Ethyl maltol fluidizing drying device

An ethyl maltol and fluidized drying technology, which is applied in the directions of drying gas arrangement, drying solid materials, and drying goods processing, can solve the problems of waste of ethyl maltol, increase enterprise cost, increase labor burden, etc., and achieve cost saving , The effect of reducing material agglomeration and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

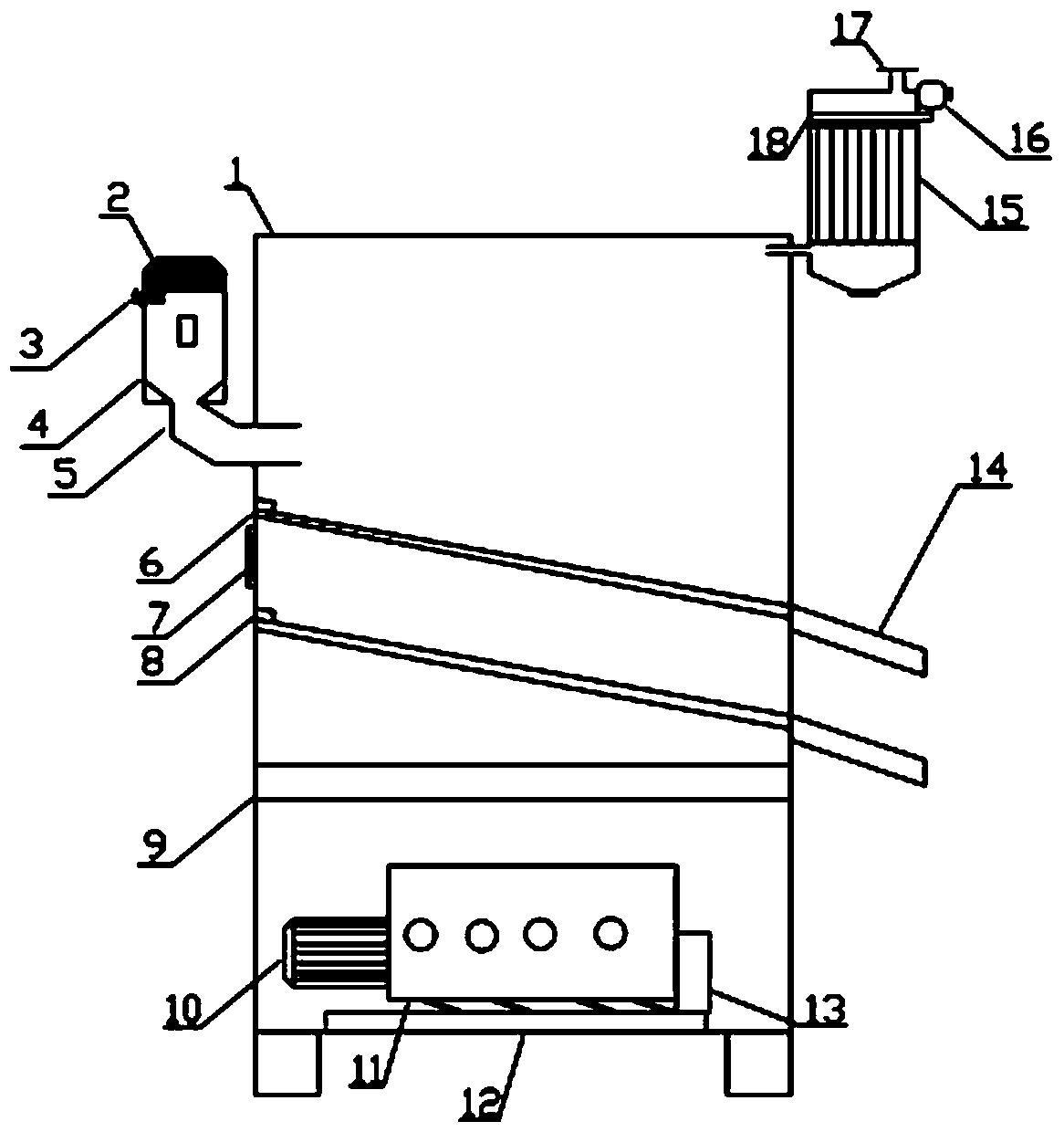

[0015] The invention provides a fluidized drying device for ethyl maltol, comprising a housing 1, a vacuum feeder, a cloth bag collection device, a drying device and a grading device, the side wall of the housing is provided with a vacuum feeder, The top is provided with a cloth bag collecting device, the drying device and the classifying device are located inside the housing and the drying device is located below the classifying device, and the classifying device includes several fluidized bed bodies 6, one end of the fluidized bed body 6 It is fixedly connected with the side wall of the shell 1, and the other end is connected with the discharge port 14 provided on the side wall of the shell. The fluidized bed body 6 is inclined and the angle formed with the horizontal plane is 30°. The height of one end of the side wall of the connecting shell 1 along the vertical plane is higher than that of the end connected with the discharge port 14, and a vibrating device 8 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com