Three-level production planning system for steel-making enterprises

A production planning and enterprise technology, applied in manufacturing computing systems, calculations, instruments, etc., can solve problems such as inability to adjust, inability to match the company's consistent system, and no accurate time concept, to reduce water failure accidents and control the production rhythm. , the effect of high operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

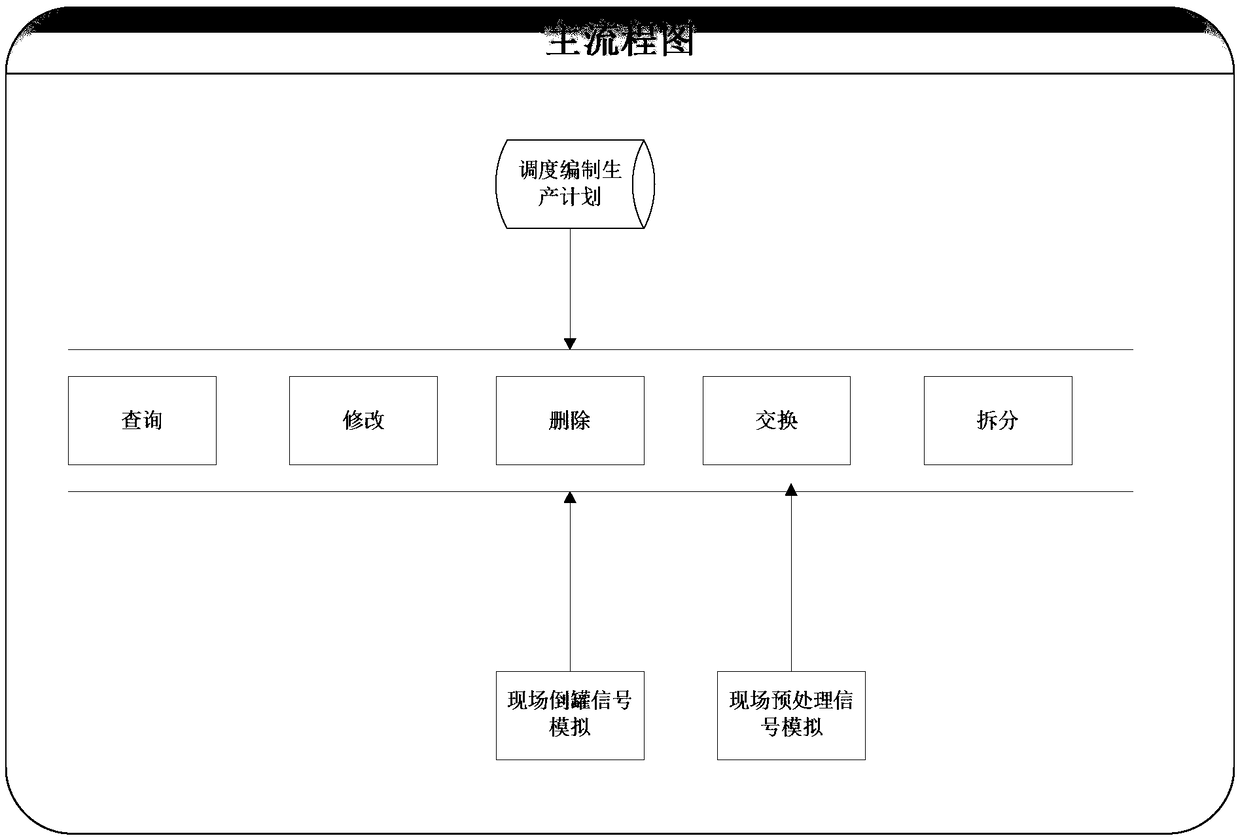

[0053] A three-level production planning system for a steelmaking enterprise of the present invention comprises the following steps:

[0054] Use the manufacturing execution system to establish a three-level production planning system and create a data table for saving data and facilitating program reading;

[0055] Generate a header file according to the table structure for easy calling;

[0056] Write the foreground application program and generate a dynamic link library file for client operation;

[0057] Write a background service program and compile it for the application program to access the database server;

[0058] The client calls the background service program to realize data communication.

