Large-power island special power supply module cooling device and temperature control method thereof

A temperature control method and technology of special power supply, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as equipment aging failure, harsh island environment, large temperature difference between day and night, etc. Heat dissipation efficiency, fast dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

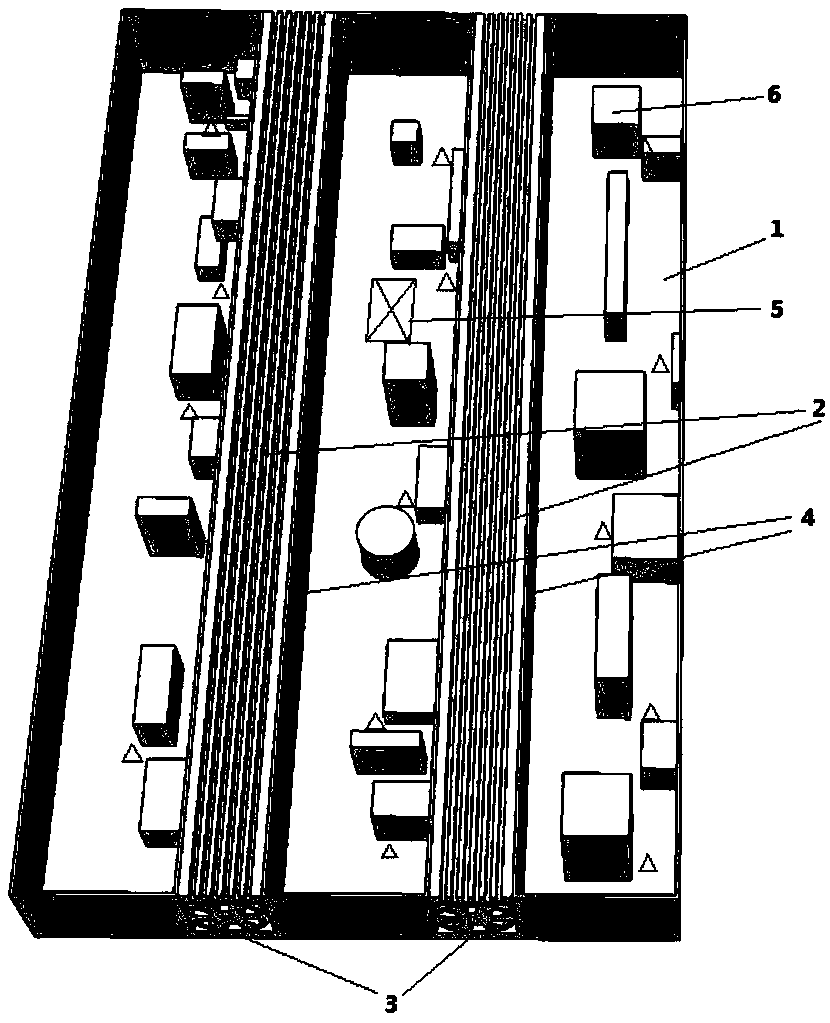

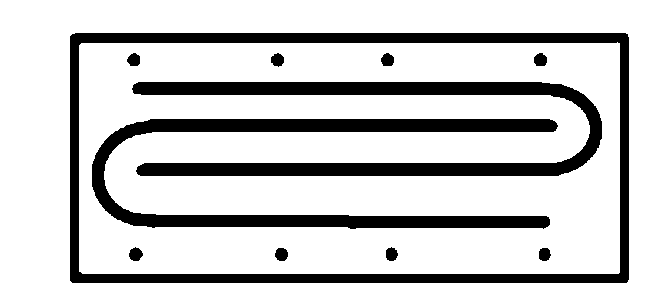

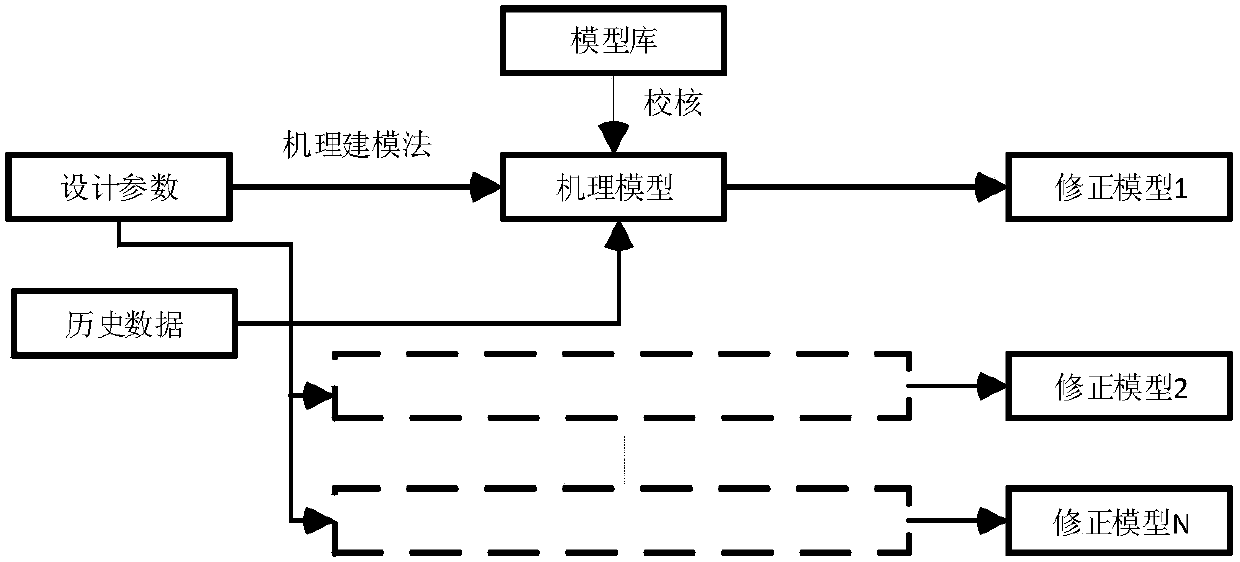

[0030] The module unit of the present invention uniformly adopts the cavity formed by the air duct, the top cover of the power supply, and the side panel as the package to form a multi-face heat dissipation structure. The contact surface between the air duct and the power device is embedded with a heat soaking pipe to disperse the heat from the point heat source and reduce the diffusion thermal resistance, improving the heat dissipation efficiency. The cooling air is quickly conveyed through the cooling air channel inlet and outlet fans, so that the conducted heat can be quickly transferred to the outside of the module through cold and heat exchange, so as to achieve the purpose of overall heat dissipation of the power module. A thermal coupling model is established based on historical data and equipment characteristics. The control part of the device includes a temperature monitoring module and a main control module, which cooperate with the constructed model to realize model ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com