Sampling method for quality inspection of primary side end sealing partition plate of nuclear power steam generator

A steam generator and quality inspection technology, applied in sampling devices and other directions, can solve problems such as insufficient verification of the overall quality of the plate and manufacturing stability, and achieve the effect of reducing inspection costs, reducing inspection items, and ensuring repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0046] Such as Figure 1 to Figure 18 As shown, a sampling method for the quality inspection of the primary side head partition plate of a nuclear power steam generator, the treatment process of the primary side head partition plate includes rough machining, solid solution treatment and special heat treatment in sequence. Among them, solution treatment is used to improve the performance of the primary side head separator in terms of strength, toughness or microstructure. The special heat treatment is TT (Thermal Treatment) heat treatment process, which is mainly used to improve the distribution of carbides and improve the corrosion resistance of the primary side head separator.

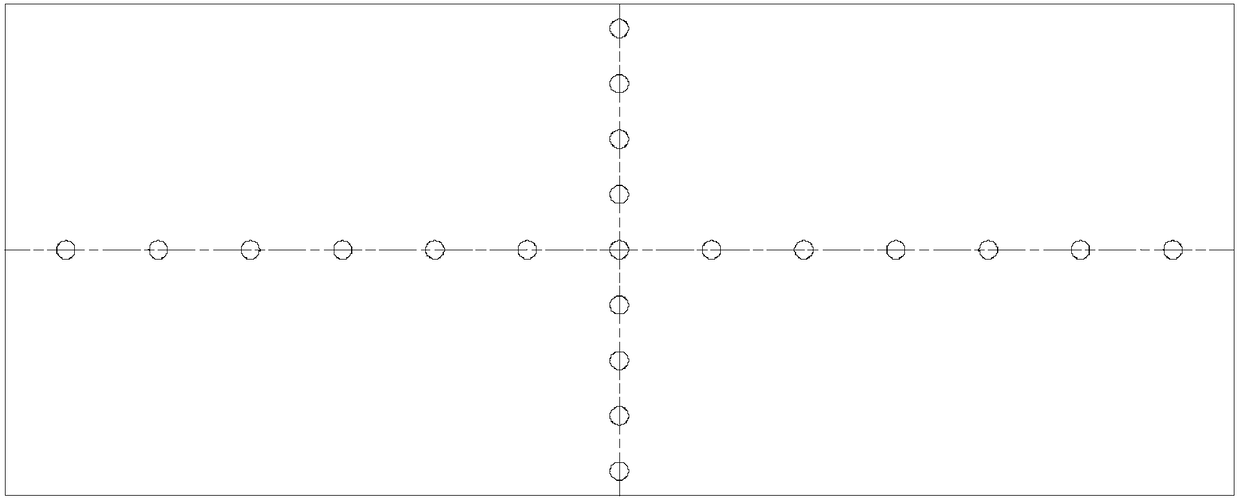

[0047] Such as Figure 1 to Figure 3 Shown is a schematic diagram of the test point distribution of the chemical composition uniformity of the primary side head partition pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com