A method for preparing highly magnetic sintered NdFeB by atmosphere diffusion

A NdFeB, high magnetic technology, applied in the direction of magnetic objects, magnetic materials, electrical components, etc., can solve the problems of volatilization, achieve the effect of refining grains, increasing coercive force, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation process of highly magnetic sintered NdFeB prepared by atmosphere diffusion is as follows:

[0023] Step 1: Orient the NdFeB magnetic powder under a 1.2T magnetic field;

[0024] Step 2: Carry out semi-densification sintering of the compact in a vacuum sintering furnace, the sintering temperature is 950°C, the heat preservation is 1.5h, and the density is 90%;

[0025] Step 3: Put sintered NdFeB (40g) with a density of 90% in the quartz tube, add 0.1g of sulfur powder into the quartz tube, and then vacuum seal the quartz tube to a vacuum degree of 10 -2 Above Pa;

[0026] Step 4: Place the sample of the vacuum quartz sealed tube in a sintering furnace for vacuum sintering, the sintering temperature is 1040°C, heat preservation for 3h, and then go through primary tempering at 850°C for 3h and secondary tempering at 550°C for 5h;

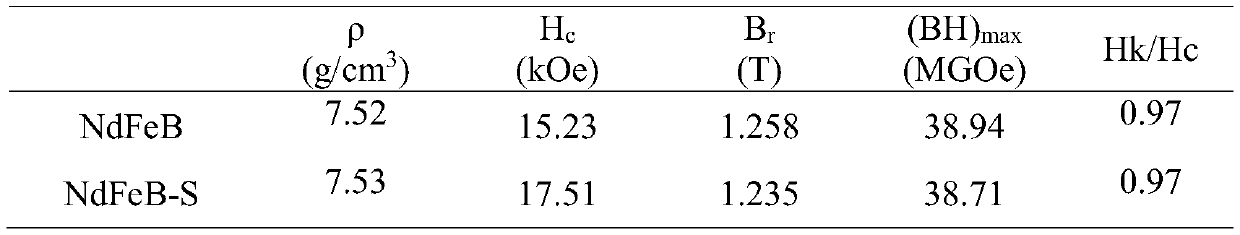

[0027] Step 5: The prepared NdFeB magnet was subjected to VSM magnetic performance measurement, and the results are shown in Ta...

Embodiment 2

[0033] A preparation process of highly magnetic sintered NdFeB prepared by atmosphere diffusion is as follows:

[0034] Step 1: Orient NdFeB magnetic powder under a magnetic field of 2.0T;

[0035] Step 2: Carry out semi-densification sintering of the green compact in a vacuum sintering furnace, the sintering temperature is 950°C, the heat preservation is 3 hours, and the density is 95%;

[0036] Step 3: Put sintered NdFeB (35g) with a density of 95% in the quartz tube, add 0.03g of phosphorus powder into the quartz tube, and then vacuum seal the quartz tube to a vacuum degree of 10 -2 Above Pa;

[0037] Step 4: Place the sample of the vacuum quartz sealed tube in a sintering furnace for vacuum sintering, the sintering temperature is 1050°C, heat preservation for 5h, and then go through primary tempering at 885°C for 2h and secondary tempering at 500°C for 6h;

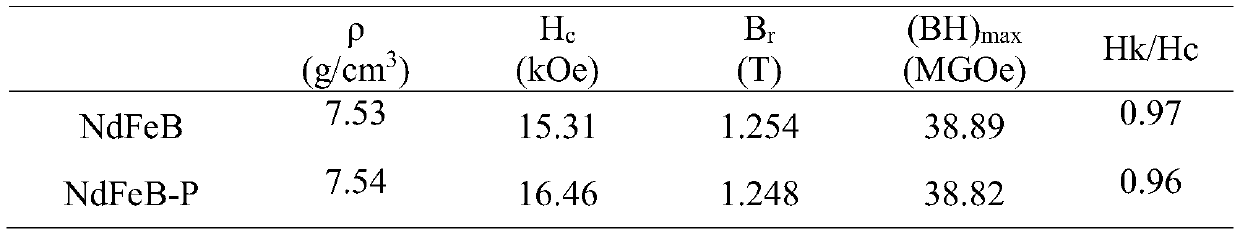

[0038] Step 5: The prepared NdFeB magnet was subjected to VSM magnetic performance measurement, and the results ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com