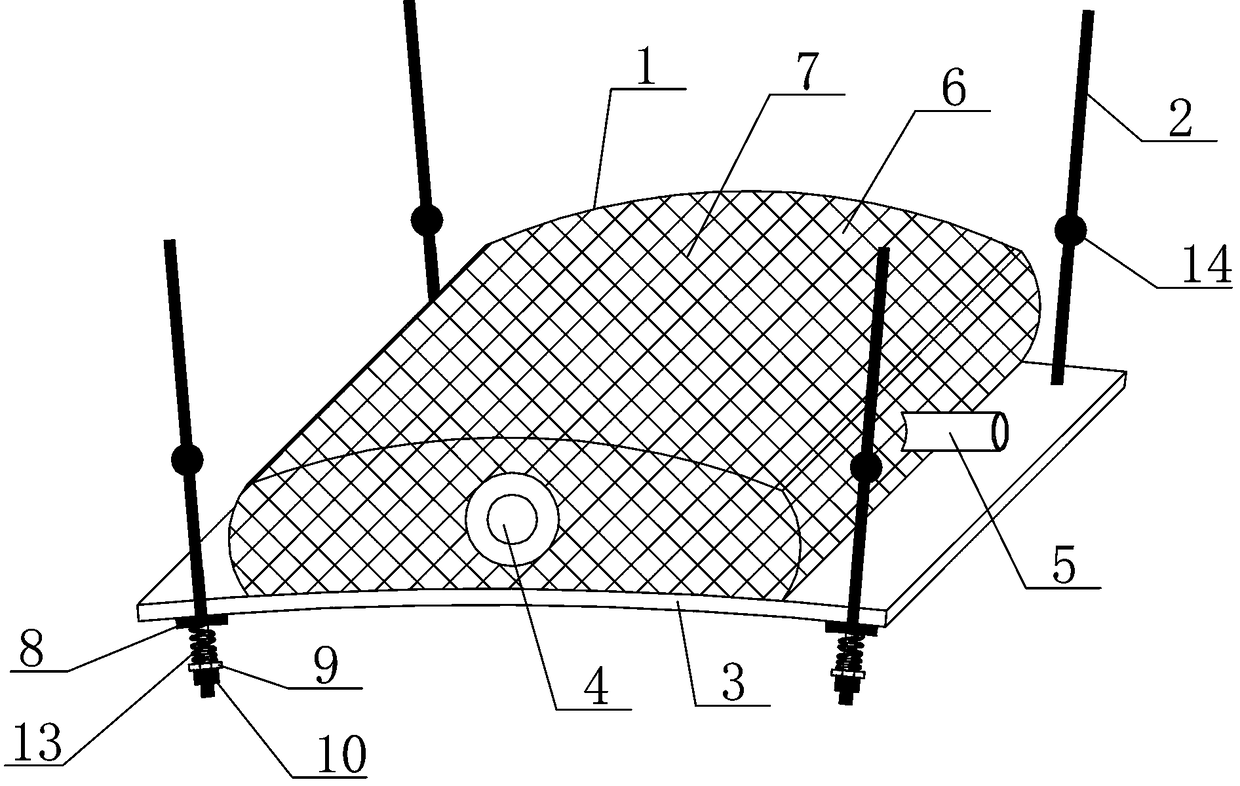

[0031] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0032] Such as Figure 1~3 , a tunnel lining structure combined with high-strength preloaded anchors and fluid inclusions, which includes fluid inclusions in contact with the tunnel surrounding rock, high-strength preloaded anchors, and reinforced concrete linings, and the fluid inclusions are made of high-strength preloaded The pressure anchor and the reinforced concrete lining are fixed around the surrounding rock of the tunnel, and a pressure relief valve is provided on one side of the fluid inclusion, and the fluid inclusion is provided with a circular connection port connected with other inclusions; the fluid inclusion A reinforced concrete lining is provided on the side of the body facing the tunnel, and the reinforced concrete lining is fixed with a high-strength preloaded anchor rod, and two adjacent fluid inclusions are detachably assembled and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com