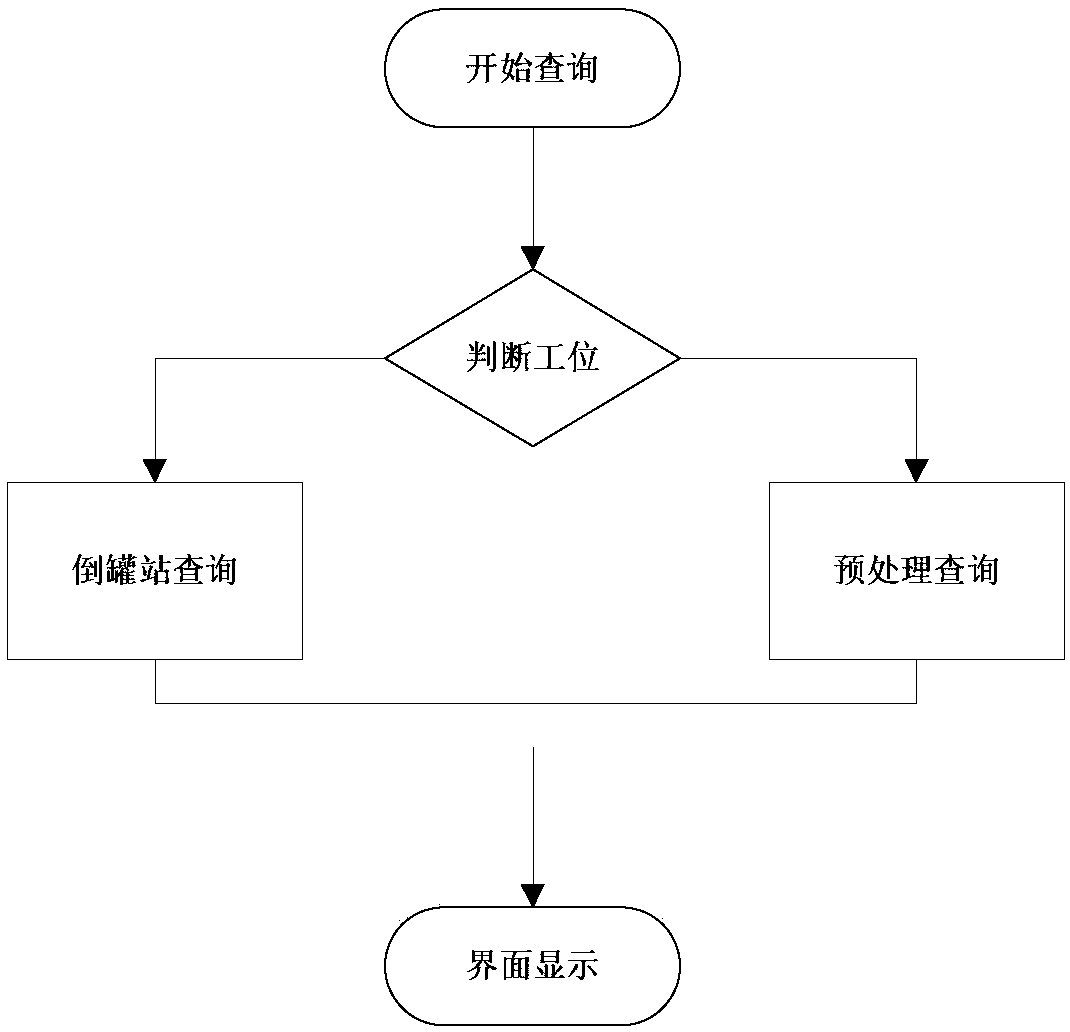

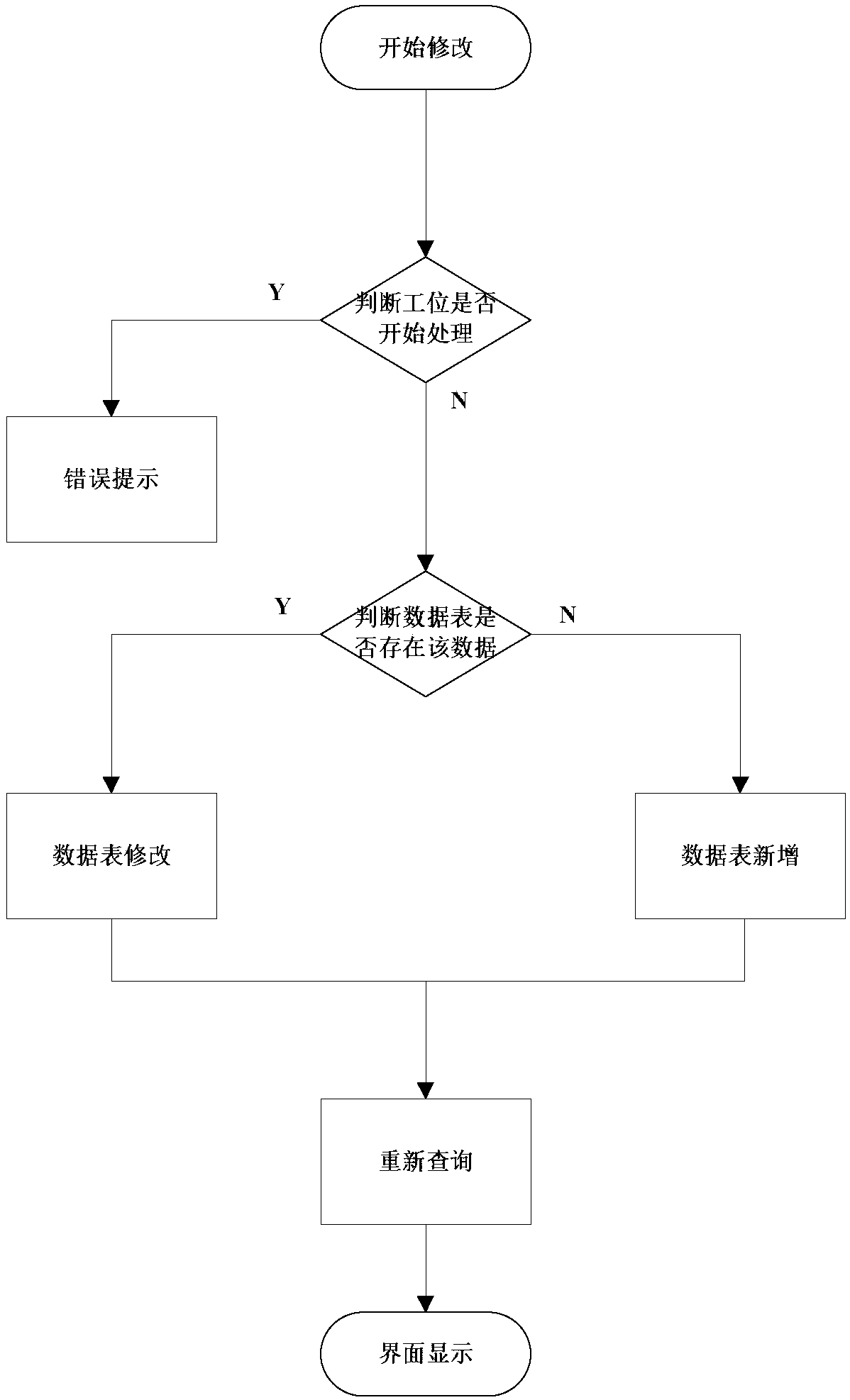

[0059] In order to meet the production needs of the steelmaking plant, the present invention uses VS2008C# to write the front desk, PRO*C to write the background, and ORACLE data table support to write, including raw material plan query, tank dumping signal simulation, prepro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap