X-ray fluorescence thin layer mass thickness measurement system and method based on reference element

A technology of reference elements and mass thickness, which is applied in the field of X-ray fluorescence analysis, can solve the problems of instrument performance fluctuation and influence on measurement results, and achieve good oxidation resistance and photostability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

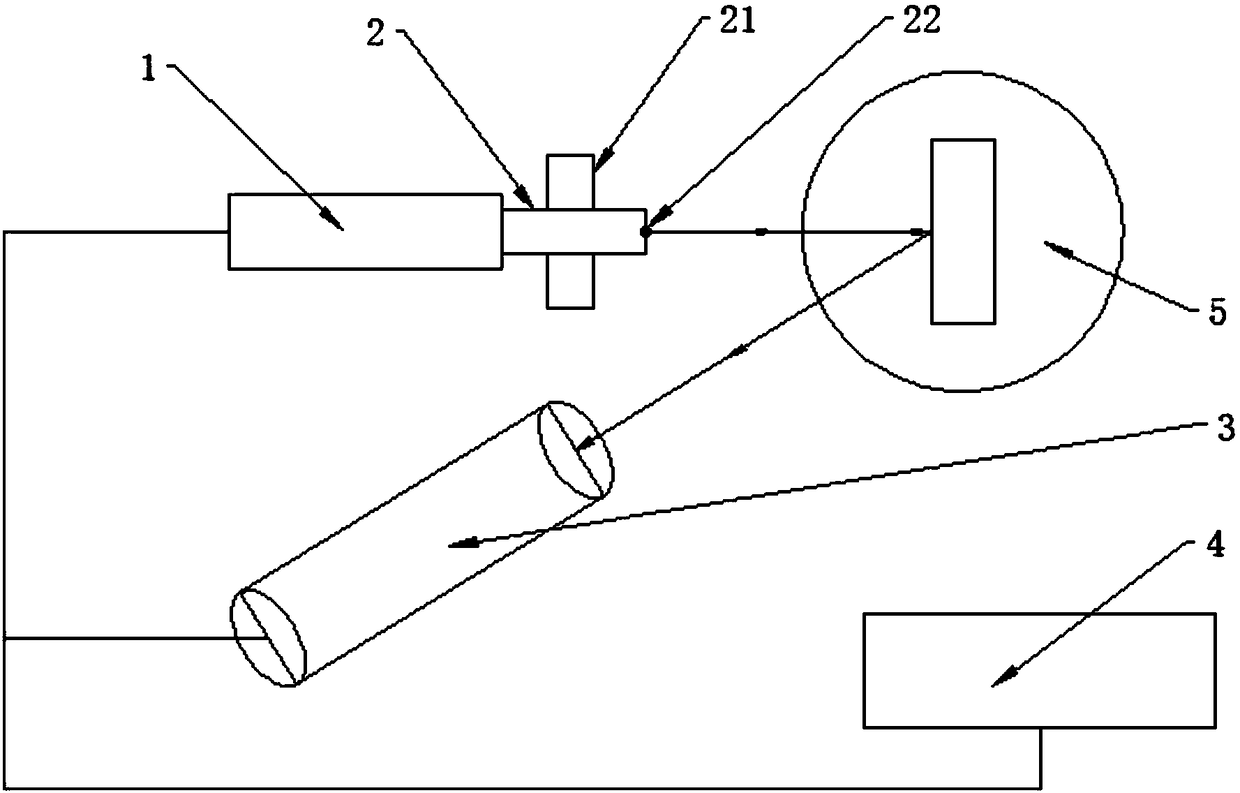

[0053] see figure 1 , the present embodiment provides a X-ray fluorescence thin-layer quality and thickness measurement system based on reference elements, including a portable low-power X-ray tube 1, a collimator 2, a shielding plate 21, a detector 3, a substrate, a sample stage 5 and The control terminal 4 is electrically connected with the X-ray tube 1 and the detector 3 respectively.

[0054] The collimation tube 2 and the shielding plate 21 are made of stainless steel, the length of the shielding plate 21 is 250mm, and the mass thickness is 10mm. The input end of the collimator 2 is connected with the exit port of the X-ray tube 1, and the output end is provided with a tungsten pinhole 22 . The tungsten pinhole 22 is used to limit the excitation rays emitted by the X-ray tube, collimate the X-rays emitted by a small divergence angle, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com